A device for testing ultrasonic vibration extra-long life fatigue of a material under a high-pressure state

An ultrasonic vibration, ultra-long life technology, applied in the direction of measuring devices, analytical materials, instruments, etc., to achieve the effect of convenient experimental operation and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with this embodiment, but the embodiments of the present invention are not limited thereto.

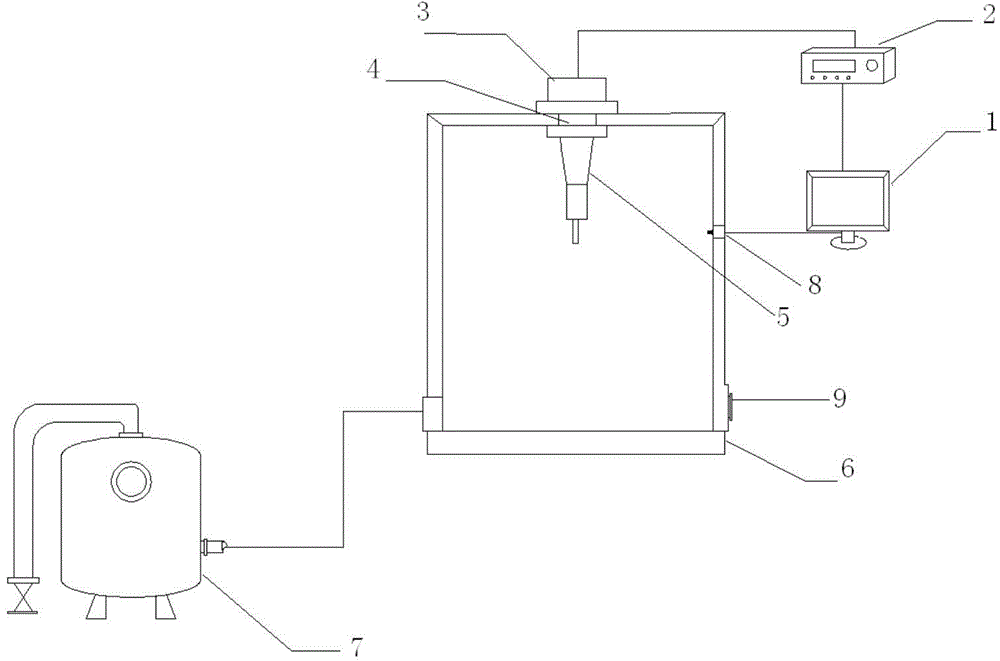

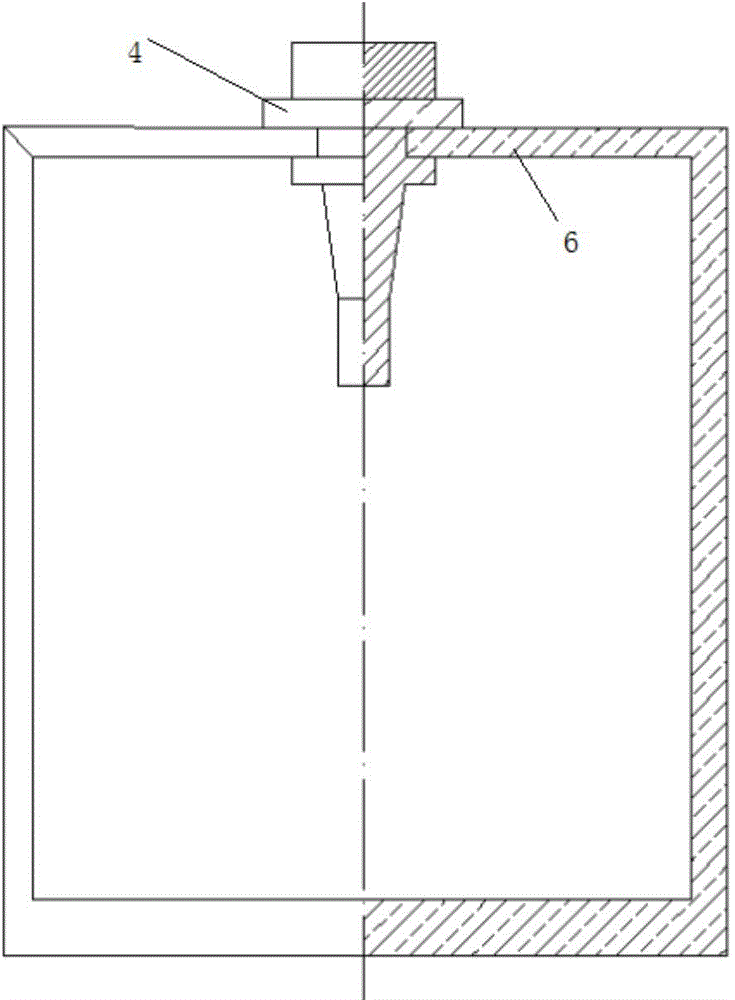

[0018] As shown in the figure, the experimental device includes a material ultrasonic fatigue testing unit and a high-voltage applying device. The ultrasonic fatigue test unit includes a computer system connected in sequence, an energy generator, a piezoelectric ceramic transducer, a horn fixedly connected to the lower end, and an extension rod coaxial with the horn at the output end of the horn. The extension rod is connected to the test piece, and the high-pressure pressure tank is coupled with the horn through screws. The high-pressure pressure tank is equipped with a pressure relief switch and a pressurizing device connected to a pressure pump. The pressurizing device can display the pressure inside the pressure tank through a pressure sensor.

[0019] The working principle of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com