Hoisting fixture of motor stator

A motor stator and hoisting technology, which is applied in the manufacture of stator/rotor bodies, etc., can solve the problems of low production efficiency, insufficient space utilization, and no effective solutions, and achieve the effect of reducing the number of placements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

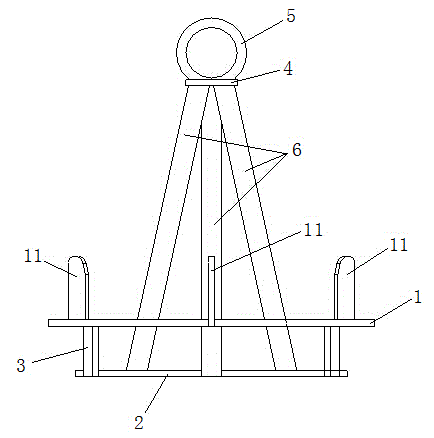

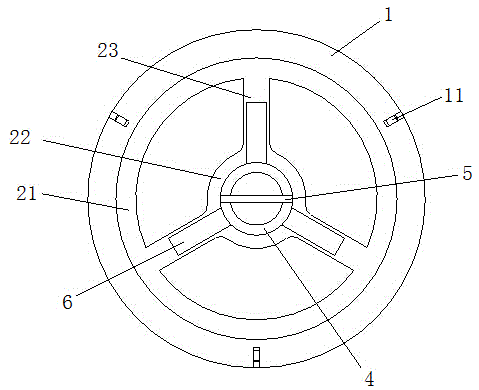

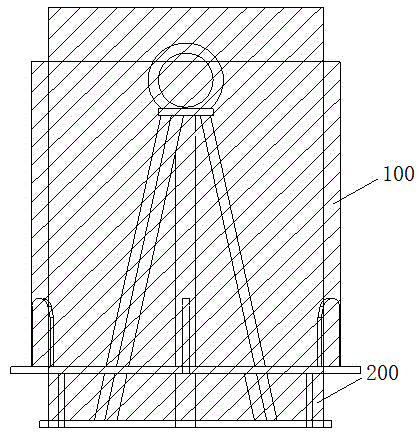

[0015] Such as figure 1 , figure 2 The shown motor stator hoisting tooling includes a supporting part used to place the motor stator shell 100 and a hoisting part connected to the supporting part. The supporting part includes a circular support plate 1 arranged in a horizontal direction. A base 2 is provided parallel to the bottom of the base. The base 2 includes an outer ring 21 and an inner ring 22 arranged concentrically. The outer ring 21 and the inner ring 22 are connected by a first steel plate 23. The diameter of the outer ring 21 is smaller than the diameter of the support plate 1. The outer ring 21 and the support plate 1 are connected by the second steel plate 3, that is, there is a certain height difference between the outer ring and the support plate, and the first steel plate 23 between the outer ring 21 and the inner ring 22 is connected with the hoisting pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com