Processing program for automatic switching experiment device of capacitor compensation cabinet

A capacitor compensation cabinet, automatic switching technology, applied in the field of electromechanical manufacturing, can solve the problems of inconvenient operation and wiring, increase test cost, increase power loss, etc., achieve convenient wiring, reduce purchase and maintenance costs, and reduce active power The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

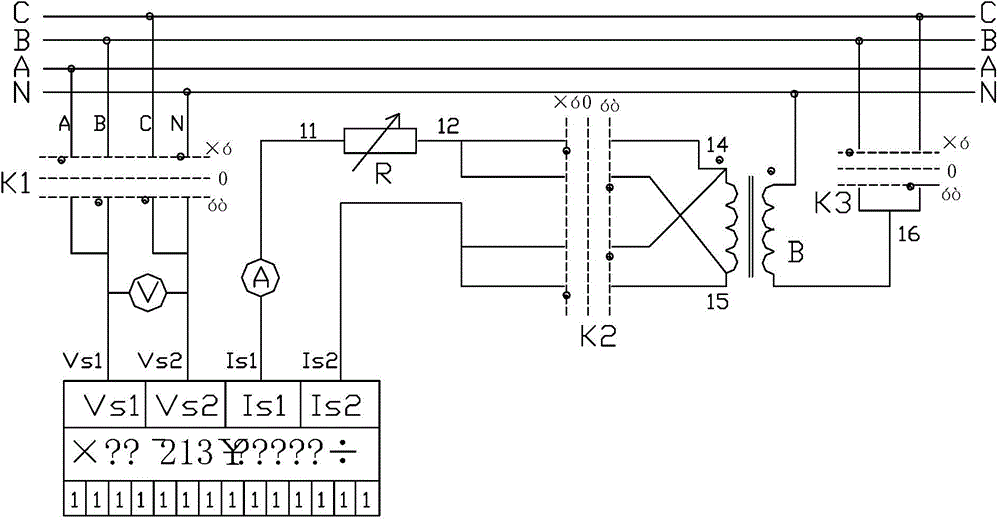

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0012] The invention aims at the defects of the prior art, and adopts the phase difference of the three-phase power supply to change the lead and lag of the power factor during the switching process of the capacitor, so that the capacitor can be switched automatically.

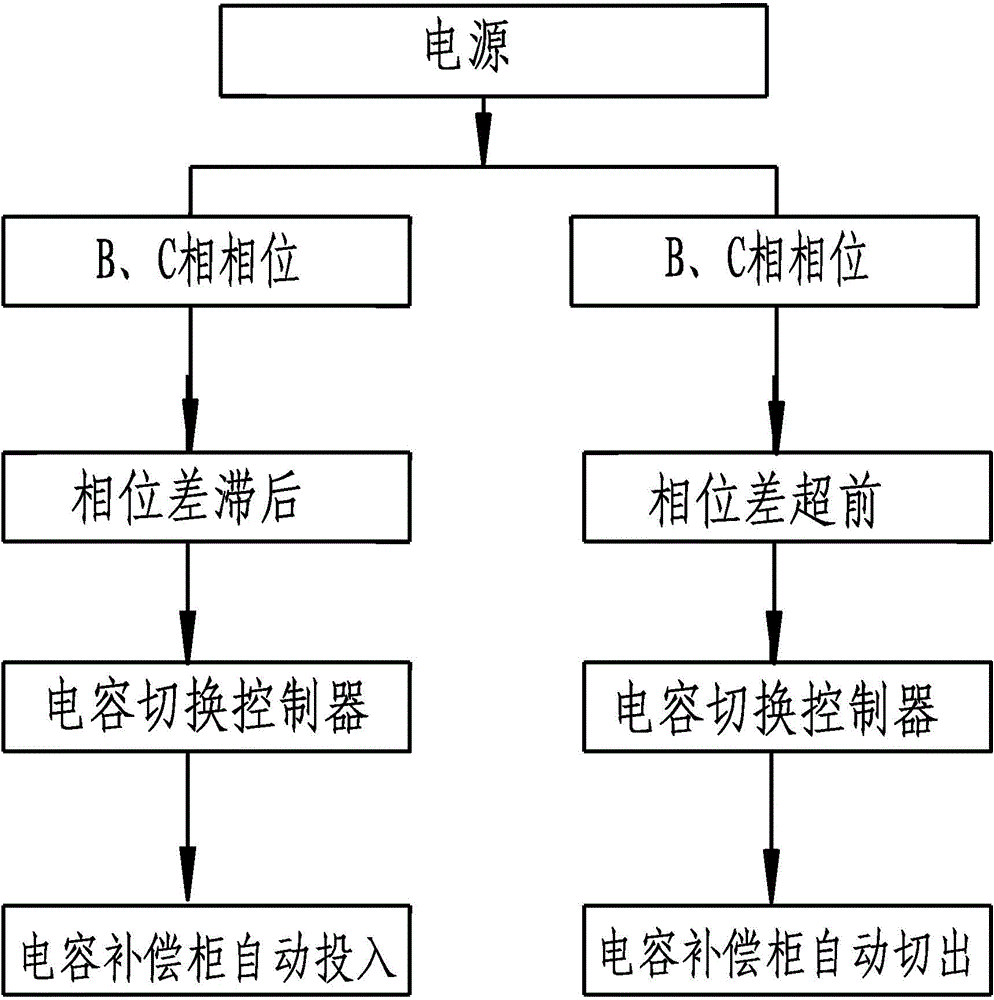

[0013] Such as figure 1 , figure 2 As shown, a processing program of the automatic switching test device of the capacitance compensation cabinet, the processing program takes B-phase and C-phase power respectively, and utilizes that the phase angle difference between the two phases is 120 0 ;Take the phase angle lag of B phase and C phase, switch the zero potential of the automatic switching test device of the capacitor compensation cabinet, and input the capacitor switching controller, so that the capacitor compensation cabinet can be automatically input; take the lead of the phase angle of B ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com