A Repairing Method for Insulation Defects of Power Cable Thermoplastic Material

A thermoplastic material and insulation defect technology, which is applied in the direction of insulation/armored cable repair equipment, can solve the problems of defect expansion, waste, and low reliability, and achieve the effect of ensuring long-term safe operation and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

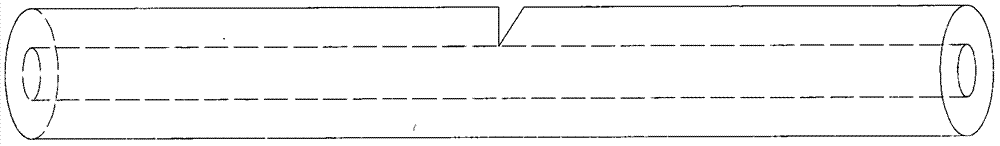

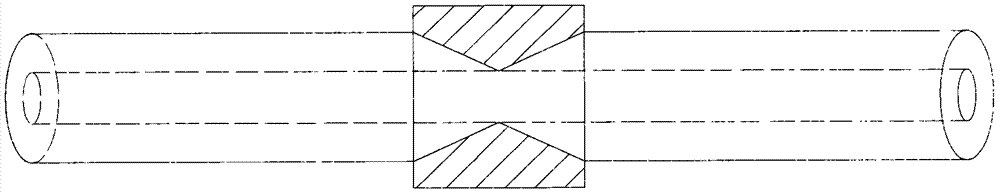

[0025] Embodiment 1: A method for repairing insulation defects of thermoplastic materials of power cables, characterized in that it comprises the following steps: (1) slotting at the defect of the insulation layer; (2) preparing rubber strips; (3) wrapping glue in the annular groove (4) Put the wire core wrapped with rubber strip repair layer into the shaping mold; (5) extrusion molding; (6) repair the interface; (7) complete the repair after detection; among them,

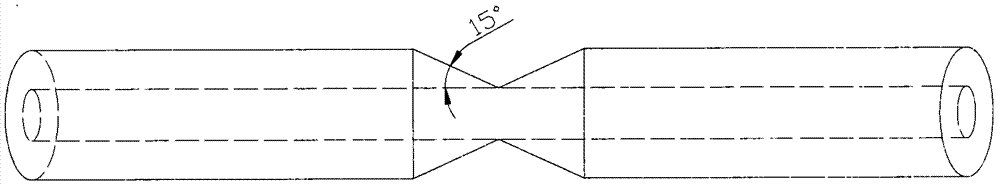

[0026] (1) Grooving at the defect of the insulating layer: such as figure 2 As shown in Fig. 1, an annular groove with an isosceles triangular cross-section is opened at the defect of the insulating layer of the wire core with a circular planer. The advantage of equal sides is to ensure the quality of the subsequent process and prevent the formation of stress concentration here. . The angle between the waist of the isosceles triangle and the center line of the core is 15 degrees. If the degree is too large, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com