A Method for Simulating Spontaneous Combustion of Coal Pile

A technology of coal pile and spontaneous combustion, applied in the direction of thermal development of materials, etc., can solve the problems of inability to simulate temperature and energy point-to-surface contact transfer, difficulty in controlling and simulating oxidation reaction, and inability to simulate oxygen diffusion process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

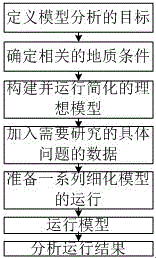

Method used

Image

Examples

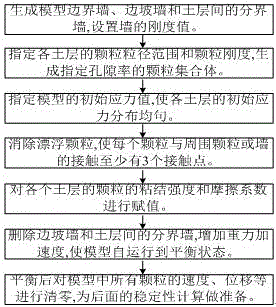

Embodiment Construction

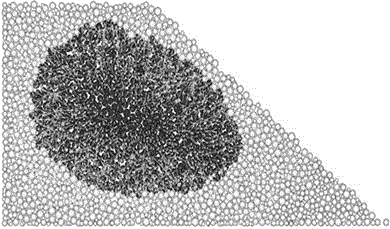

[0031] In order to better explain the construction of coal pile spontaneous combustion model, the working conditions of an example coal pile are explained first. This example is a coal pile in a factory, which needs to use a large amount of coal in the production process, and the coal pile has a large volume. In order to avoid spontaneous combustion accidents that may be caused by long-term stacking of coal piles, our research institute was commissioned by the factory to analyze the spontaneous combustion process of the coal pile and its preventive measures. For this coal pile analysis is especially suitable for PFC3D. According to the information provided by the factory and the relevant parameters obtained from field surveys: the height of the top of the coal pile from the ground (slope height) is 10m, the horizontal length of the top of the pile is 8m, and the horizontal length of the bottom of the pile is 20.5m. Due to hardware limitations and analysis requirements, the wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| shear modulus | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com