Combined jet oil emulsion enveloping type combustor

A combustion chamber and enveloping technology, which is applied in the field of double opposed two-stroke internal combustion engines, can solve the problems affecting the rapid mixing of oil and gas, and the number of injection holes cannot be too many, so as to improve the combustion performance, increase the surrounding space, and increase the utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

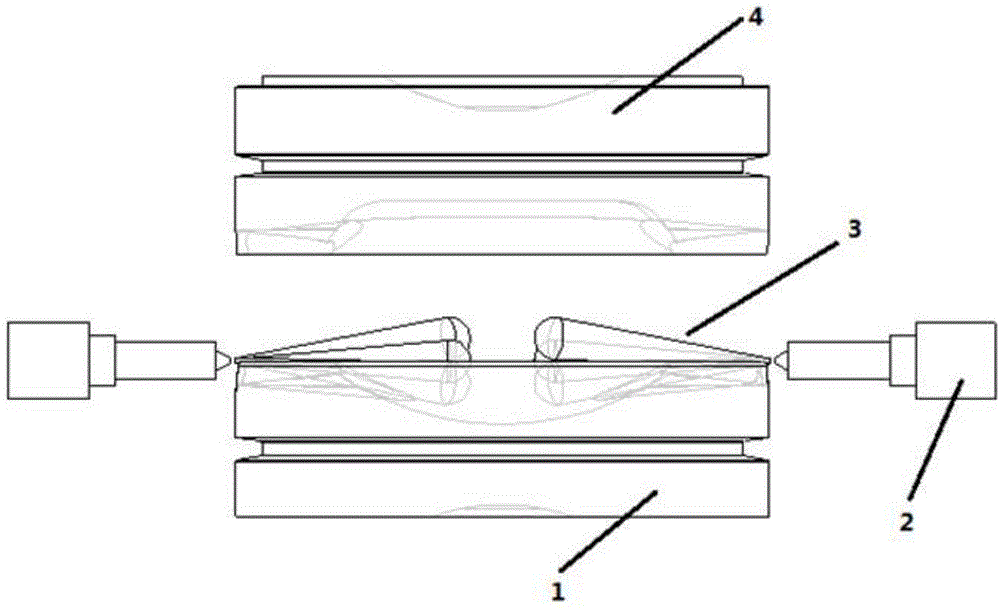

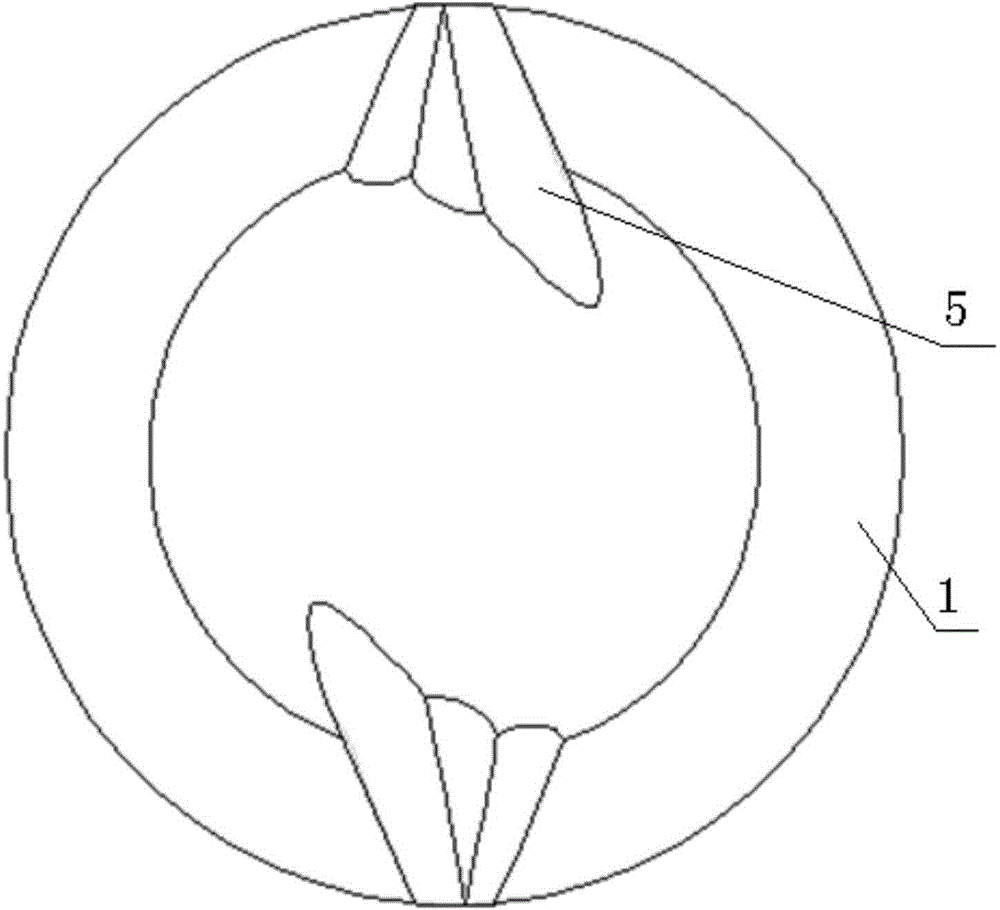

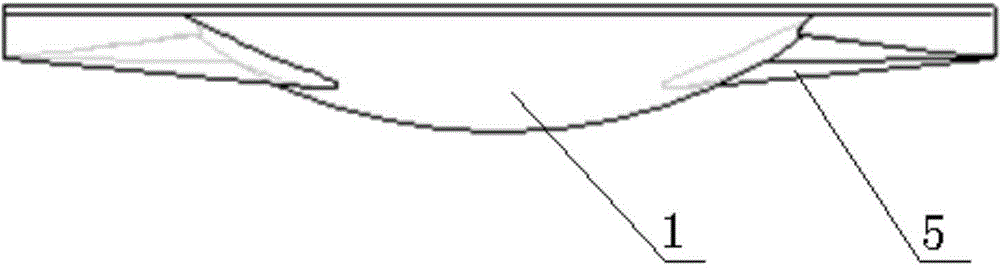

[0020] A combined injection oil beam envelope type combustion chamber described in the present invention, such as Figures 1 to 7 As shown, the combustion chamber 1 on the intake side and the combustion chamber 4 on the exhaust side are included, the shape and structure of the combustion chamber 1 on the intake side is a circular outline, and the structure of the combustion chamber 4 on the exhaust side is an oval outline; The boundary between the intake side combustion chamber 1 and the exhaust side combustion chamber 4 is provided with a guide structure 5 enveloping the oil beam 3 between the adjacent cutouts of the oil nozzle of the fuel injector 2, and the guide structure 5 is based on oil The number of beams and the injection direction are designed into an envelope shape.

[0021] The oppositely arranged fuel injectors 2 inject oil jets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com