Method for weakening cogging torque of permanent magnet synchronous generator

A technology of cogging torque and permanent magnet synchronization, which is used in wind power generation, manufacturing of stator/rotor bodies, sustainable buildings, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The preferred embodiments are described in detail below in conjunction with the drawings.

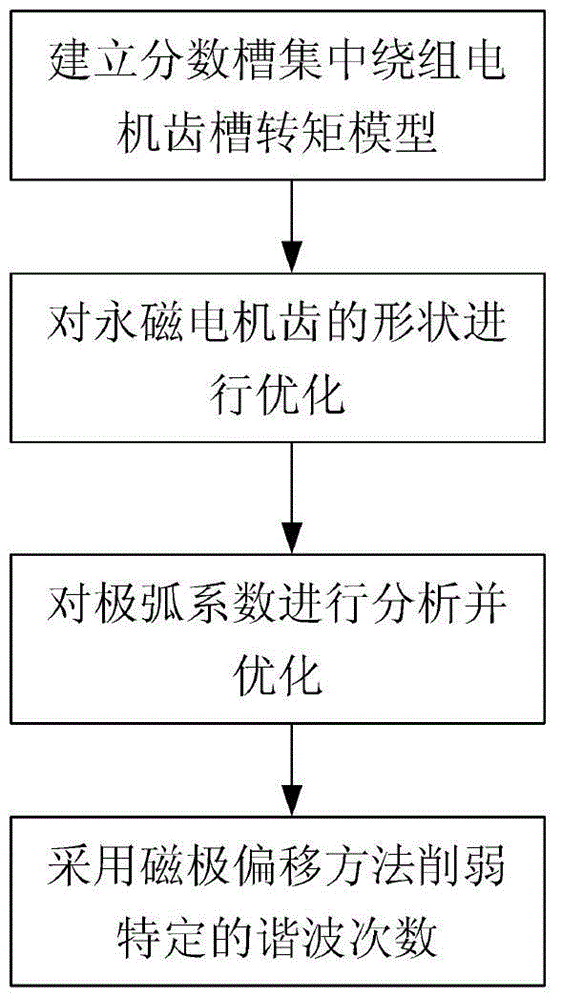

[0054] A method used to weaken the cogging torque of a permanent magnet synchronous generator, such as figure 1 Shown, including:

[0055] Step 1. Select a permanent magnet motor with concentrated winding with fractional slots, determine the number of slot poles of the motor, and establish a cogging torque model of the motor with concentrated winding with fractional slots;

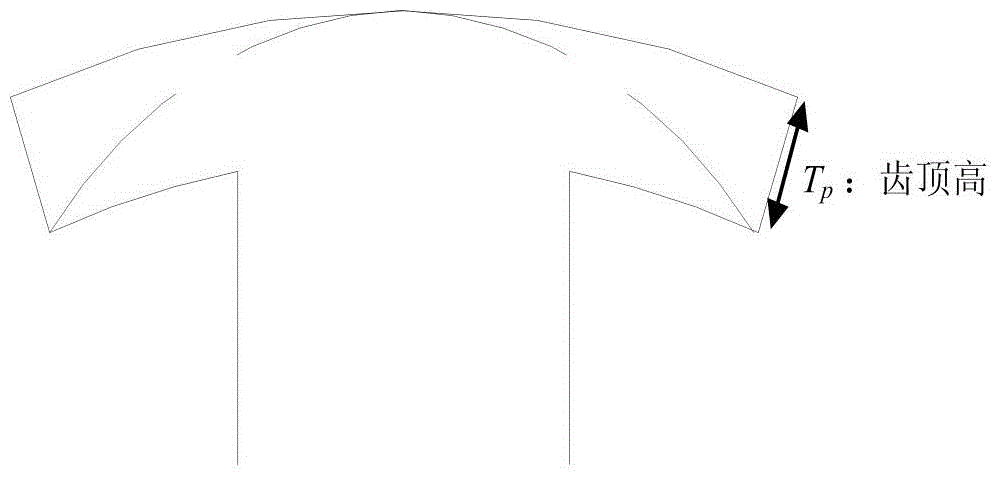

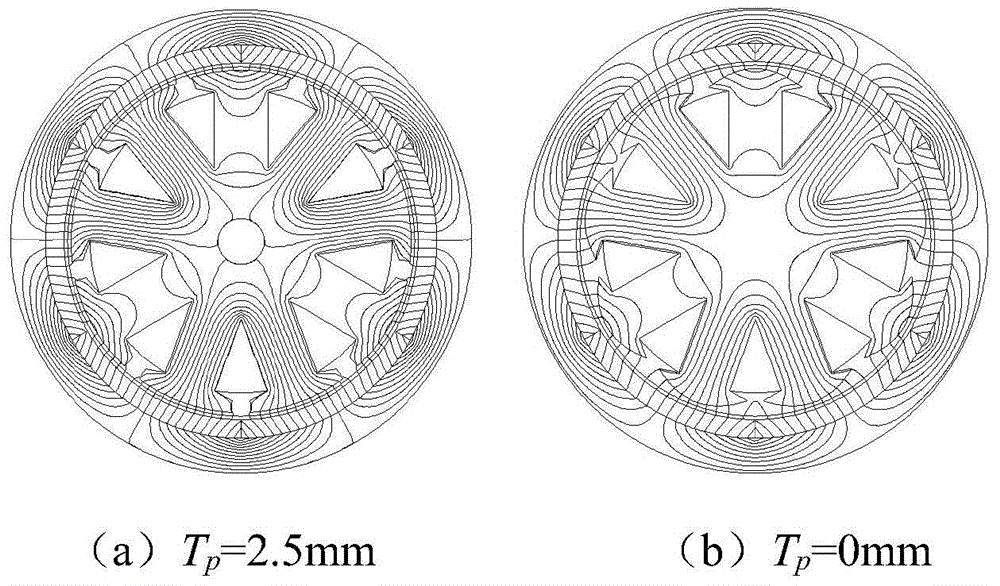

[0056] Step 2. Optimize the shape of the teeth of the permanent magnet motor and change the height of the stator tooth tip, so that the shape of the stator tooth tip changes from a uniform distribution to a symmetrical sinusoidal shape;

[0057] Step 3. Analyze and optimize the pole arc coefficient to weaken the cogging torque;

[0058] Step 4. The magnetic pole shift method is adopted to minimize the cogging torque by weakening the specific harmonic order.

[0059] The cogging torque is produced by the interaction bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com