Automatic adjustment buckwheat husking machine husking gap method and device

A buckwheat hulling machine and automatic adjustment technology, applied in grain husking, grain processing, application, etc., can solve problems such as potential safety hazards, reduce randomness, improve automation level, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

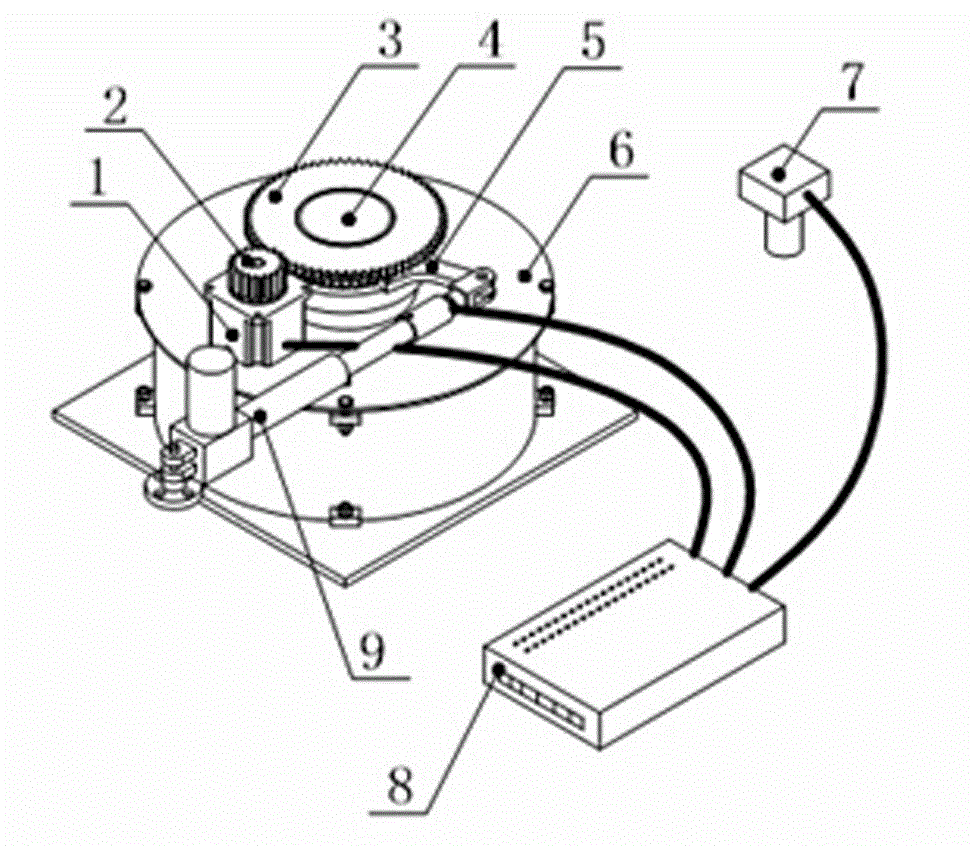

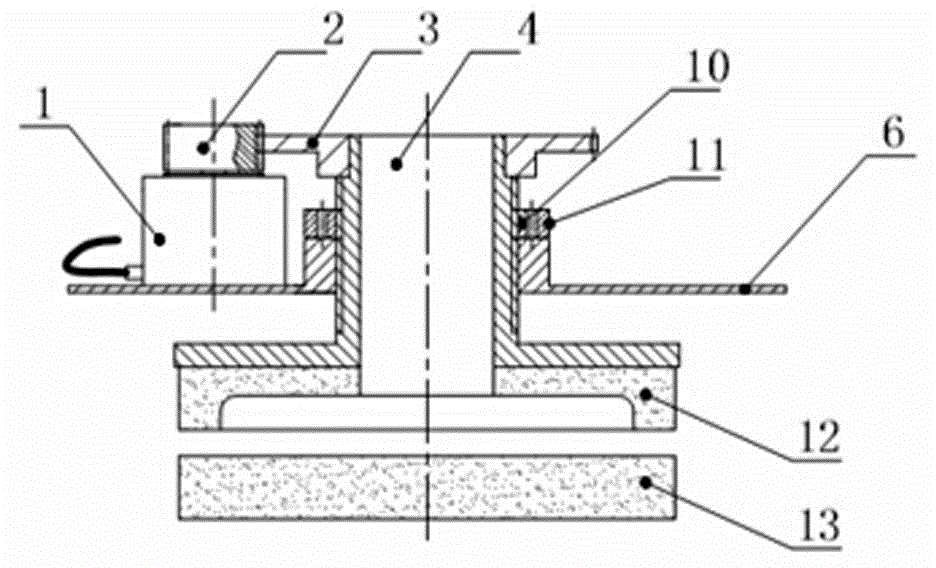

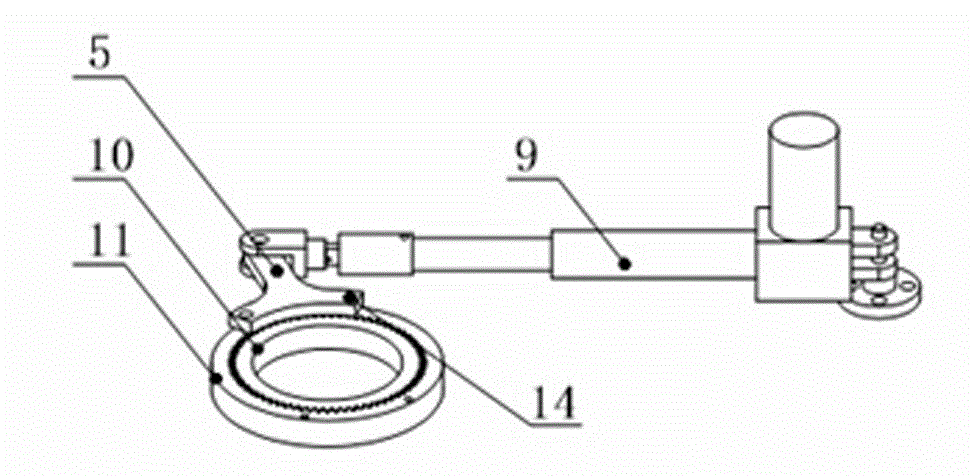

[0014] see Figure 1-Figure 3 , the present invention is a device for automatically adjusting the shelling gap of a buckwheat sheller. The overall structure is mainly composed of a stepping motor (1), a driving gear (2), a driven gear (3), a feeding cylinder (4), and an (5), upper cover of sheller (6), rice output rate image recognition system (7), single-chip microcomputer control system (8), electric push rod (9), locking gear (10), ring gear (11), upper Sand tray (12), lower sand tray (13), screw (14) etc. are formed.

[0015] The upper part of the feeding cylinder (4) is connected to the driven gear (3), and the lower part is connected to the upper sand disc (12). At the same time, the feeding cylinder (4) is connected to the upper cover (6) of the sheller through threads; the upper cover (6) of the sheller Fixed, due to the threaded connection, when the feed cylinder (4) is turned, the feed cylinder (4) and the upper sand table (12) will rise or fall accordingly, that is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com