Inverse direct power control method of grid connection converter

A power control and converter technology, which is applied in the field of reverse direct power control of grid-connected converters, can solve problems such as large amount of computation, high dependence on mathematical model parameters, and weak robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

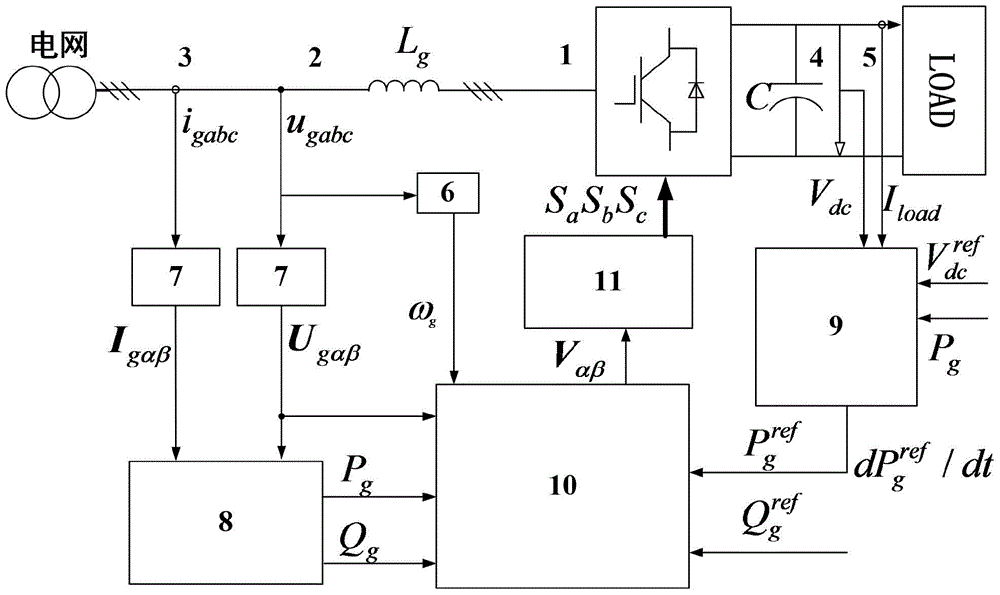

[0036]The grid-connected converter back-stepping direct power control system in this embodiment includes a voltage source type grid-connected converter 1, a voltage sensor 2 for detecting the voltage of the three-phase grid, and a current Hall sensor 3 for detecting the three-phase current. The voltage sensor 4 for detecting the DC bus voltage, the current Hall sensor 5 for detecting the load current on the DC side, and the control loop for adjusting the output active and reactive power of the grid-connected converter. The control loop is composed of a feedback signal processing channel and a forward control channel, wherein the feedback signal processing channel includes a digital phase-locked loop module 6, which is used to obtain the stator voltage in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com