The control mechanism of the skin residue separator after processing tomato paste

A technology of separation and control mechanism of skin and slag, which is applied in the separation method, sedimentation separation, and sediment separation by centrifugal force, etc., can solve the problems such as the inability to settle the sloping plate spacing and the adjustable angle of inclination, etc., so as to improve the separation rate and separation of skin and slag. Clarity, reduced overflow loss, accelerated sedimentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

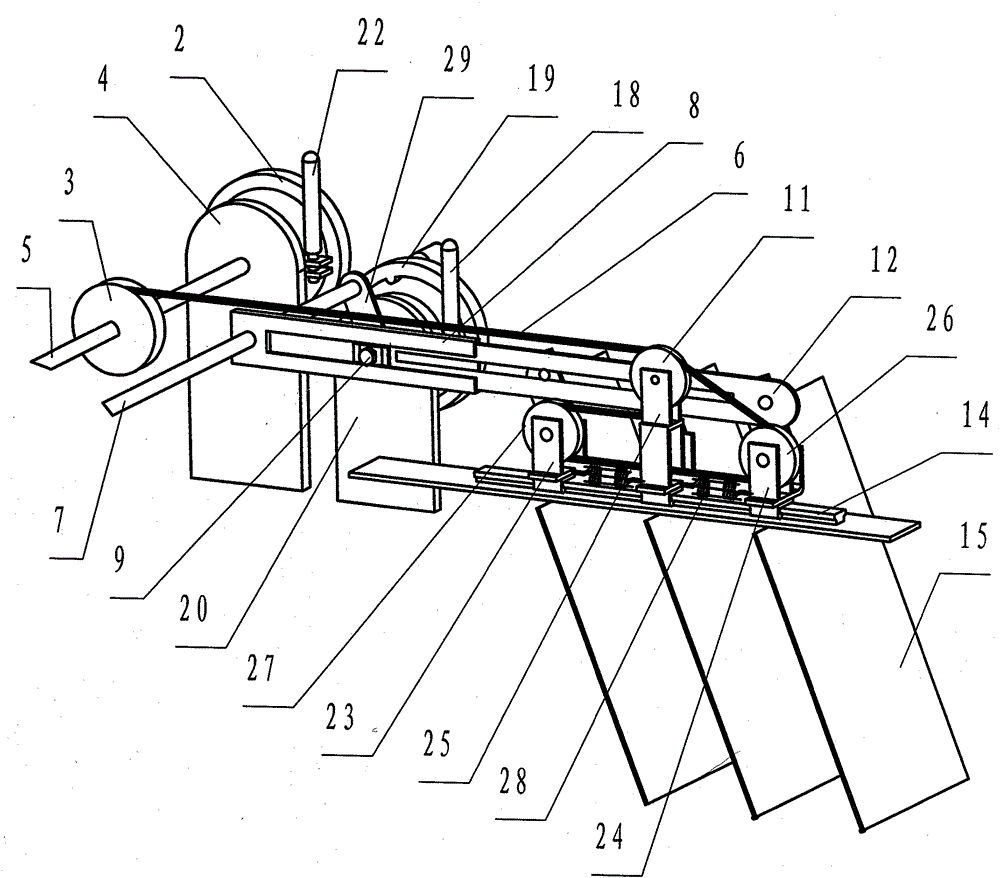

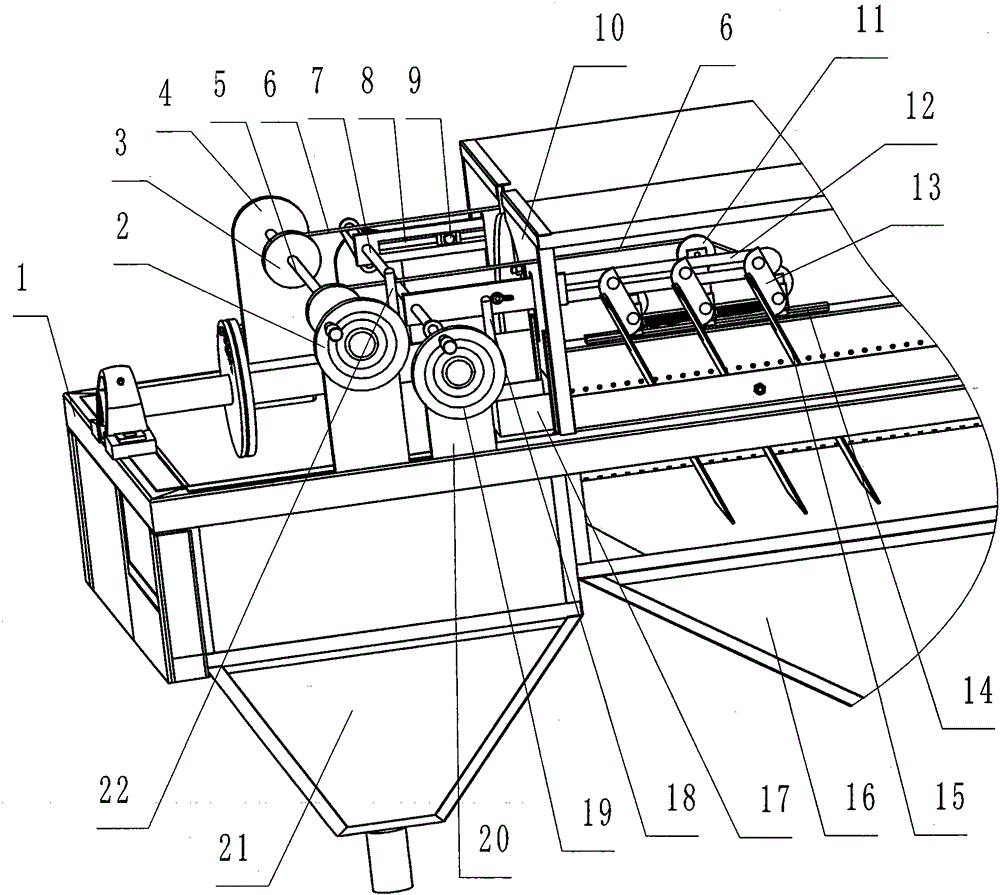

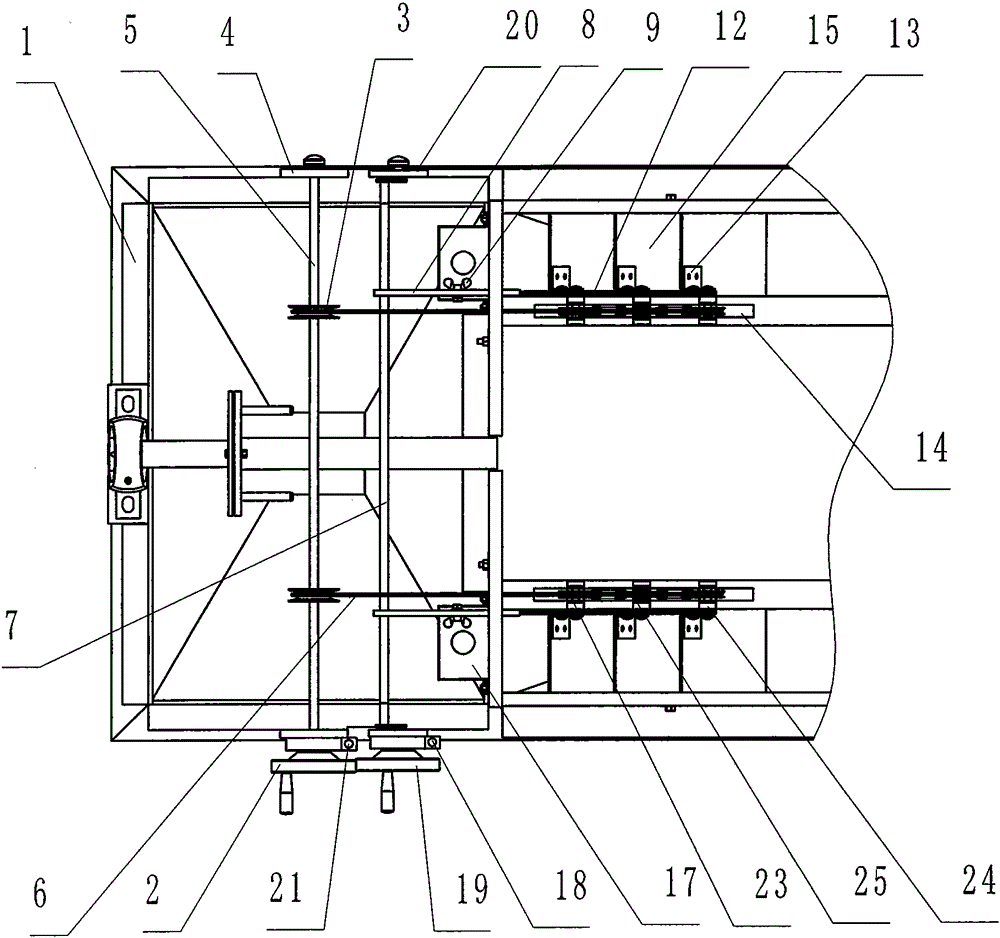

[0020] Embodiment: refer to attached Figure 1-7 , the present invention is made of frame 1, leather case 21, skin dregs separation device, settling ramp device; described leather case 21 is arranged under frame 1, and described skin dregs separation device is located at the leather case 21 upper right part, the settling sloping plate device is arranged on both sides of the skin dregs separation device; the skin dregs separation device is composed of a settling chamber 16, a centrifugal screening part 10 and an overflow tank 17, and the settling chamber 16 Be located on the right side of the leather case 21, the centrifugal screening unit 10 is arranged in the settling chamber 16, the central axis of the centrifugal screening unit 10 is the same height as the frame 1, and the overflow tank 17 is arranged on the side of the settling chamber 16, so The settling swash plate device is composed of a distance control mechanism, an angle control mechanism and a settling swash plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com