Tapered guide cylinder

A technology of guiding cylinders and rotating sleeves, applied in the direction of pipes/pipe joints/pipe fittings, mechanical equipment, pipe components, etc., can solve the problems of unreliable structure, narrow application field, and inapplicable factory transportation guiding function, etc., and achieve simple structure , Reasonable layout, good effect of guiding and transporting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

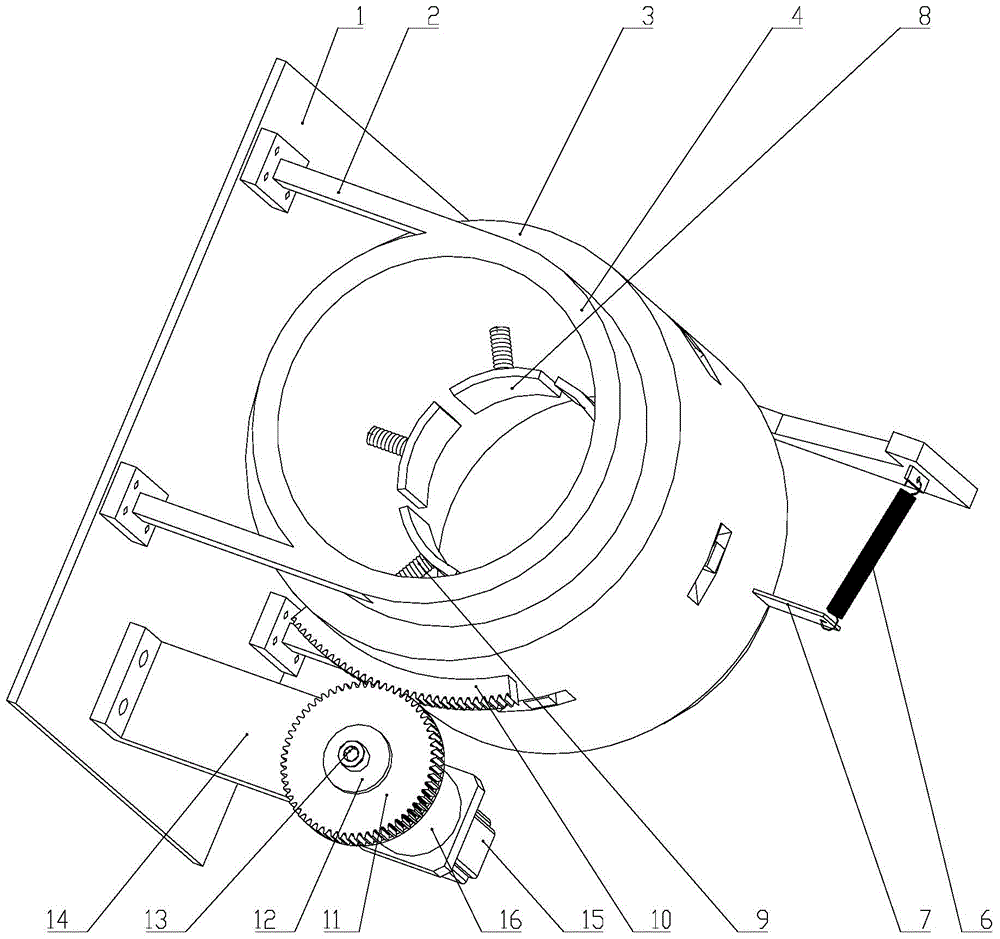

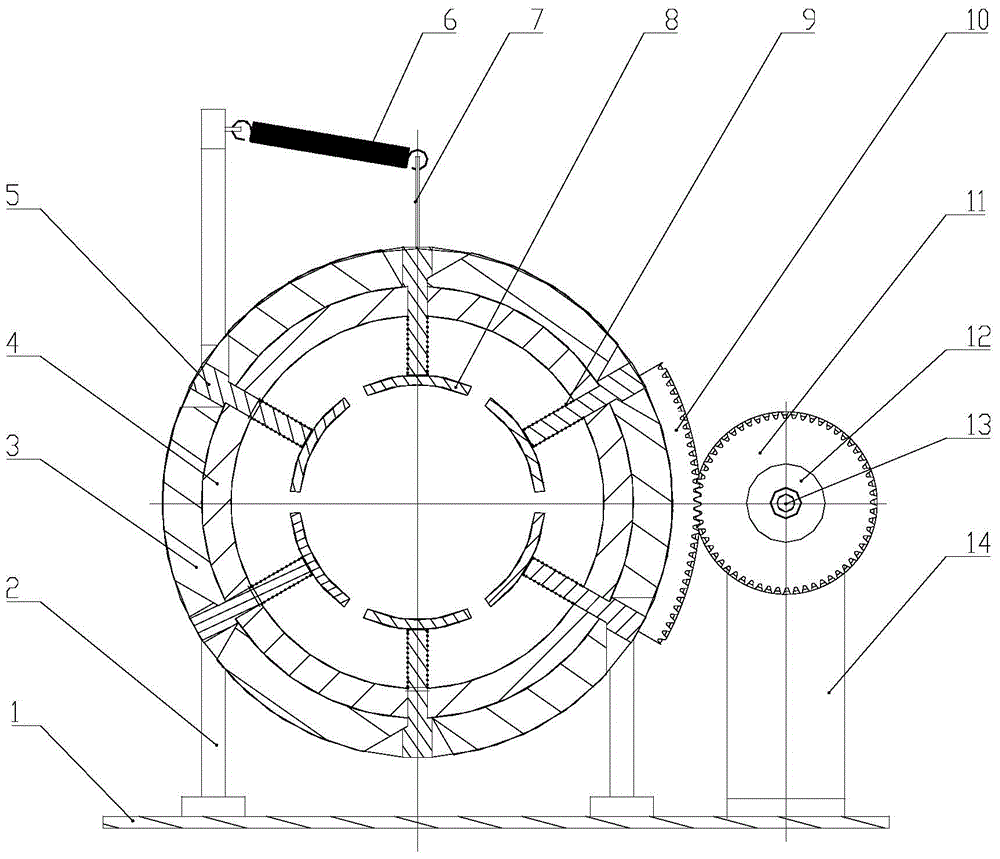

[0011] The present invention is described in more detail below in conjunction with accompanying drawing example:

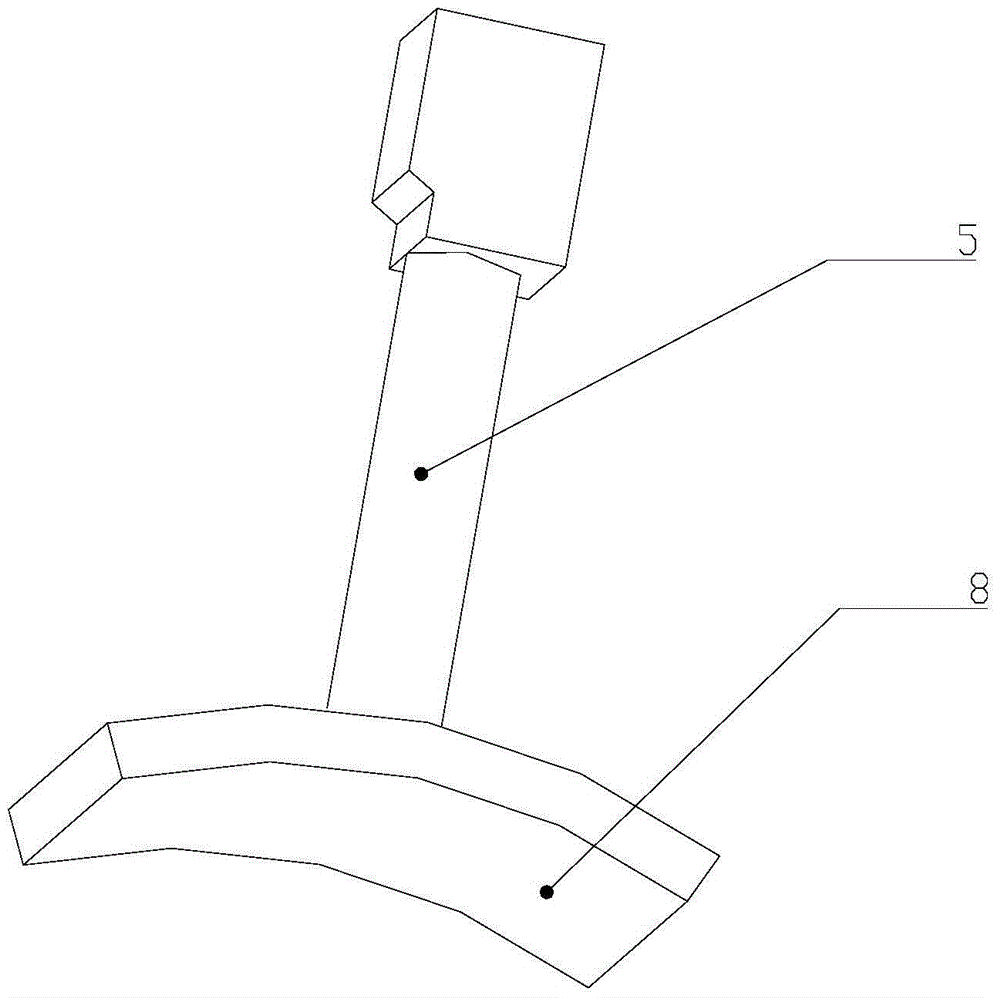

[0012] combine Figure 1~4 , the main components of the present invention are: base 1, support frame 2, rotating sleeve 3, fixed sleeve 4, variable diameter inclined block 5, rotating sleeve return spring 6, spring connecting plate 7, reducing arc plate 8, Arc plate return spring 9, tooth arc 10, gear 11, catch plate 12, screw 13, motor connecting plate 14, motor 15, speed reducer 16.

[0013] In the guide cylinder mechanism, six circular holes are evenly distributed on the fixed sleeve 4, the fixed sleeve 4 is welded to the support frame 2, the support frame 2 is connected to the base 1 through bolts, and six variable holes are evenly distributed on the rotating sleeve 3. The diameter chute corresponds to the round hole on the fixed sleeve 4. The variable diameter slant block 5 and the variable diameter arc plate 8 are welded together. The arc plate return sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com