Frameless mechanical automatic cycle dust cleaning bag filter

A bag-type dust collector and automatic circulation technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of shortening the cleaning cycle, not being able to stop cleaning, and shortening the life of the filter bag. Filter and dust removal efficiency, prolong service life, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

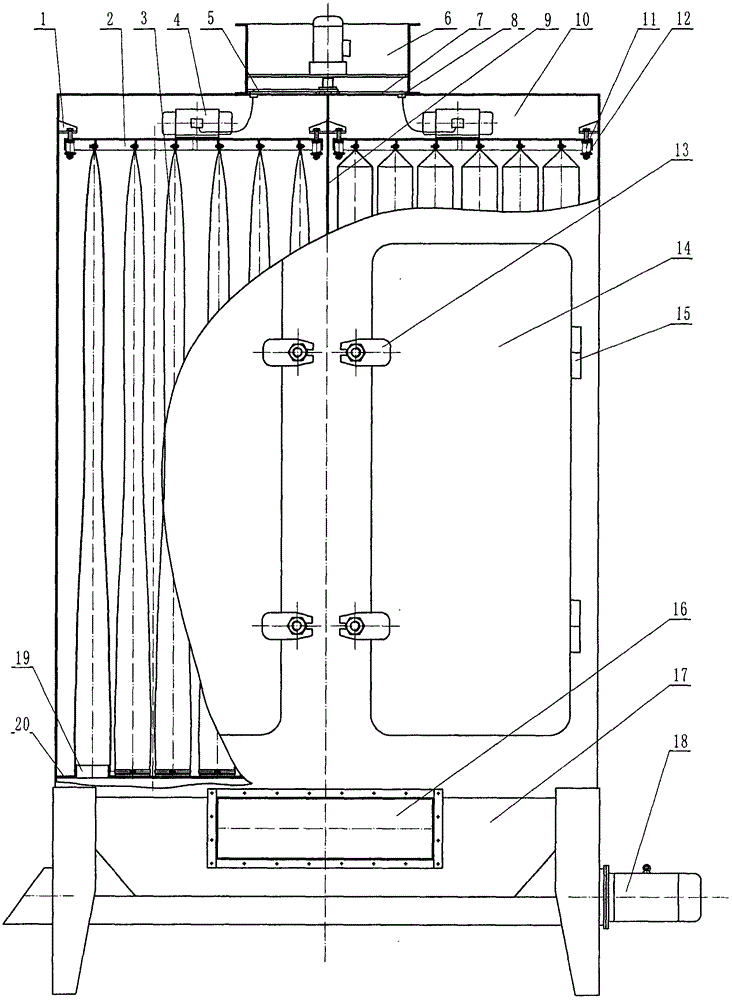

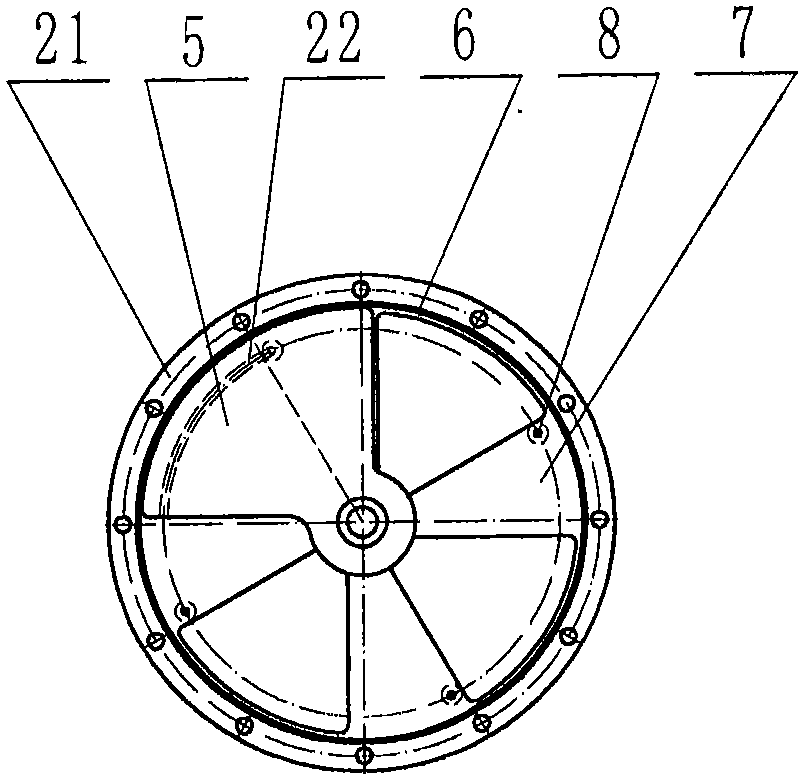

[0014] The present invention as figure 1 As shown, it consists of two parts: a frameless filter bag dust collector and a mechanical automatic cycle dust removal device. Suspension support 1, filter bag vibrating frame 2, filter bag 3, compartment partition 9, dust removal room 10, suspension elastic element 11, filter bag tensioning component 12, door lock 13, inspection door 14, door hinge 15, The air inlet 16, the collection box 17, the ash discharge device 18, the filter bag interface ring 19, and the face plate 20 form a frameless filter bag dust collector. Suspension support 1, filter bag vibrating frame 2, vibrator 4, fan-shaped movable damper 5, dust cleaner shell 6, tuyere distribution plate 7, touch switch 8, suspension elastic element 11, filter bag tensioning assembly 12 to form a mechanical automatic cycle Ash cleaning device.

[0015] The shell of the bag type dust collector of the present invention is composed of a dust removal chamber 10, a compartment partiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com