Dragging-resistant grinding-resistant mobile cable

A mobile cable and drag-resistant technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of poor bending performance, heavy weight, and no reinforcements, etc., to achieve improved bending resistance, small weight, The effect of low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

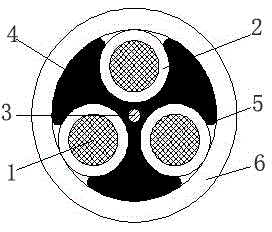

[0017] like figure 1 As shown, a drag-resistant and rolling-resistant mobile cable according to the present invention includes a cable core, the cable core is wrapped around a tape layer 5, and the outermost layer is extruded into an outer sheath 6; the cable core is composed of It is composed of several insulated wire cores and saddle-shaped filling strips separating the insulated wire cores; the insulated wire core is composed of a conductor 1 and an insulating layer 2 extruded outside the conductor 1 .

[0018] The saddle-shaped filling strip is composed of the central aramid yarn 3 and the saddle-shaped rubber strip 4 extruded outside the aramid yarn; the saddle-shaped rubber strip 4 is provided with a plurality of rubber band ridges, and every two rubber bands A groove is formed between the ridges to separate the insulated cores;

[0019] The conductor 1 is fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com