Reversing radar punching equipment special for automobile rear bumper

A reversing radar and bumper technology, applied in metal processing and other directions, can solve the problems of difficulty in improving product productivity, lack of rear bumper reversing radar installation holes, affecting product surface quality, etc., to improve production efficiency, equipment structure is reasonable and beautiful, Place easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

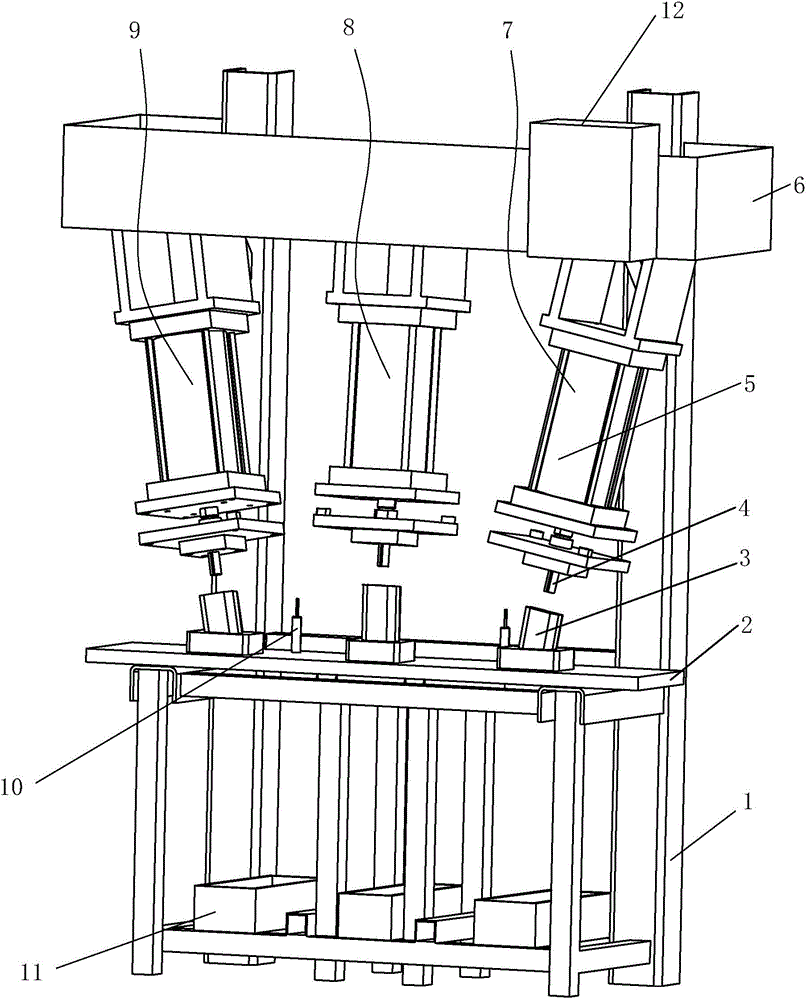

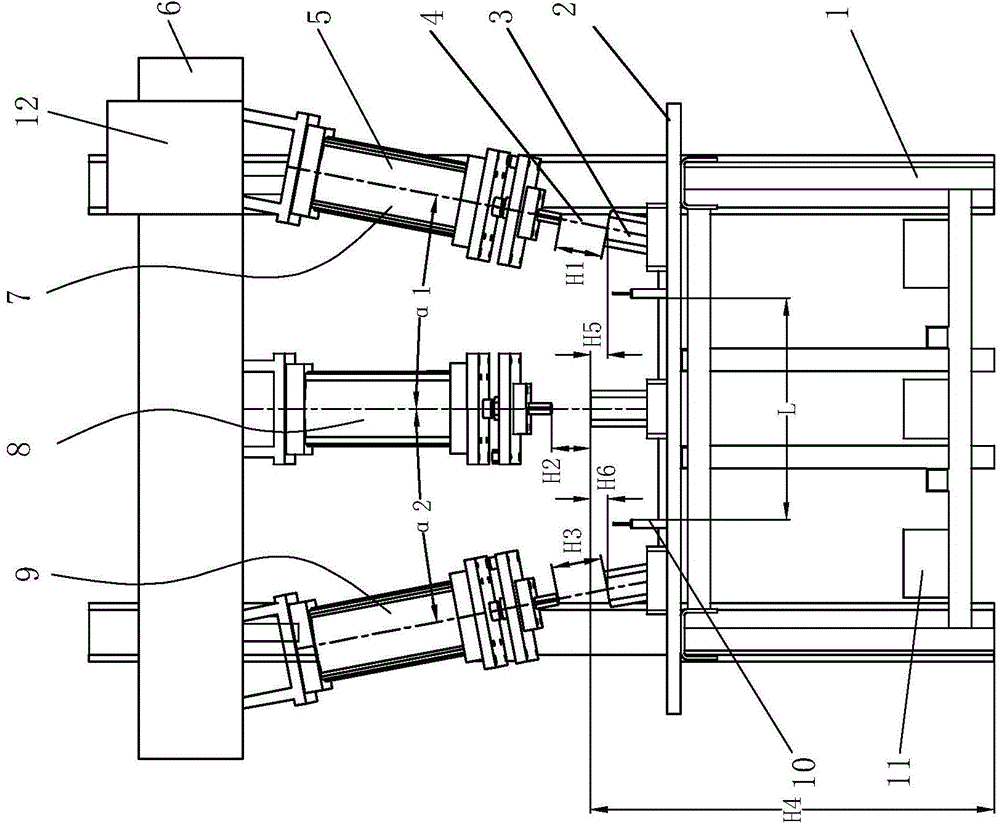

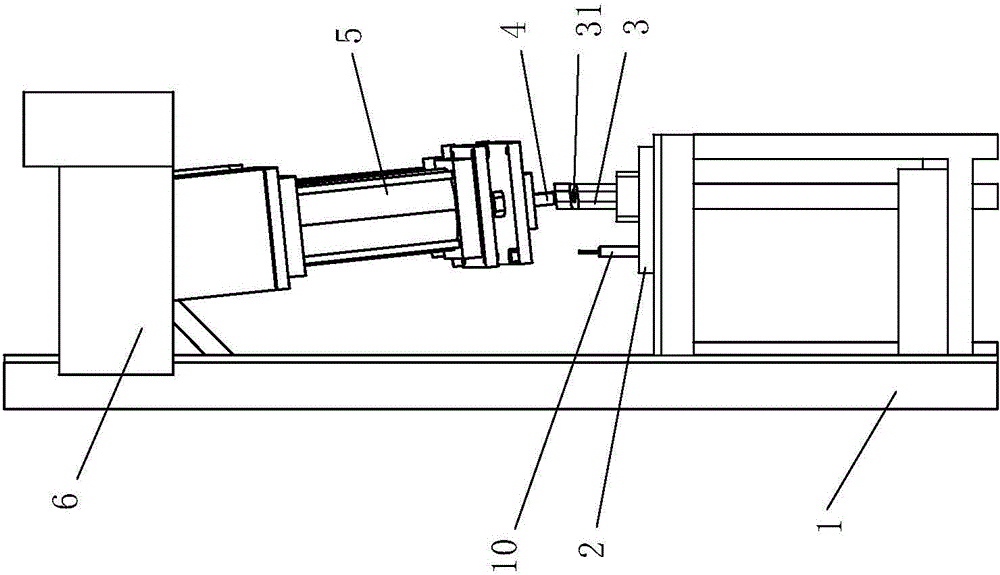

[0026] Embodiment 1: A special reversing radar punching device for the rear bumper of an automobile, such as Figure 1-Figure 3 As shown, it includes a frame 1, a bumper positioning device 10, a punching assembly I7, a punching assembly II8, and a punching assembly III9. The frame is provided with a cylinder mounting plate 6 and a tire mold mounting plate 2 respectively. The punching assembly I, punching assembly II, and punching assembly III described above are all composed of a bumper imitation tire mold 3 installed on the tire mold mounting plate, a stamping cylinder 5 connected to the cylinder mounting plate, and a punching cylinder mounted on the stamping cylinder. The punching knife 4 on the upper part is composed of a punching hole 31 matched with the punching knife in the middle of the bumper profiling tire mold, and the bumper profiling tire mold 3, stamping cylinder 5 and punching of the same group of punching components are The center line of the knife 4 is located o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com