Full-automatic peanut shelling and sizing equipment

A fully automatic peanut technology, applied in the direction of shelling, filtering, pod removal, etc., can solve the problems of unsuitable production requirements, inability to grade and screen peanut kernels, etc., to improve efficiency, facilitate widespread application, and ingenious structural design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

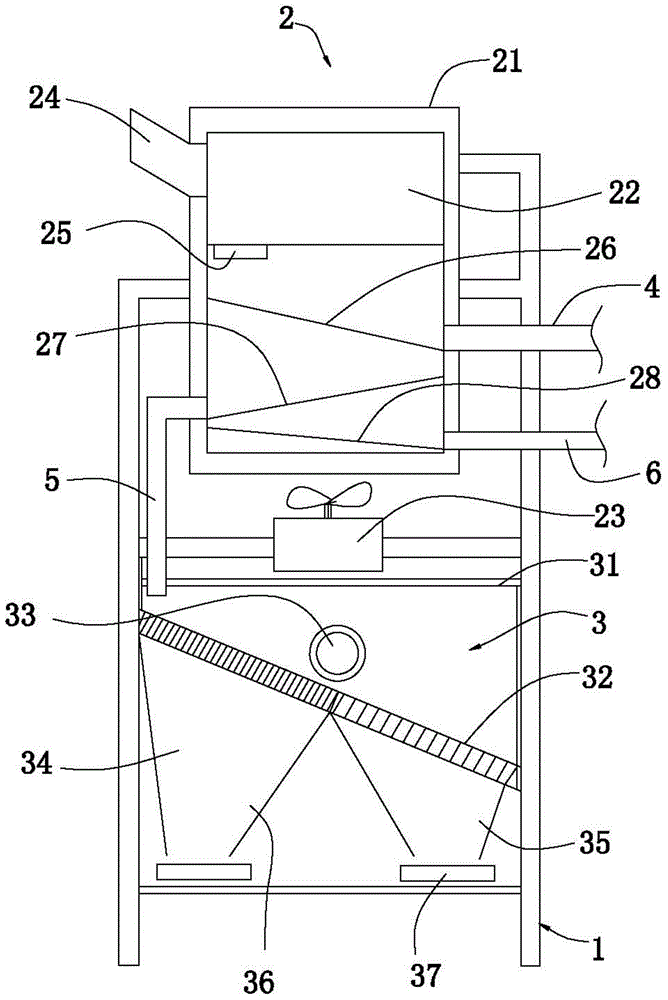

[0014] see figure 1 , a kind of automatic peanut shelling and screening equipment provided in this embodiment includes a main support 1, a shelling mechanism 2 and a grading and screening mechanism 3, and the shelling mechanism 2 is arranged on the upper part of the main support 1, The grading and screening mechanism 3 is arranged on the bottom of the main support 1, and the feed port of the grading and sifting mechanism 3 is connected to the discharge port 5 of the shelling mechanism 2, and the grading and sieving mechanism 3 includes a silo 31 and a grid sieve 32, the bottom material of the hopper 31 is provided with a discharge port, the grid sieve 32 is obliquely arranged on the discharge port of the hopper 31, and a There is a vibrating device 33 that can drive the vibration of the grid sieve 32. The grid sieve 32 is provided with a small material filter screen and a large material filter screen in order from high to low, and corresponds to the small material filter scree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com