Laminated forming method of rare-earth ion-doped yttrium aluminum garnet laser ceramics

A technology of yttrium aluminum garnet and laser ceramics, applied in the field of laser materials, can solve the problems of limiting the average power and beam quality of lasers, unfavorable preparation of ceramics for solid-state lasers, single doping concentration, etc., so as to optimize output beam quality and improve ceramics. Optical properties, effects of enhancing optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

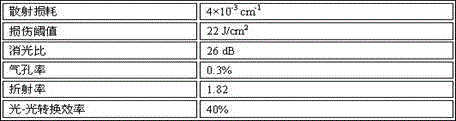

[0023] Test items:

[0024] 1. Scattering loss, damage threshold and extinction ratio are important parameters reflecting the optical characteristics of laser ceramics. If the scattering loss of laser ceramics is low, the damage threshold is high, and the extinction ratio is large, the optical characteristics of laser ceramics are excellent. In order to study the effect of concentration gradient on the optical properties of laser ceramics, we tested the parameters of laser ceramics such as scattering loss, damage threshold and extinction ratio.

[0025] 2. Porosity is a key parameter that affects whether the laser ceramic structure is good or not. If the porosity is low, the laser ceramic structure is good. To investigate the effect of layered molding on the structure of laser ceramics, we tested the porosity of laser ceramics.

[0026] 3. The refractive index is an important parameter to explore whether the thermal deformation inside the laser ceramic is severe or not. If th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap