An industrial control signal detection system and detection method

A signal detection and signal technology, applied in the field of industrial control signal detection, signal detection system, industrial control signal detection system, can solve the problem of excessive electrical quantity, failure to achieve real-time automatic alarm and monitoring, manual data correlation analysis of historical data Comparing and analyzing problems such as incompetence to achieve the effect of solving information security problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical problems solved by the present invention, the technical solutions adopted, and the technical effects obtained easy to understand, the specific implementation manners of the present invention will be further described below in conjunction with the specific drawings.

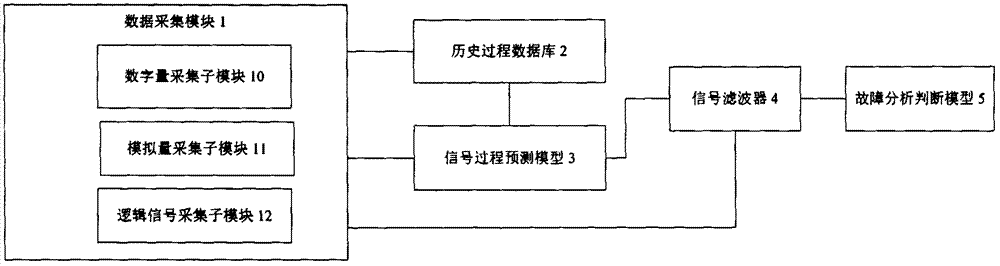

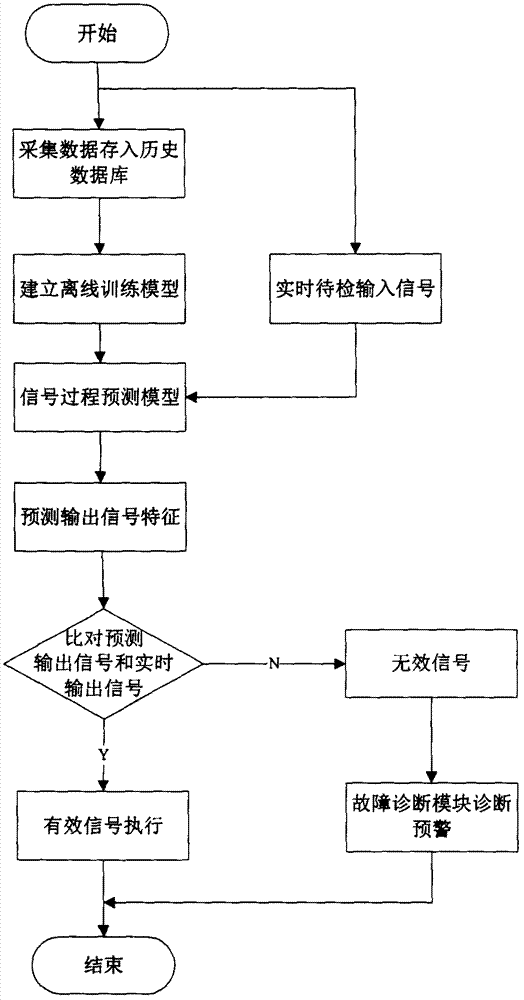

[0028] refer to figure 1 , the present invention provides a kind of industrial control signal detection system, comprising: data acquisition module 1, is used for collecting the real-time state data of the electrical characteristic of equipment; This data acquisition module obtains the real-time state of the electrical characteristic of hardware equipment in the system, mainly includes Voltage, current, frequency, etc. These values can be collected through PLC or DCS system, and only the train control system needs to provide the collection interface. Preferably in the present invention, the data acquisition module 1 includes a digital quantity acquisition submodule 10 , an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com