Roadside support method for tight roof constant-resistance yielding roadway

A technology of hard roof and roadside support, which is used in earth-moving drilling, pillar/support, wellbore lining, etc., can solve the problem that the support has not been well solved, and the applicability of gob-side entry retention has not formed a perfect theoretical system, etc. problems, to achieve the effect of eliminating roadside support failure, meeting safety and reliability requirements, and strong on-site applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

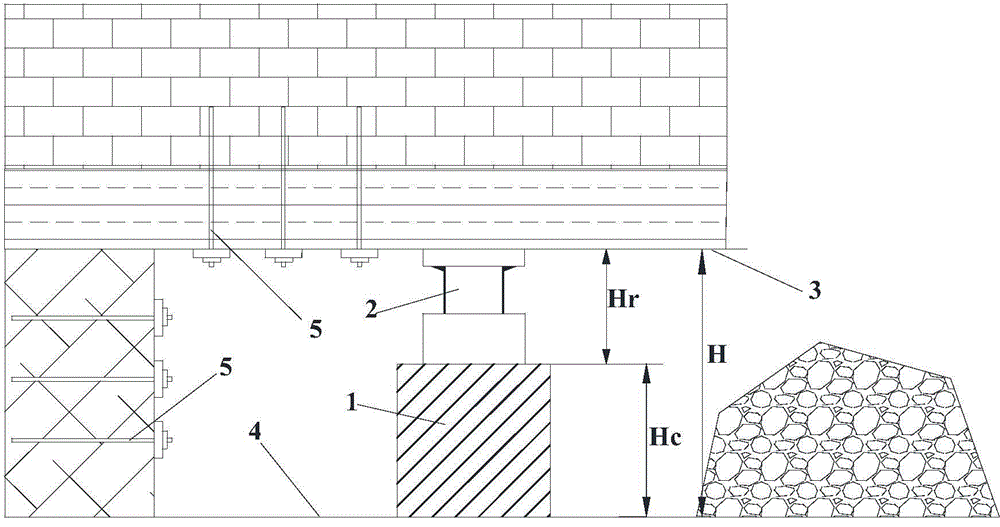

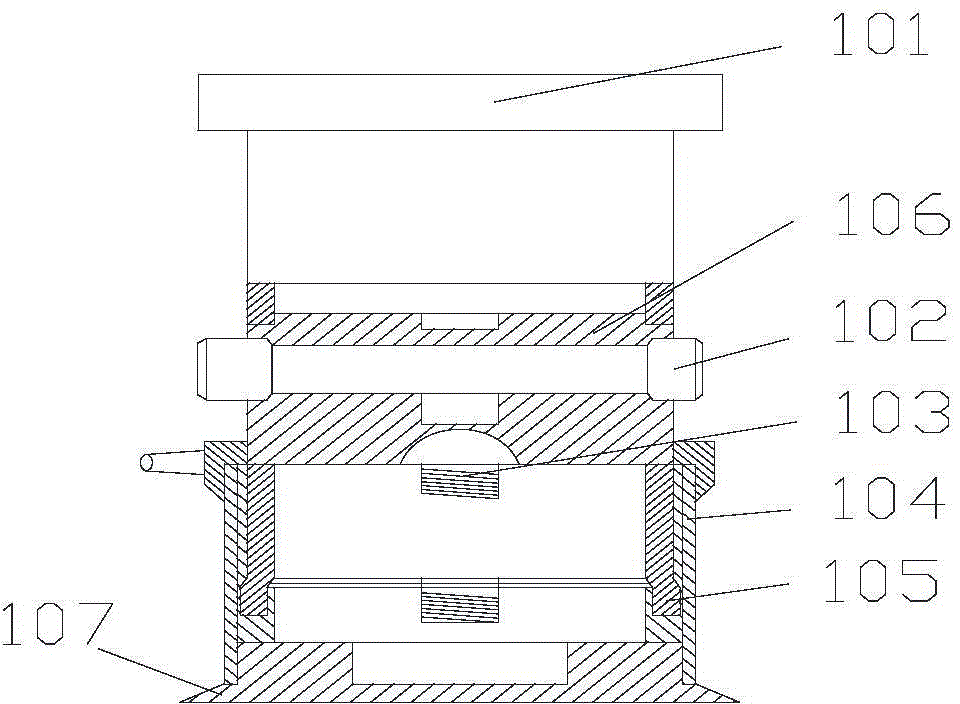

[0067] Take the roadway with a hard roof in a coal mine, and the structure of the constant resistance pressure pad as an externally injected single hydraulic prop with a short and thick live column as an example:

[0068] The height of the roadway is H=2.5m, the span is 3.8m, and the sinkage of the roof is 0.8m; A certain number of metal pressure anchor rods are evenly installed.

[0069] When supporting the gob-side retaining roadway of the hard roof, the supporting method includes the following steps:

[0070] (1) In the roadside support process of the roadway with a hard roof along the gob-side retaining, firstly, according to the expected deformation of the roadway, design the constant resistance yield height Hr=0.8m and the height of the roadside filling body Hc=H-Hr= 2.5m0.8m=1.7m.

[0071] (2) Then build a high-strength filling body (concrete column) on the floor on both sides of the roadway, with a compressive strength of 25MPa, a width of 1.5m, and a height of 1.7m....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com