Analysis testing method for foam characteristic excess reason of power steam turbine engine oil

A technology of steam turbine oil and test method, applied in the direction of material inspection products, etc., can solve the problems of excessive foam, accelerated oil deterioration speed, poor oil addition effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

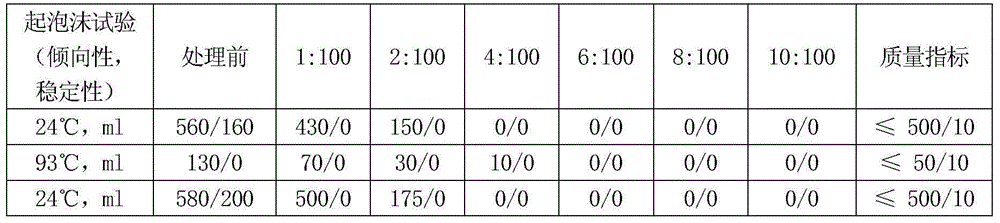

[0016] According to step 1 of the present invention, get the steam turbine oil sample that the foam characteristic of A power plant exceeds the standard, the microporous polarity inducing adsorbent and this oil sample mass ratio are respectively 1:100, 2:100, 4:100, 6:100, 8 :100, 10:100 oil samples, stirred at 60°C for 45 minutes, filtered, removed the adsorbent and retained the processed samples, and measured their foam characteristic indicators respectively. The test results are shown in Table 1.

[0017] Table 1A Comparison of foam characteristic index results of oil products before and after treatment with adsorbent in power plant turbine oil

[0018]

[0019] According to the above test data, after the regeneration treatment test with the mass ratio of adsorbent to sample at 4:100, the problem of excessive foam of the sample was completely solved. Therefore, it can be determined that the excessive oil foam of the steam turbine in power plant A is affected by the dete...

Embodiment 2

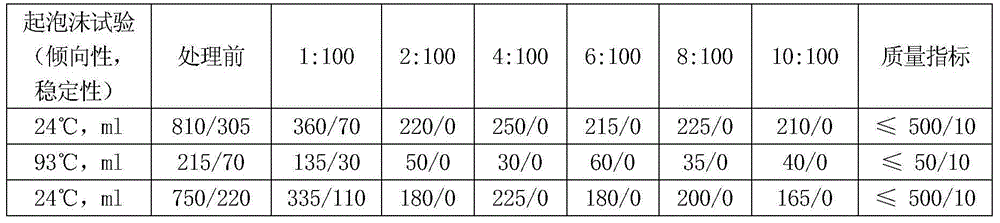

[0021] According to step 1 of the present invention, get the steam turbine oil sample that B power plant foam characteristic exceeds standard, respectively microporous polarity inducing adsorbent and this oil sample mass ratio are 1:100, 2:100, 4:100, 6:100, 8 :100, 10:100 oil samples, stirred at 60°C for 45 minutes, filtered, removed the adsorbent and retained the processed samples, and measured their foam characteristic indicators respectively. The test results are shown in Table 2.

[0022] Table 2B Comparison of the results of the foam characteristics of the oil before and after the treatment of the turbine oil in the power plant

[0023]

[0024] According to the above test results, the problem of excessive foam characteristics of steam turbine oil in power plant B has not been completely solved, but the foam characteristic indicators have improved. According to the analysis method introduced in the present invention, according to step 2 of the present invention, add ...

Embodiment 3

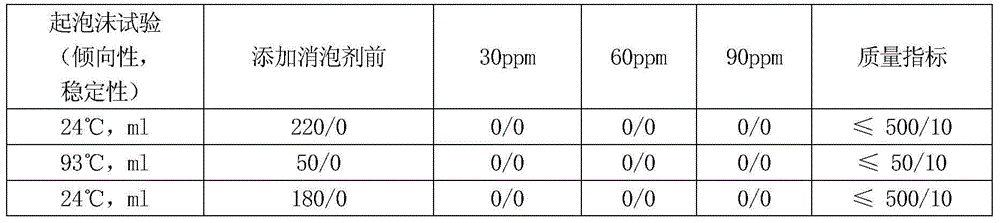

[0029] According to step 1 of the present invention, get the steam turbine oil sample that C power plant foam characteristic exceeds standard, respectively microporous polarity inducing adsorbent and this oil sample mass ratio are 1:100, 2:100, 4:100, 6:100,8 :100, 10:100 oil samples, stirred at 60°C for 45 minutes, filtered, removed the adsorbent and retained the processed samples, and measured their foam characteristic indicators respectively. The test results are shown in Table 4.

[0030] Table 4C Comparison of the results of the foam characteristics of the oil before and after the treatment of the steam turbine oil in the power plant

[0031]

[0032] According to the above test results, the turbine oil of C power plant is slightly improved after being treated with adsorbent, but not obviously. According to the analysis method introduced in the present invention, according to step 2 of the present invention, add 30ppm, 60ppm, 90ppm non-silicon high-efficiency defoamer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com