Mechanism for adjusting height of automobile glass in film plating process

An automotive glass, highly advanced technology, used in conveyor objects, furnaces, lighting and heating equipment, etc., to solve problems such as troublesome coating processing operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

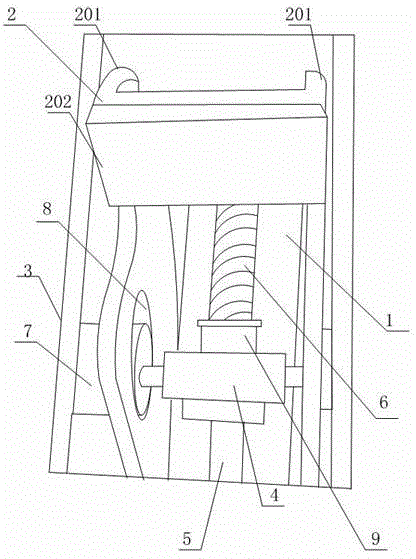

[0018] Such as figure 1 and figure 2 As shown, the mechanism for adjusting the height of the automobile glass during coating is arranged inside the transfer table 3 of the coating transfer mechanism, including the movable part 2, the fixed part 1 and the control handle 10 arranged on the short side outside of the transfer table, and the fixed part 1 is fixed on In the groove of the transfer table 3, the movable part 2 is composed of two reverse S-shaped blocks 201 perpendicular to the horizontal direction and a push block 202 connected to the upper end of the reverse S-shaped block. In contact with the outside of the T-shaped cross of the fixed part 1, the lower end of the reverse S-shaped block 201 has a circular hole 8, and the transfer table 3 is provided with a rotatable cylindrical wheel 7 passing through the circular hole 8 and smaller in diameter than the circular hole 8. Along the direction of the horizontal central axis of the column wheel 7, a connecting rod 4 is p...

Embodiment 2

[0021] Such as figure 1 As shown, the above-mentioned fixing member 1 is T-shaped, and the lateral side of the T-shape is parallel to the short side of the transfer platform 3 . The fixing part is arranged in a T shape, and the lateral side of the T shape can be well fixed inside the transfer table, which can save the space in the tank.

[0022] The above-mentioned elastic member 6 is a spring, and both ends of the spring are provided with pressing blocks 9 . The pressing block can make the pressing force between the connecting rod and the spring more firm.

[0023] The above-mentioned push block 202 is also provided with a plastic glass contact block. The material of the glass determines that the material in contact with it should not be too hard, otherwise the glass is easy to scratch or even break.

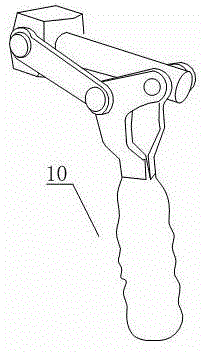

[0024] The control handle 10 includes a handle and a connecting piece, and the handle and the connecting piece are hinged together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com