Precision calibrating method of infrared thermometer with wide temperature range

A technology of infrared thermometer and calibration method, which is applied in radiation pyrometry, instruments, measuring devices, etc., can solve the problems of inconvenient data collection, exceeding accuracy requirements, and large test errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

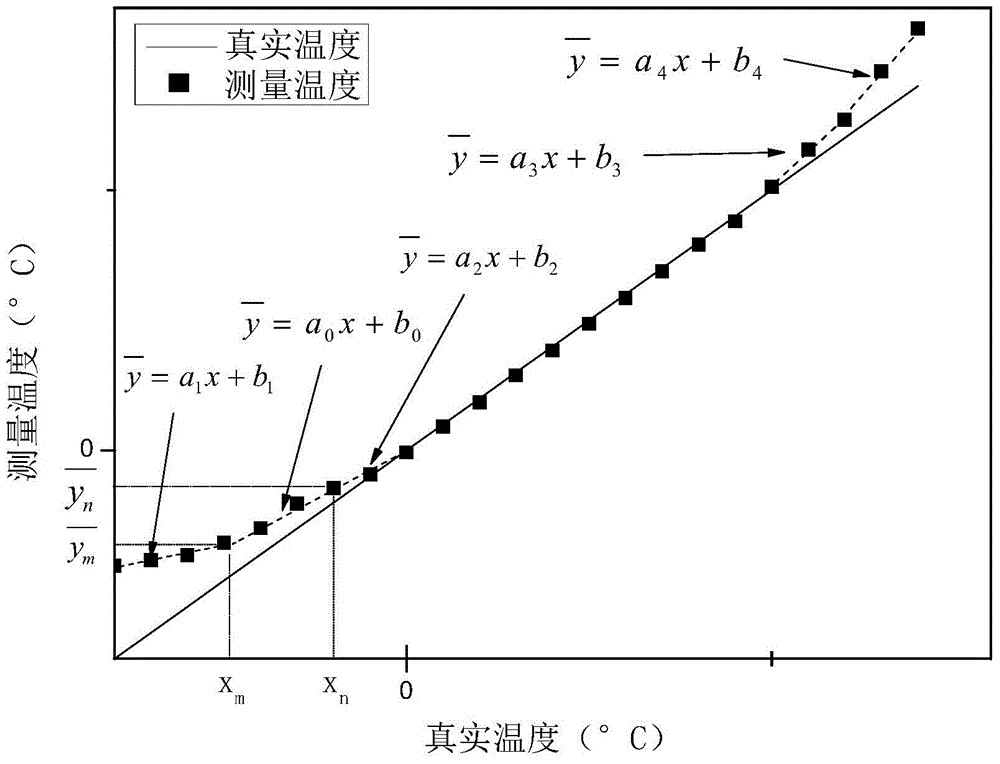

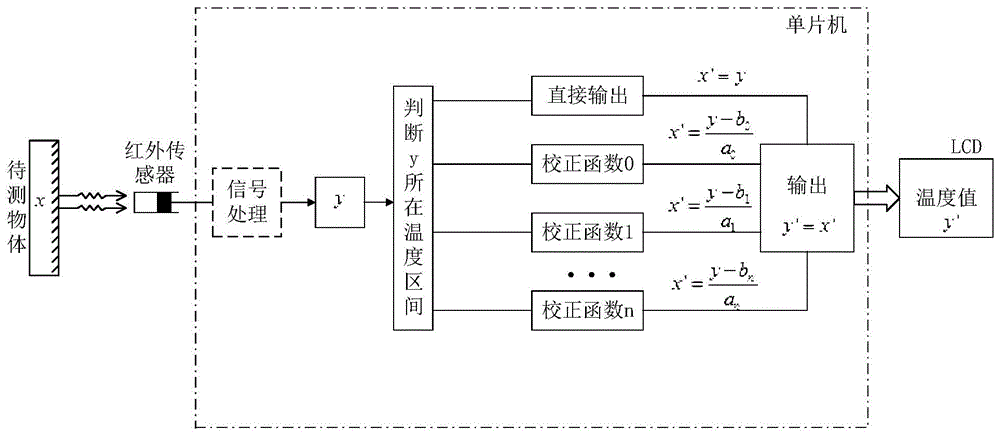

[0032] figure 2 It is the temperature calibration flow chart of the infrared thermometer. In the figure, x is the real temperature of the object; y is the initial temperature value obtained after the microcontroller reads the sensor signal, x' is the calibrated temperature, and y' is the calibrated temperature displayed on the LCD. temperature value. When calibrating the infrared thermometer, determine its temperature range according to the size of y, and judge whether y needs to be corrected. If not, then x'=y, and the displayed temperature y' is equal to the corrected temperature x'. That is, y'=x'=y; otherwise, substitute y into the corresponding correction function to obtain a calibration value x' that is closer to the real temperature than y, that is, the corrected display temperature The values of A and B are determined by the temperature range of y, and the corrected displayed temperature error is ±1°C. Therefore, after correction by the least square method, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com