Oil tank reinforced earth protective body and construction method thereof

A technology of reinforced soil and protective body, applied in the field of oil tank reinforced soil protective body and its construction, can solve the problems of difficulty in meeting the requirements of covering soil standards, inability to use mechanical compaction, unstable structure, etc. The effect of reducing the amount of land and earthwork and saving land area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

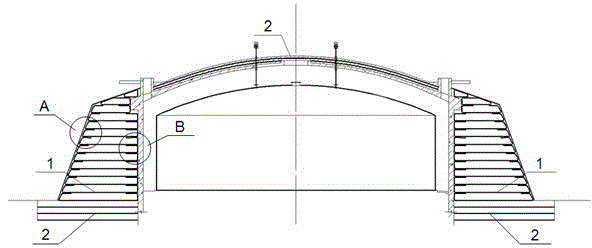

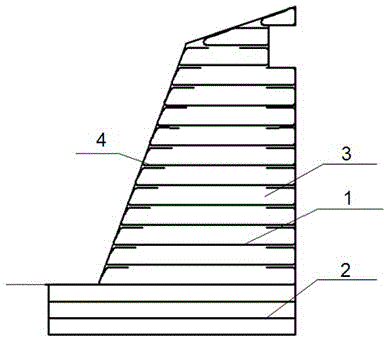

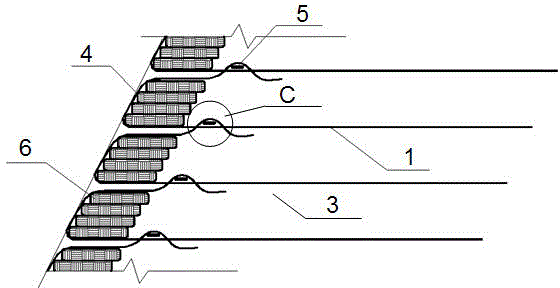

[0022] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a foundation and an oil tank reinforced soil protective body, the foundation includes a three-layer bidirectional geogrid 2 on the original soil bearing layer, and the bidirectional geogrid 2 is filled with filler 3; the oil tank reinforced soil protective body adopts The geogrid layer and the filler layer are alternately pressed together; the oil tank is surrounded by unidirectional high-density geogrid 1, and the outer side of the next layer of unidirectional geogrid 1 is connected to the upper layer by connecting rods 5, and the inner side is directly connected to the upper layer. The upper layer is compacted, and the length of 1.5 meters is reserved at both ends of the one-way geogrid 1, and the soil bags 6 are stacked at both ends for compaction. 4. The vault of the oil tank adopts a two-layer bidirectional geogrid 2, and the bidirectional geogrid 2 is filled wi...

Embodiment 2

[0024] Take an oil tank reinforced soil protection project in Shandong as an example: a geogrid reinforced turn-up flexible structure is adopted. After calculation by the design software, if the safety and stability requirements of the national standard are met, the type of reinforcement material and the length of the reinforcement are determined. The bottom of the main body of the reinforced soil protection body for the oil tank is covered with one-way grids, the slope of the outer wall is wrapped with planting soil, and turf is laid for wall greening. Two layers (30cm each layer) of backfill shall be compacted mechanically or manually. From the second layer, the outside of the layer is connected to the upper layer with connecting rods and tightened with the grid on the inside of the same layer (near the wall), and then the planting soil is wrapped, the turf is laid, and the filling is compacted until the design elevation. The last layer of one-way geogrid is turned up and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com