Pressure Equalizing Angle Valve for Nitrogen Generator

A technology of bevel valve and valve core, applied in the direction of valve device, valve operation/release device, valve details, etc., can solve the problems of unfavorable adsorption capacity, achieve good regeneration effect, increase overflow speed, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

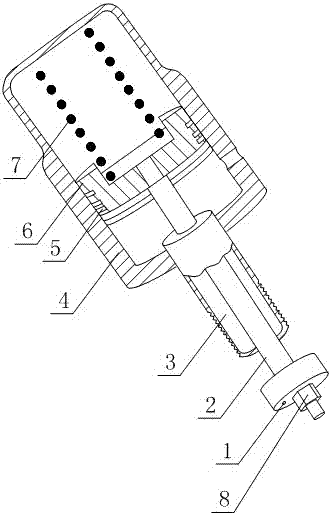

[0023] Such as figure 1 As shown, it includes a valve core 1, a valve stem 2 and a cylinder 4. The cylinder 4 includes a cylinder body, a piston 6 and a return spring 7 arranged in the cylinder body, and the two ends of the valve stem 2 are respectively connected to the valve core 1 and the The piston rod of the cylinder 4 is fixedly connected, and the valve core 1 is provided with through holes running through both ends thereof.

[0024] Specifically, the present invention is arranged on the valve seat of the bevel valve on the pressure equalizing pipe connecting the two adsorption towers. When the bevel valve completes the pressure equalization action and any one of the pressure swing adsorption towers is regenerated, the other is in the working state. The gas in the pressure swing adsorption tower enters the pressure swing adsorption tower under the regeneration state through the set through hole, and the nitrogen content in this part of the gas is at least 99% under normal...

Embodiment 2

[0026] This embodiment is further improved on the basis of embodiment 1, as figure 1 As shown, the cylinder 4 is a horizontal bar single-acting cylinder, and at least three annular sealing rings 5 are provided along the side of the piston 6 .

[0027] In order to reduce the volume of the present invention and simplify the structure of the present invention, the piston rod and the valve rod 2 are integrated.

[0028] It also includes a spool nut 8, the valve stem 2 is in the shape of a stepped shaft with an external thread at one end, the spool 1 is provided with a central hole, the spool 1 is pierced on the valve stem 2, and the spool 1 and The valve stem 2 is fixed by a spool nut 8 .

[0029] The horizontal bar single-acting cylinder has a simple structure and low cost; at least three annular sealing rings 5 are provided to further strengthen the sealing performance of the air intake chamber of the cylinder 4, which is beneficial to ensure the stable operation of the pre...

Embodiment 3

[0032] The present embodiment is further limited on the basis of embodiment 2, as figure 1 As shown, it also includes a cylindrical fixed sleeve 3, one end of the fixed sleeve 3 is fixedly connected to the cylinder body, the other end of the fixed sleeve 3 is provided with external threads, and the center line of the fixed sleeve 3 is in line with the valve stem 2 The center lines are collinear, and the fixed sleeve 3 is located between the valve core 1 and the cylinder body.

[0033] The external thread is a fine pitch thread.

[0034] The fixed sleeve 3 provided is used for the connection of the present invention with the valve seat, that is, the valve seat is provided with an internal thread hole matching the external thread, and the fixed sleeve 3 and the valve seat are threaded to facilitate adjustment of the valve core and the valve seat in the closed state. The compressive stress between the seats ensures the sealing effect when the pressure equalizing tube is disconne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com