Hydraulic energy saving device of oil pumping unit

An energy-saving device and pumping unit technology, applied in fluid pressure actuation devices, mechanical equipment, actuator accumulators, etc., can solve the problems of high peak power of motors and reverse power generation, and can not achieve energy-saving effects, etc., to ensure The effect of long-term normal operation, lower purchase cost, and reduced torque fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

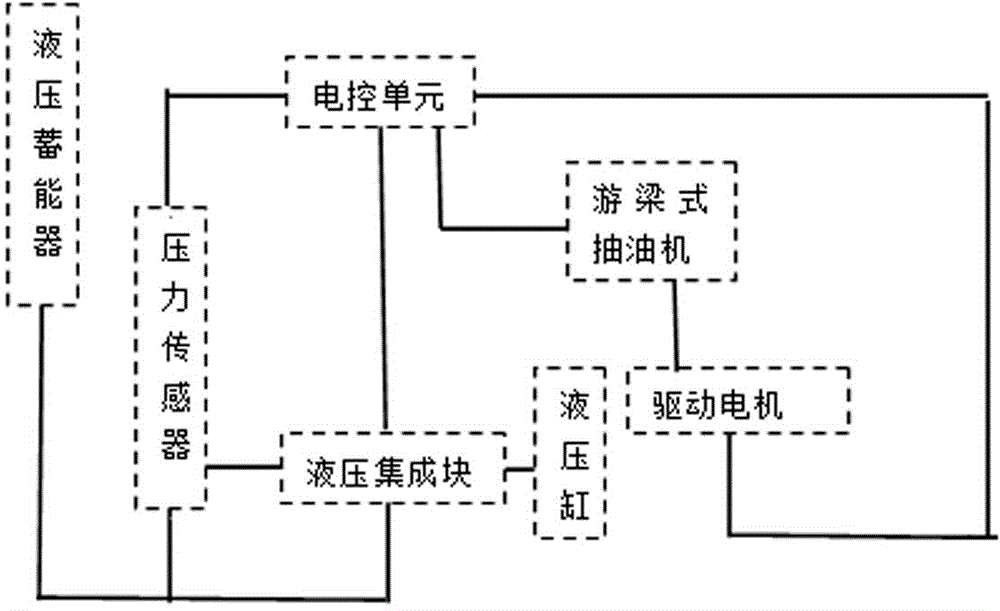

[0015] A hydraulic energy-saving device for a pumping unit is composed of two parts: a mechanical hydraulic assembly and an electric control unit. Wherein, the mechanical hydraulic assembly is composed of a hydraulic cylinder, a hydraulic accumulator, a pressure sensor and a hydraulic integrated block, and the hydraulic accumulator is connected to the pressure sensor and the hydraulic integrated block respectively; the pressure sensor and the hydraulic integrated block are connected to the electronic control unit . The electric control unit is composed of a DSP micro-processing chip, a data acquisition circuit and a control circuit, and the electric control unit is also connected to a hydraulic cylinder. The upper hinge seat of the piston rod of the hydraulic cylinder can be connected with the beam of the external equipment pumping unit and installed at the front end of the pumping unit.

[0016] The hydraulic energy-saving device is connected with the pumping unit beam throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com