A method and device for removing organic matter in zinc sulfate solution by pressurized atomization

A zinc sulfate solution, pressurized atomization technology, applied in the direction of improving process efficiency, etc., can solve the problems of reduced electrolytic current efficiency, high production costs, and difficult recycling, and achieve reduced production costs, stable quality, and improved decomposition of organic matter The effect of removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

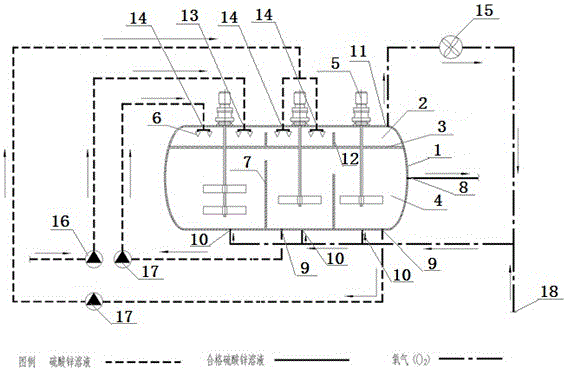

[0031] A method for removing organic matter in a zinc sulfate solution by pressurized atomization, the specific steps are:

[0032] 1) Use a pressurizing device to increase the pressure to 1.0 MPa for the zinc sulfate solution in the hydrometallurgical process with an organic content of 400 mg / L and a pH value of 5.2, and at the same time, use a heating device to increase the temperature of the zinc sulfate solution to 150°C;

[0033] 2) Add the zinc sulfate solution that has been pressurized and heated to a device for removing organic matter in zinc sulfate solution by pressurized atomization. The device for removing organic matter in zinc sulfate solution by pressurized atomization mainly includes pressure Tank body 1, atomization area 2, solution distribution screen 3, stirring area 4, solution mixer 5, atomizer 6, stirring area partition 7, qualified solution outlet 8, circulating liquid outlet 9, circulating gas inlet 10, circulating gas Outlet 11, atomization zone parti...

Embodiment 2

[0041] A method for removing organic matter in a zinc sulfate solution by pressurized atomization, the specific steps are:

[0042] 1) Use a pressurizing device to increase the pressure to 1.2 MPa for the zinc sulfate solution in the hydrometallurgical process with an organic content of 650 mg / L and a pH value of 4.5, and at the same time, use a heating device to increase the temperature of the zinc sulfate solution to 150°C;

[0043] 2) Add the zinc sulfate solution that has been pressurized and heated to a device for removing organic matter in zinc sulfate solution by pressurized atomization, and the device for removing organic matter in zinc sulfate solution by pressurized atomization mainly includes pressure Tank body 1, atomization area 2, solution distribution screen 3, stirring area 4, solution mixer 5, atomizer 6, stirring area partition 7, qualified solution outlet 8, circulating liquid outlet 9, circulating gas inlet 10, circulating gas Outlet 11, atomization zone p...

Embodiment 3

[0051] A method for removing organic matter in a zinc sulfate solution by pressurized atomization, the specific steps are:

[0052] 1) Use a pressurizing device to increase the pressure to 1.5MPa for the zinc sulfate solution in the hydrometallurgical process with an organic content of COD value of 850mg / L and a pH value of 2.6. At the same time, use a heating device to increase the temperature of the zinc sulfate solution to 160°C;

[0053] 2) Add the zinc sulfate solution that has been pressurized and heated to a device for removing organic matter in zinc sulfate solution by pressurized atomization, and the device for removing organic matter in zinc sulfate solution by pressurized atomization mainly includes pressure Tank body 1, atomization area 2, solution distribution screen 3, stirring area 4, solution mixer 5, atomizer 6, stirring area partition 7, qualified solution outlet 8, circulating liquid outlet 9, circulating gas inlet 10, circulating gas Outlet 11, atomization...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com