Method of detecting state of ultrasonic flowmeter

A state detection and flowmeter technology, applied in the direction of measuring flow/mass flow, liquid/fluid solid measurement, measuring devices, etc., can solve the problem that the echo signal cannot be received within a certain period of time, the ultrasonic flowmeter cannot work normally, and the receiving No echo signal and other problems, to achieve the effect of simplifying the inspection and maintenance process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further elaborated below in conjunction with the accompanying drawings.

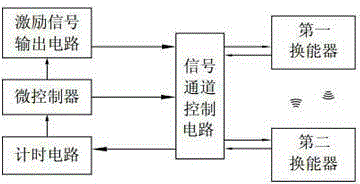

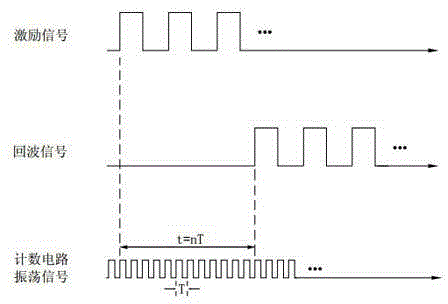

[0014] see figure 1 , At least a microcontroller, a timing circuit, an excitation signal output circuit, a signal channel control circuit, a first transducer and a second transducer are arranged in the detection system of the ultrasonic flowmeter. Among them, the micro-controller is used to systematically control the work of each circuit module in the ultrasonic flowmeter, and the obtained timing data is combined with other factors such as temperature and flow tube section to comprehensively calculate the fluid volume; the excitation signal output circuit is used to output excitation and transmit energy The excitation signal of the transducer; the signal channel control circuit is used to selectively connect the excitation signal to the first transducer / second transducer to achieve the purpose of measuring the forward / countercurrent flow velocity; while the existing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com