A piston type constant temperature calorimeter

A technology of piston type and calorimeter, which is applied in the direction of material heat development, etc., can solve the problems of slow water inflow, probe pollution, etc., and achieve the effects of constant water volume, easy operation, and constant temperature of the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

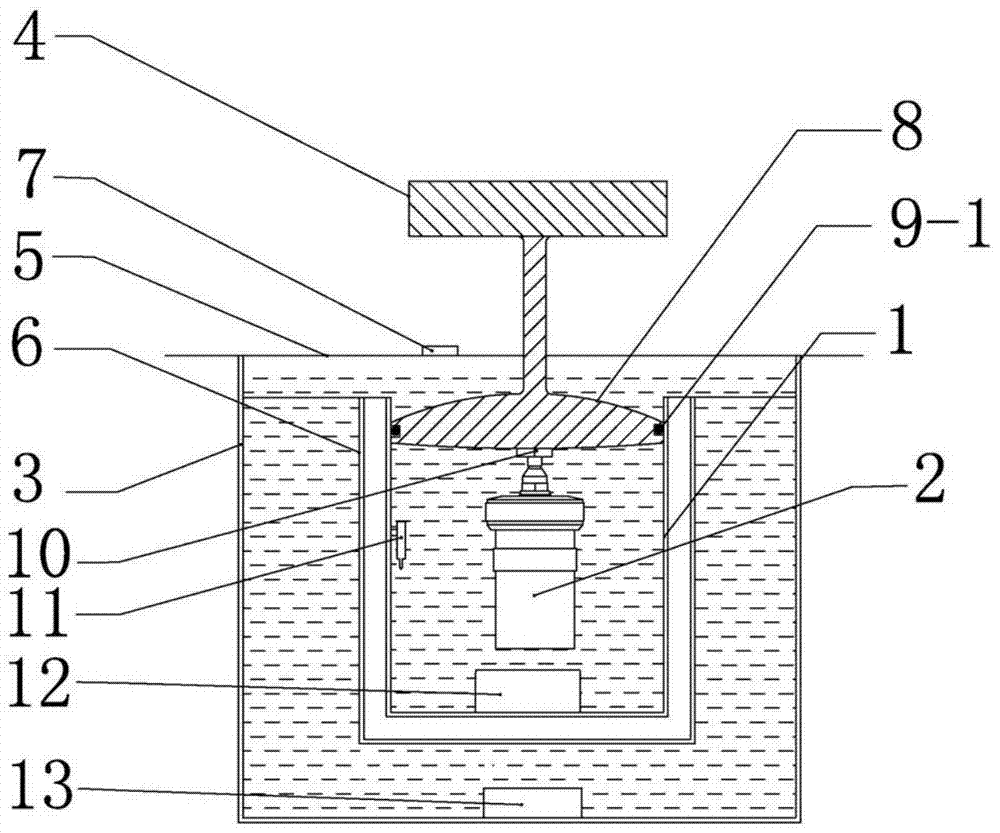

[0020] Such as figure 1 As shown, a piston-type constant temperature calorimeter includes an inner cylinder 1, an oxygen bomb 2, an outer cylinder 3, a machine cover 4 and a casing 5, the inner cylinder 1 is placed in the outer cylinder 3, and the inner cylinder 1 is placed in the outer cylinder 3. A middle cylinder 6 is provided between the cylinder 1 and the outer cylinder 3, the inner cylinder 1 and the middle cylinder 6 are sealed and hollowly connected as a whole, and the inner cylinder 1 and the middle cylinder 6 are completely submerged in the outer cylinder 3 in the water. Described machine cover 4 is installed on the casing 5 by hinge, is provided with piston 8 below machine cover 4, and the caliber of described piston 8 is slightly smaller than inner diameter of inner cylinder 1, and shape is consistent with inner cylinder 1 section shape, and the upper and lower surfaces of piston 8 Both are arc-shaped convex surfaces, which are convenient for the piston 8 to enter...

Embodiment 2

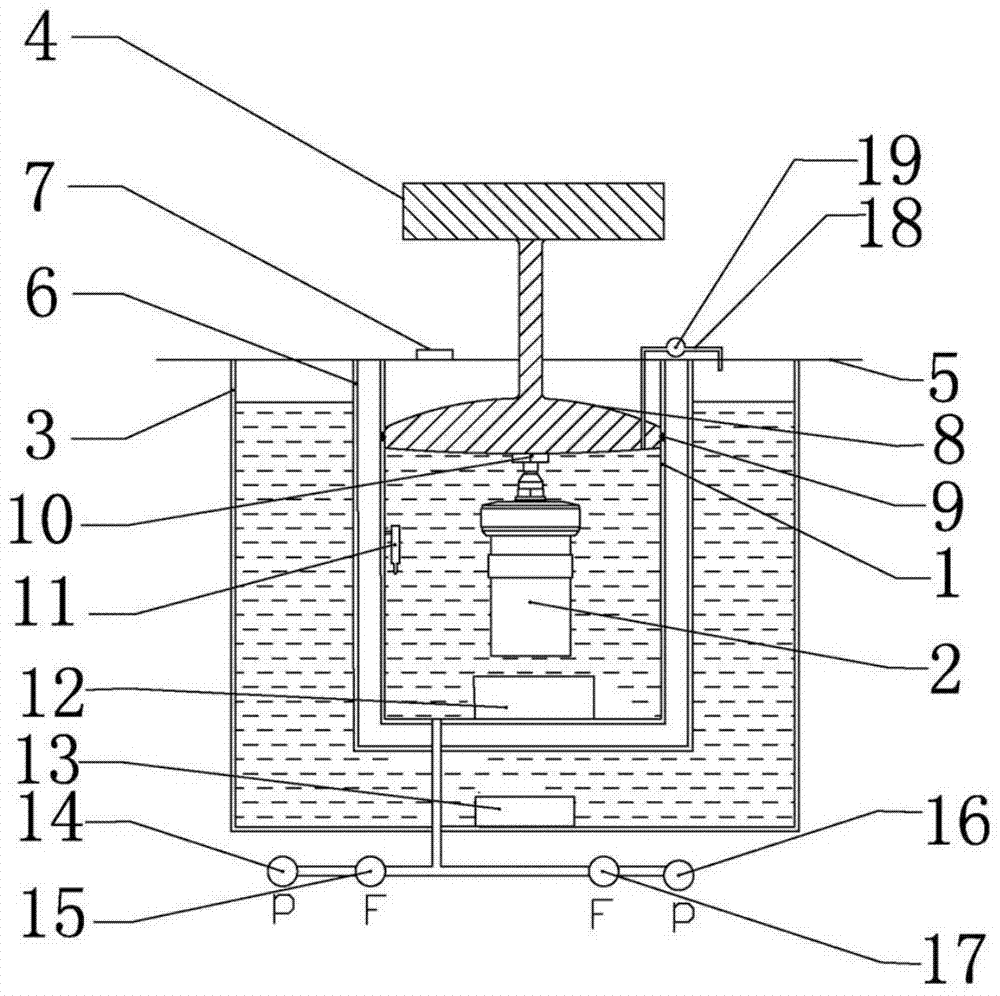

[0023] Such as figure 2 As shown, a piston-type constant temperature calorimeter includes an inner cylinder 1, an oxygen bomb 2, an outer cylinder 3, a machine cover 4 and a casing 5, the inner cylinder 1 is placed in the outer cylinder 3, and the inner cylinder 1 is placed in the outer cylinder 3. A middle cylinder 6 is provided between the cylinder 1 and the outer cylinder 3, and the space between the inner cylinder 1 and the middle cylinder 6 is hollow. The machine cover 4 is installed on the casing 5 through a lifting mechanism, and the bottom of the machine cover 4 A piston 8 is provided, and the diameter of the piston 8 is slightly smaller than the inner diameter of the inner cylinder 1, and its shape is consistent with the section shape of the inner cylinder 1. 8. The sticky water on the upper and lower surfaces of the inner cylinder 1 can be quickly dripped clean. The bottom of the piston 8 is provided with an ignition electrode 10 through which the sample in the oxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com