A kind of circular tube lateral slamming device and its test method

A round pipe and supporting device technology, applied in the field of dynamic test and testing system, can solve the problems of difficulty in analysis and research, uncertainty of damage degree, non-unique impact results, etc., and achieve adjustable span, adjustable pipe specifications, and slamming radius. adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

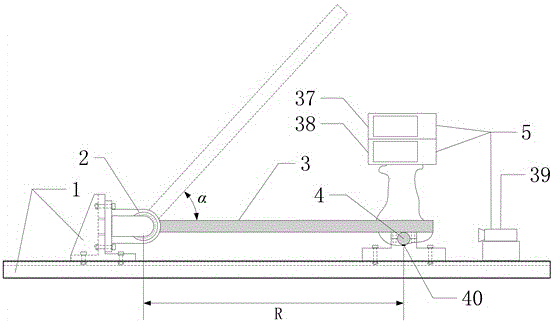

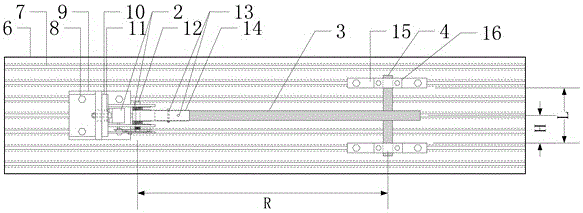

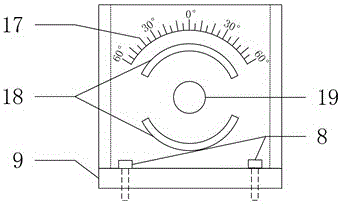

[0071] Such as Figure 10 As shown, when the active tube rotating table 10 is rotated to 0°, the strike plane of the active tube 3 is perpendicular to the driven tube 4, that is, the active tube 3 and the driven tube 4 collide orthogonally. In this case, the active tube 3 does not deflect after colliding with the driven tube 4, but bounces back in the original path.

[0072] Since the driving tube 3 is parallel to the roller shaft clamping groove 30 at the initial moment, and the roller shaft clamping groove 30 is located on the line connecting the two balls 29, that is, the driving tube 3 and the rolling balls 29 are in a horizontal position at the initial moment. In the process of lifting the active tube 3, the ball 29 is in contact with the elevation angle rotating disc 27, and the motor 24 can apply torque to lift the active tube 3. When the active tube 3 is lifted to 60°, the position of the ball 29 is just at the position of the slot 34 of the elevation angle rotating di...

Embodiment 2

[0074] Such as Figure 11 As shown, when the active tube rotating table 10 is rotated to 30°, the strike plane of the active tube 3 and the driven tube 4 are at 60°, that is, the active tube 3 and the driven tube 4 collide at 60°. In this case, the active tube 3 deflects after colliding with the driven tube 4 and pops up to the other side.

[0075] Because the loading device 2 is located on the active tube rotating table 10, when the active tube rotating table 10 rotates, the loading device 2 also rotates, and its working principle does not change. The angle of rotation in the 60° swing plane controls the angle at which the torsion spring 25 rotates. Therefore, changing the elevation angle of the rotating disk 27 can also achieve oblique impact effects at different speeds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com