cooling mechanism

A cooling mechanism and cooling chamber technology, applied in the manufacture of electrical components, circuits, semiconductor/solid-state devices, etc., can solve the problems of chip contact and insufficient spacing, and achieve the effect of reducing cooling air, cost and environmental load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

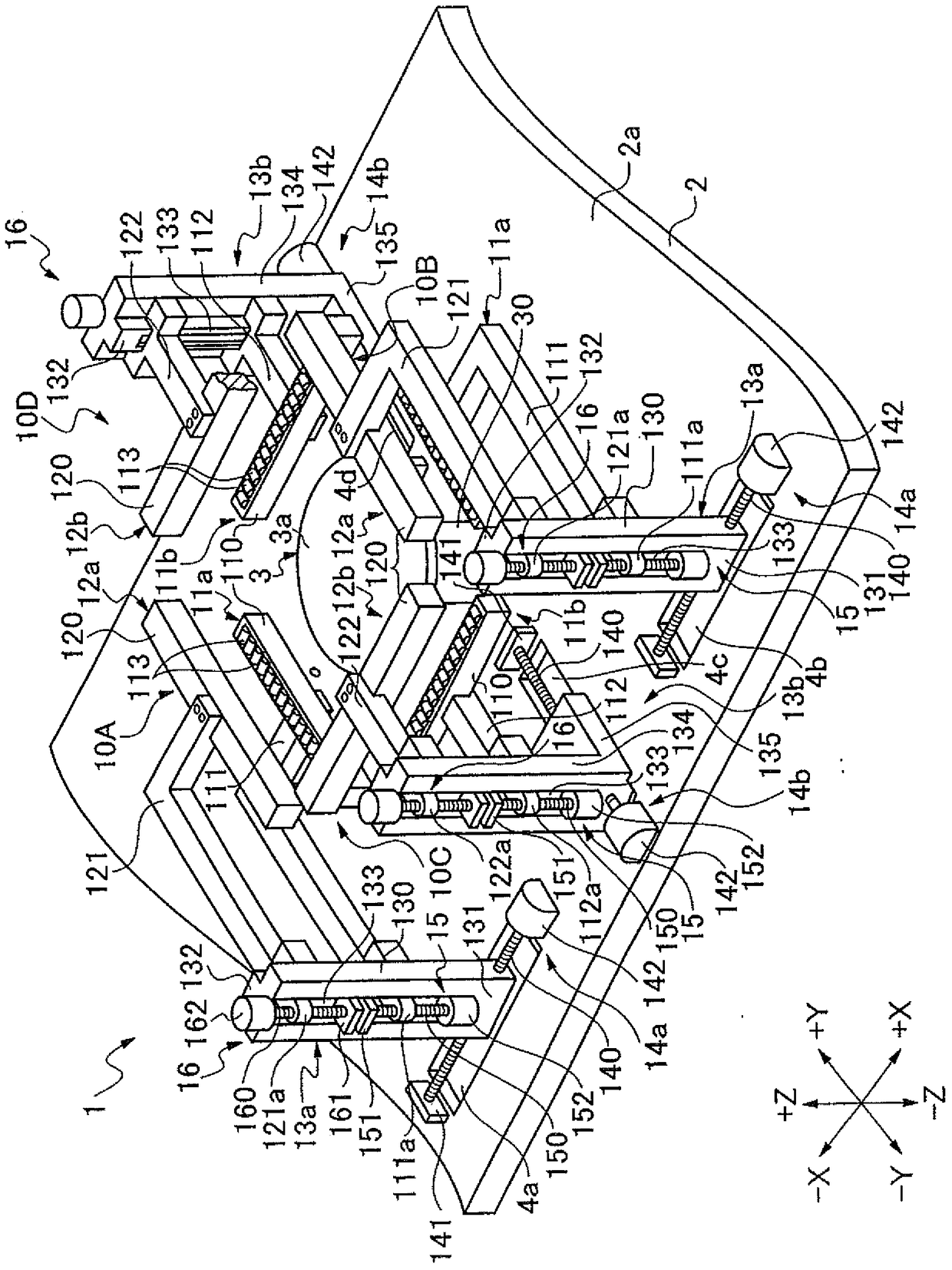

[0113] 1. Structure of the expansion device

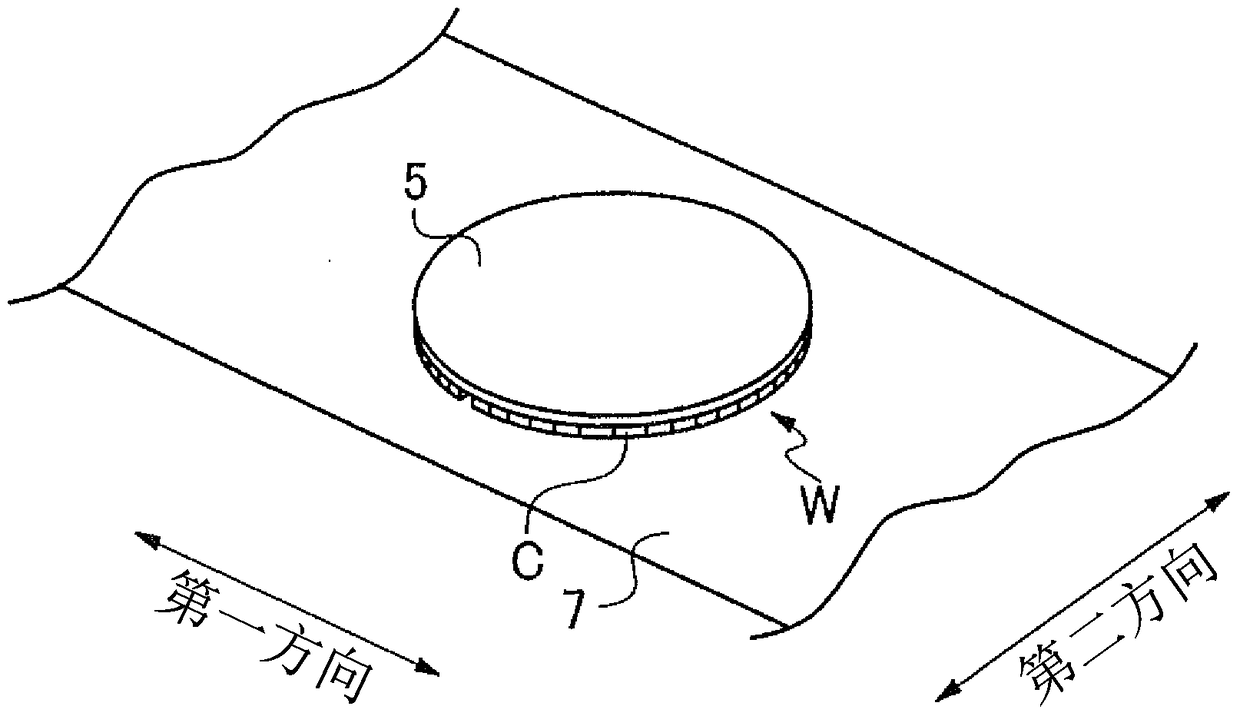

[0114] figure 1 The shown expansion device 1 is, for example, capable of figure 2 The illustrated example of an expansion device that expands the expansion sheet 7 on which the workpiece W is pasted is expanded. The expansion device 1 has a device base 2 , and a holding table 3 is supported up and down at the center of an upper surface 2 a of the device base 2 via a table support 30 . The holding table 3 holds a workpiece W via an expansion sheet 7 . The upper surface of the holding table 3 serves as a holding surface 3a on which the workpiece W is held.

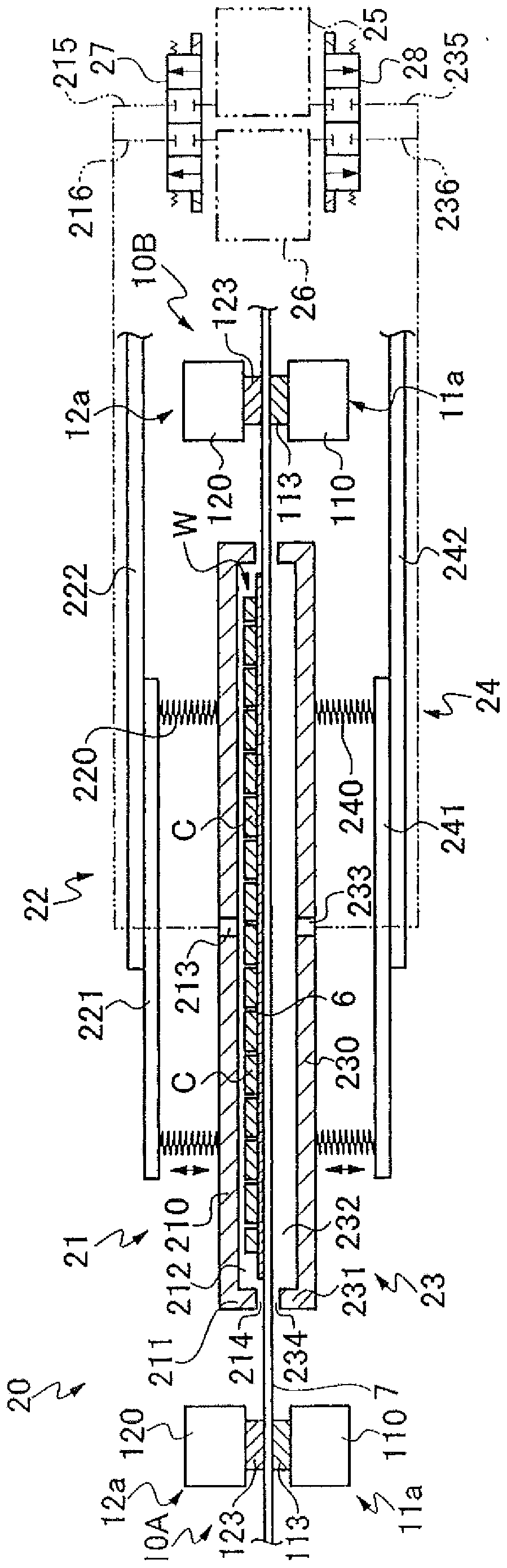

[0115] On the upper surface 2a of the device base 2, a first clamping member 10A and a second clamping member 10B are arranged to face each other across the holding table 3 in the first direction. The first clamping member 10A and the second clamping member 10A Two clamping members 10B enable figure 2 The expansion sheet 7 shown expands in the ±X direction (first direction)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com