Guide mechanism and electro-mechanical actuator thereof

A technology of guiding mechanism and linear guide, applied in mechanical equipment, transmission device, belt/chain/gear, etc., can solve the problems of small bearing capacity of guiding mechanism and large friction force of guiding mechanism, so as to improve the bearing capacity and reduce friction. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments.

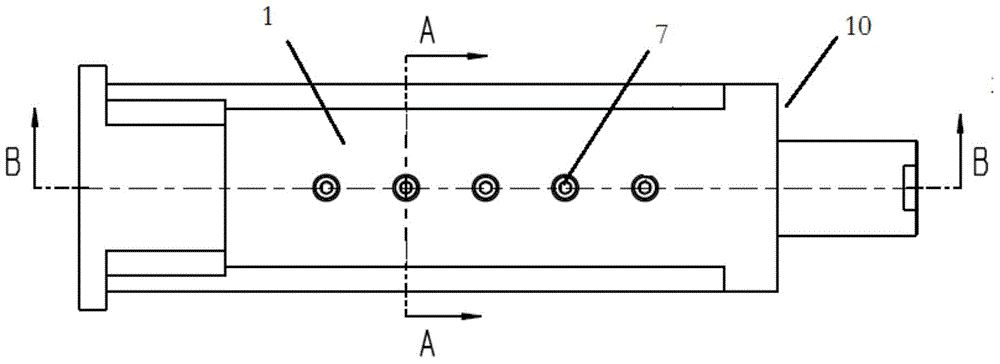

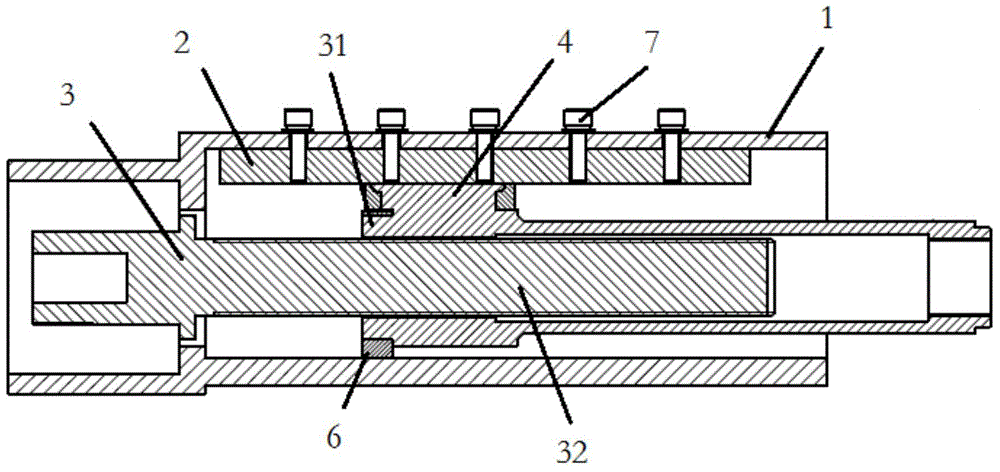

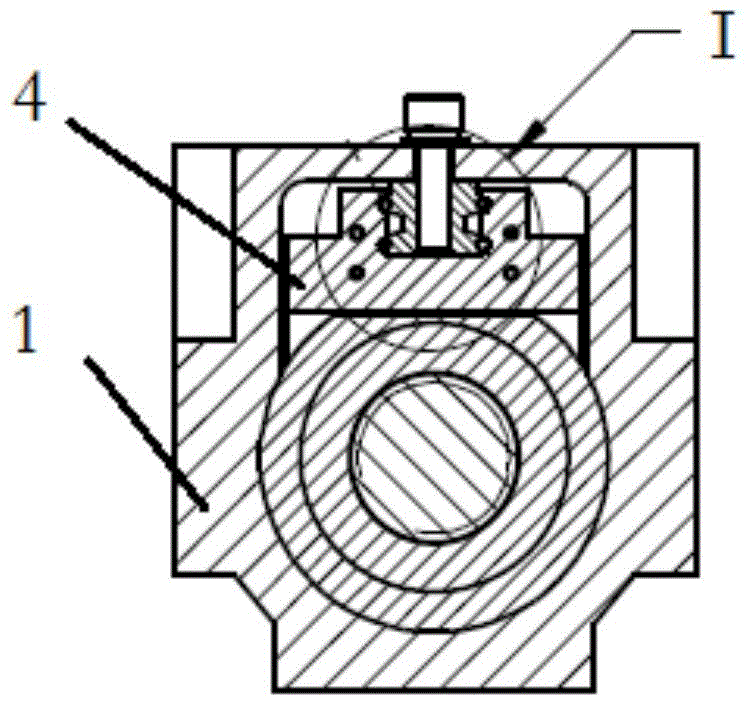

[0021] Such as Figure 1 to Figure 4 As shown, the present invention discloses a guiding mechanism. The guiding mechanism 10 includes a housing 1, a linear guide 2, a ball screw pair 3, a slider 4, and a ball 5. The inner wall of the housing 1 is provided with a groove or A groove is surrounded by multiple walls of the housing 1, the linear guide 2 is located in the groove, and is fixedly connected to the housing 1 by screws, the ball screw pair 3 is arranged in the housing 1, the slider 4 and the ball screw The screw nut 31 in the pair 3 is fixedly connected, and the sliding block 4 can move relatively along the linear guide 2. More specifically, the sliding block 4 can relatively slide along the linear guide 2. The ball 5 is arranged between the slider 4 and the linear guide rail 2. Due to the rolling of the ball 5, the relative moveme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com