Robot fault repairing system and method

A technology of fault repair and robotics, applied in the field of robotics, can solve problems such as judgment and maintenance, and achieve the effects of improving intelligence, reducing the workload of maintenance and after-sales technical support, and achieving good market and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

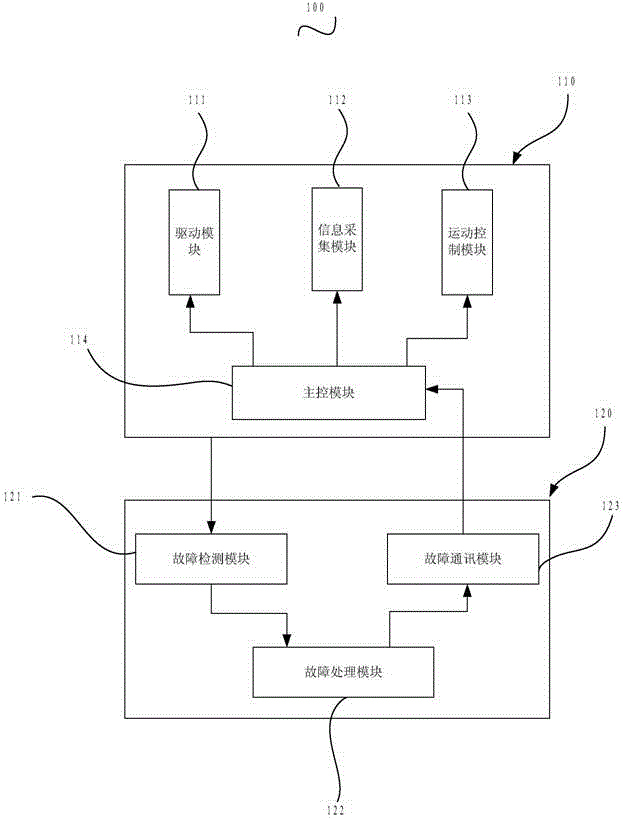

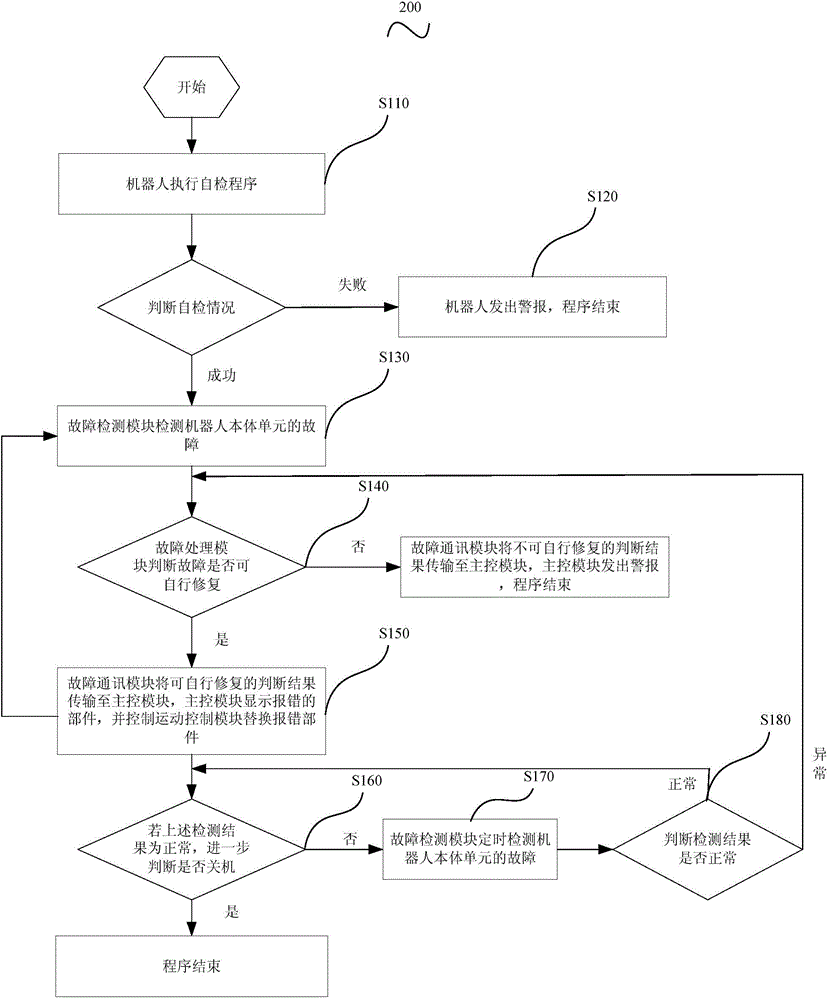

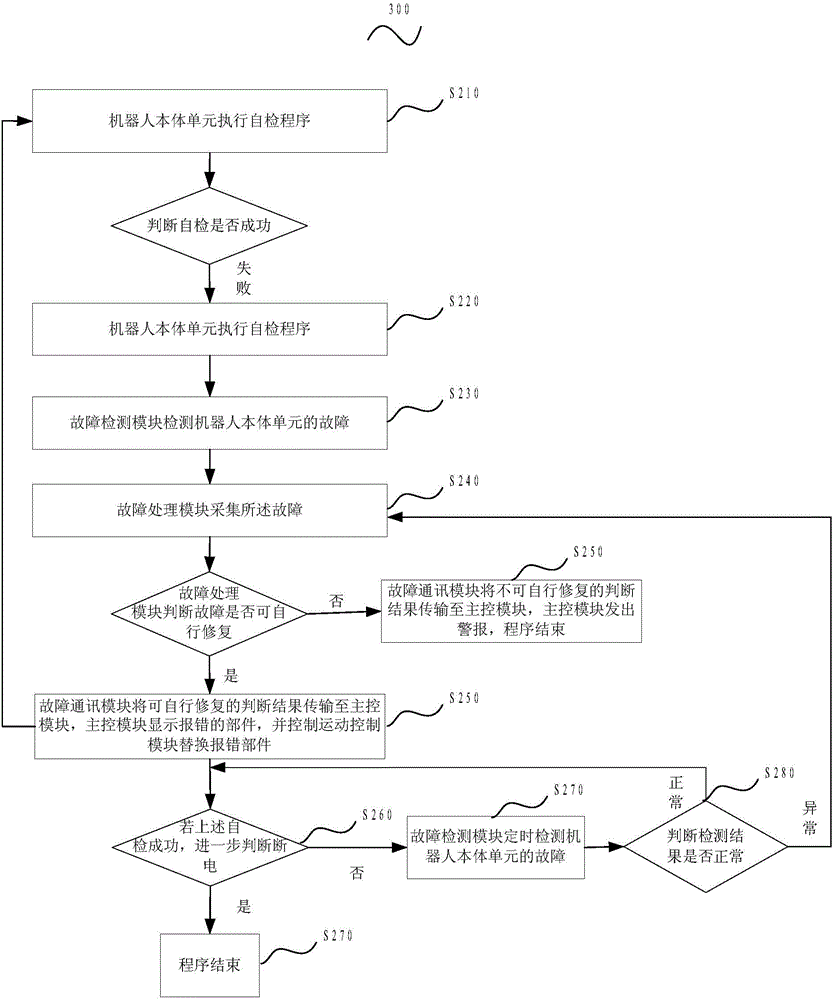

Method used

Image

Examples

Embodiment

[0067] For example, when a fault maintenance function is implemented on a robot body with two 4-DOF arms and an omnidirectional mobile chassis, the following scenarios may occur:

[0068] A failure of a control drive module of the left arm of the robot causes the left arm to fail to move normally, but other parts of the robot can work normally. After adopting the above fault repair method, after the fault detection, analysis and processing unit of the robot detects the fault, it will analyze the fault. , it is considered that the control drive module of the left arm can be replaced by the operation of the right arm. The fault detection analysis processing unit of the robot sends the following operation instructions to the main control module of the robot, and the main control module controls the motion control module of the left arm from the spare part The library finds a new module that is the same as the faulty module of its own, and powers off the faulty board on the left ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com