Method for welding roller for towing engine

A welding method and towing cable technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of increasing safety hazards, not having ribs, and cable wear, etc., to reduce wear, control welding deformation, and implement simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

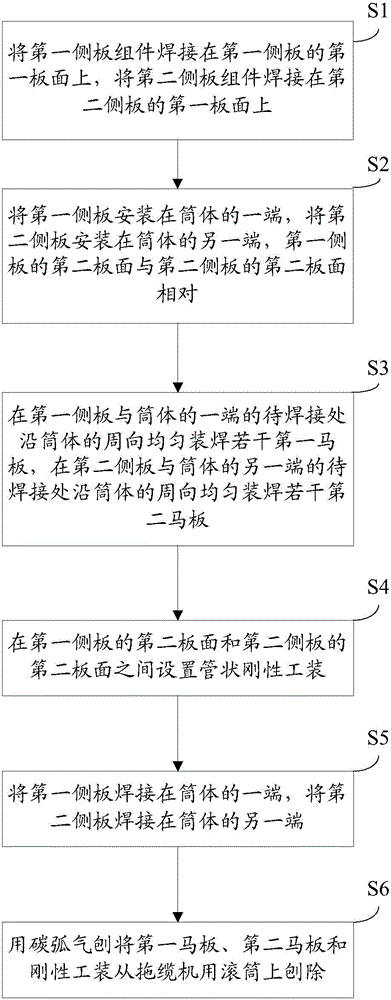

[0028] The embodiment of the present invention provides a welding method for a drum for a towing machine, which is especially suitable for a 250T towing machine (the outer diameter of the side plate of the drum for a 250T towing machine reaches 2700mm), see figure 1 , the welding method includes:

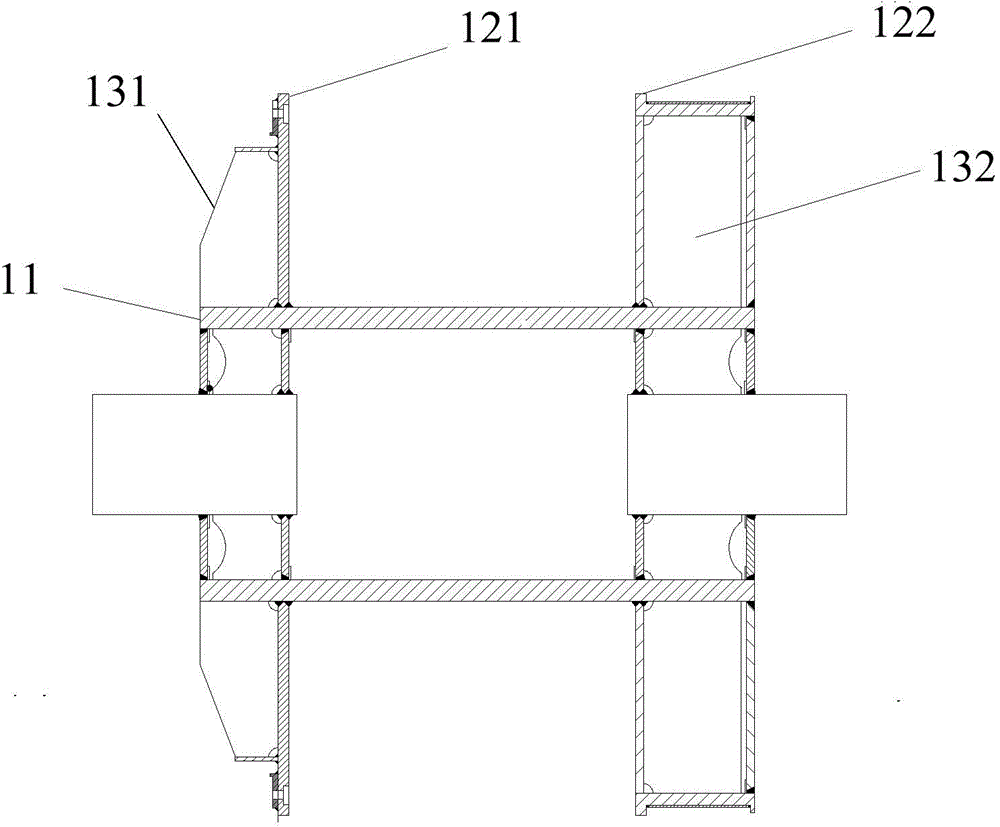

[0029] Step S1 : welding the first side plate assembly 131 on the first surface of the first side plate 121 , and welding the second side plate assembly 132 on the first surface of the second side plate 122 .

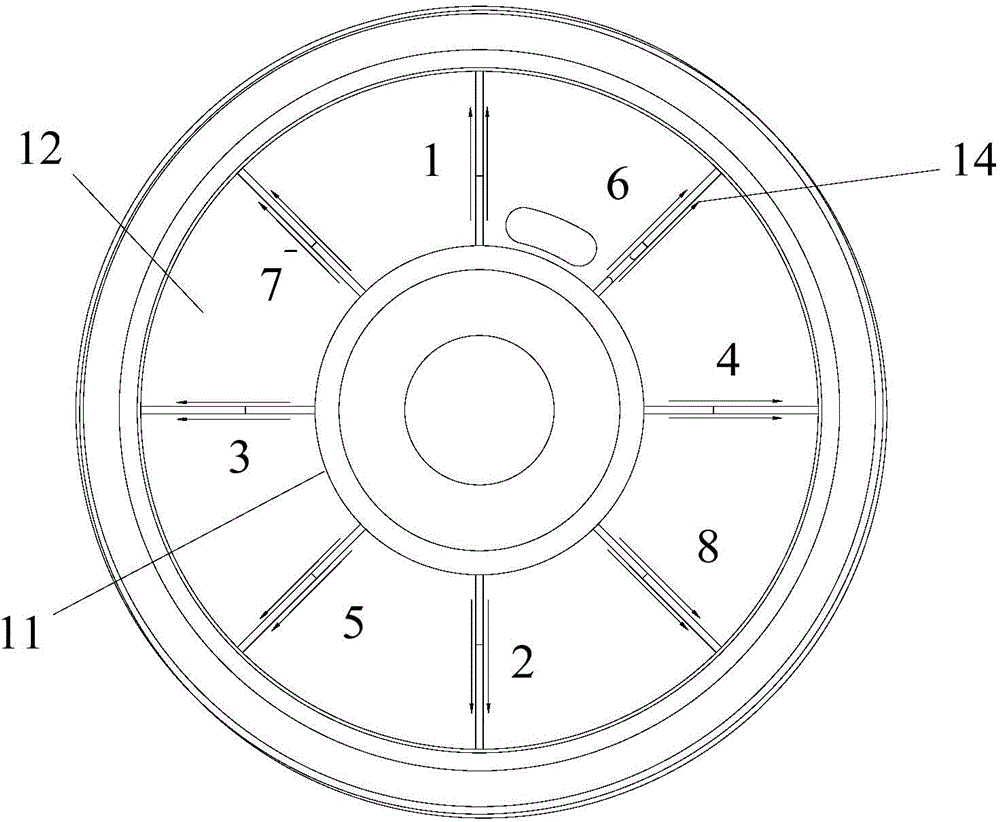

[0030] see figure 2 , The drum for the towing machine includes a cylinder body 11 , a first side plate 121 , a second side plate 122 , a first side plate assembly 131 and a second side plate assembly 132 . The first side plate 121 is welded on one end of the barrel 11 , and the second side plate 122 is welded on the other end of the barrel 11 . The first side plate assembly 131 is welded on the first surface of the first side plate 121 , and the second side plate assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com