Single-layer latticed shell steel structure roof system based on concrete building and assembling method of single-layer latticed shell steel structure roof system based on concrete building

A technology for concrete buildings and single-layer reticulated shells, which is applied to the processing of building components, building structures, and building materials, and can solve problems such as difficulties in making and installing steel structures, large-scale steel structure enclosures, and irregular shapes. , to achieve the effect of improving rigidity, simple structure and improving bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

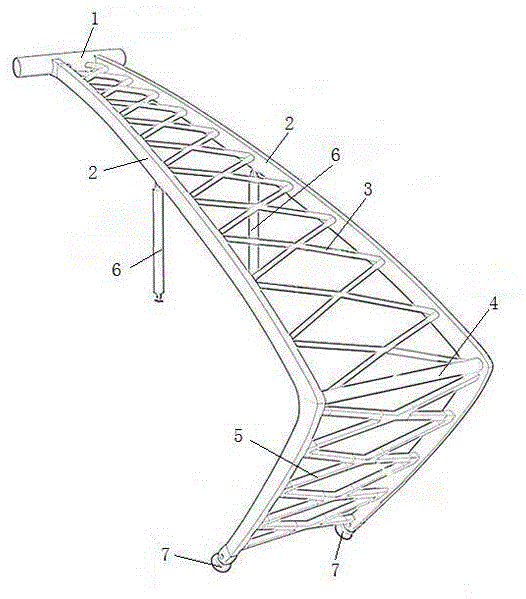

[0027] further Image 6 , Figure 7 and Figure 8 As shown in the figure, the installation of the variable-section box-type support assembly, 1) First, use the temporary support top adjustment device to adjust the inclination angle of the inclined column 2, and use the temporary support for the initial positioning of the inclined column 2. Adjust the oil pump by setting the top of the temporary support , use the oil pump to fine-tune the inclination angle of the inclined column in place, and the temporary support should be stabilized and reinforced by the cable wind rope;

[0028] 2) Then use theodolite and total station to monitor the positioning axis and elevation of the inclined column 2. After adjusting the inclination angle of the inclined column 2, use a temporary horse board to lock it, and then use the theodolite to monitor the axis of the inclined column, and use the total station to monitor the axis of the inclined column. Measure the elevation of the top of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com