A filter cloth cleaning device for a filter press

A cleaning device and filter press technology, applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of high cleaning vehicle positioning failure rate, reduced work efficiency, and inability to smoothly drain liquid, etc., to save cleaning water Consumption, reduced labor costs, accurate start and stop positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

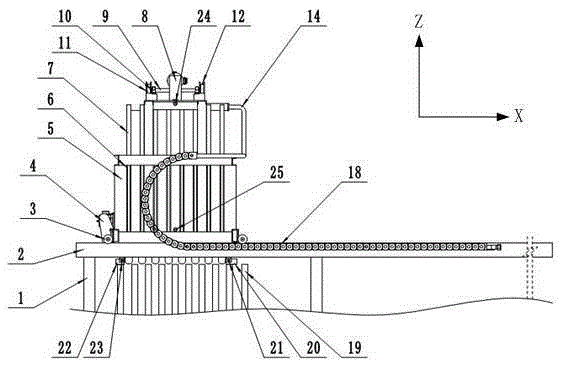

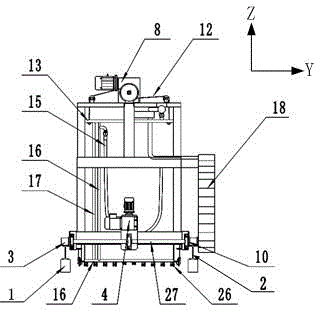

[0015] Embodiment 1, a filter cloth cleaning device for a filter press, comprising a cleaning mobile frame 5, a cleaning lifting frame 7, a detection plate, a position sensor, and a limit switch, is characterized in that:

[0016] The four corners of the bottom of the cleaning mobile frame 5 are provided with rollers 3, and the rollers 3 correspond to the track 2 arranged along the X direction on the filter press frame 1, and a pair of rollers 3 distributed along the Y direction are fixed respectively along the Y direction. Distribute the walking transmission shaft 27; the bottom of the cleaning mobile frame 5 is provided with the walking motor 4 along the Y direction, and the torque of the walking motor is passed to the walking transmission shaft 27 by the speed reducer; the cleaning mobile frame 5 is provided with 8 groups of cleaning pipe guide grooves 6 along the Z direction, , the cleaning pipe guide groove 6 is distributed on both sides of the cleaning mobile frame 5 alon...

Embodiment 2

[0019] Embodiment 2 is the same as Embodiment 1 except that it also includes a drag chain 18 , and the water pipe connected to the buffer water pipe 14 is arranged in the drag chain 18 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com