Mold plate lifting structure of core shooter

A lifting structure and core shooting machine technology, applied in the field of sand molding production, can solve problems such as easy vibration, affecting equipment life, machine damage, etc., to achieve the effect of ensuring service life, ensuring stable lifting, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

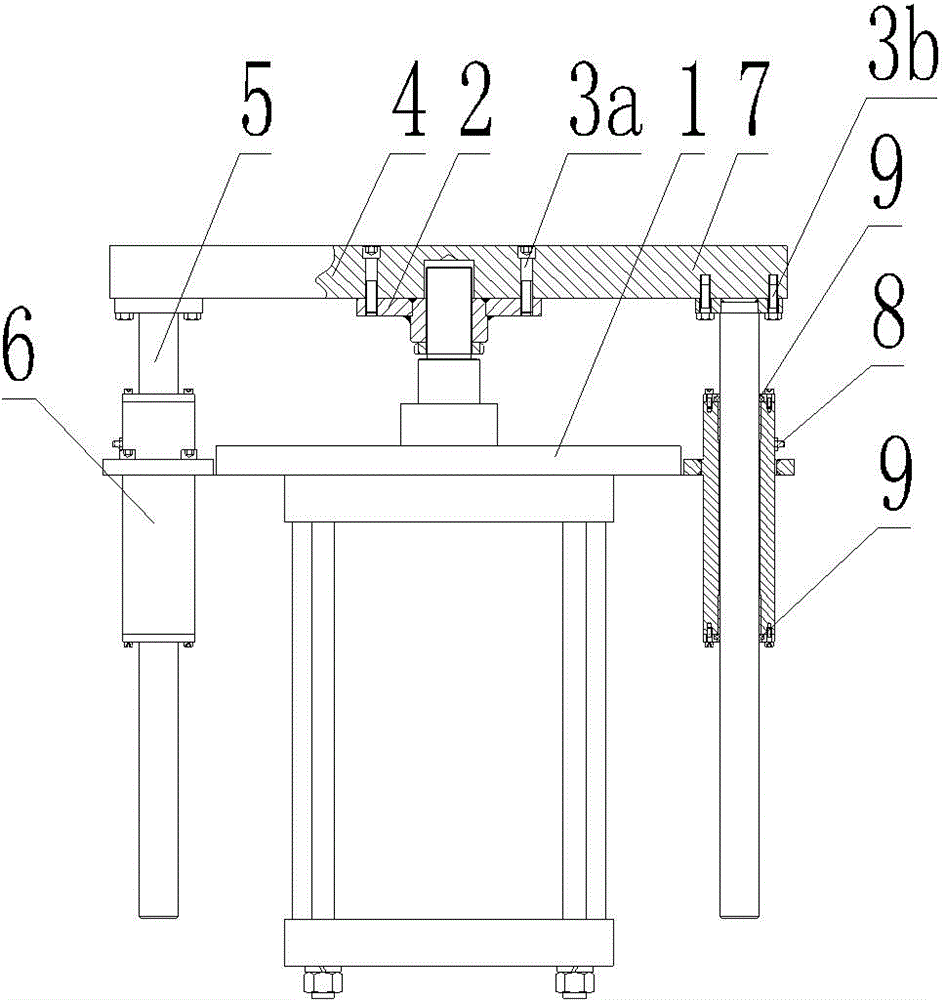

[0012] See figure 1 , the present invention includes a cylinder 1, the joint 2 of the cylinder 1 is fixedly connected to the template 4 by bolts 3a, guide posts 5 are respectively arranged on both sides of the cylinder 1, the guide posts 5 are set in the sliding sleeve 6, and the top of the guide post 4 passes through the bolts 3b It is fixedly connected with the lower surface of the template 7 , the side wall of the sliding sleeve 6 is provided with a straight-through pressure oiling cup 8 , and the two ends of the sliding sleeve 6 are respectively provided with J-shaped dust-proof rings 9 .

[0013] After the mold is placed on the formwork, the cylinder 1 pushes the formwork to move up and down to cooperate with the shooter of the core shooter. There are guide posts 5 and sliding sleeves 6 on both sides of the cylinder 1 to ensure the steady rise and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com