Electronic element pin insulating sleeve sheathing machine

A technology for insulating sleeves and electronic components, applied in auxiliary devices, metal processing, metal processing equipment, etc., can solve problems such as difficult processing, mass production, and implementation, and achieve easy processing, improved labor efficiency and The effect of insulation quality and ease of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

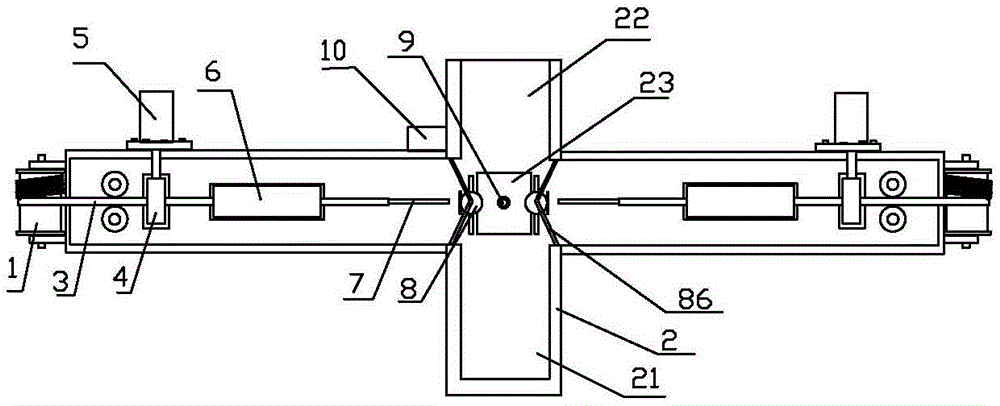

[0027] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 A schematic diagram of the structure of an insulating sleeve fitting machine is given when the left and right sides of an electronic component are a circular pin. refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Make the invention. The electronic component pin insulating sleeve fitting machine includes an insulating sleeve roll 1 and a "ten"-shaped workbench 2, and an insulating sleeve 3 is wound on the insulating sleeve roll 1, which is characterized in that: There are two insulating sleeve rolls 1 on the left and right, which are symmetrically fixed on the outside of the left and right ends of the "ten"-shaped workbench 2 through brackets; Tube conveying nip roller 4, one end of the shaft of the insulating casing conveying nip roller 4 at the left and right ends is respectively connected with the main shaft of the corresponding micro-stepping motor 5, and the stepping rotation of the two...

Embodiment 2

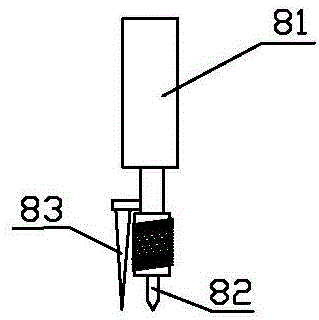

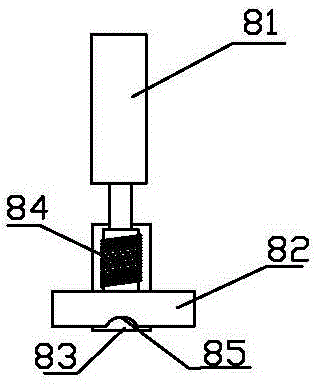

[0038] Image 6 , Figure 7 , Figure 8 The side view of the insulating sleeve cutting device, the axial section of the magnetic sleeve and the suspended iron bar, and the enlarged side view of the insulating sleeve conveying nip roller are given when the left and right sides of an electronic component are multiple flat pins.

[0039] combine figure 1 , figure 2 , when there are multiple flat pins on the left and right sides of the electronic component, the insulating sleeve cutting device, the magnetic sleeve and the suspended iron bar and the insulating sleeve conveying nip roller are as follows: Image 6 , Figure 7 , Figure 8 shown. Image 6 The center cut arc opening 85 is a partial opening, and the width of the flat opening is consistent with the width of multiple flat pins of the electronic component; the axial section of the magnetic sleeve and the suspension iron bar is as follows: Figure 7 As shown, the magnetic sleeve 6 and the suspension iron bar 7 are fl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap