Synchronous speed regulating device for slitting and rewinding machine of paper disc

A slitting and rewinding and synchronous adjustment technology, which is applied in the directions of winding strips, transportation and packaging, thin material processing, etc., can solve the problem of mechanical coaxial transmission wear, increased number of broken ends of finished paper, and easy tearing of base paper, etc. problem, to achieve the effect of prolonging service life, long service life and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

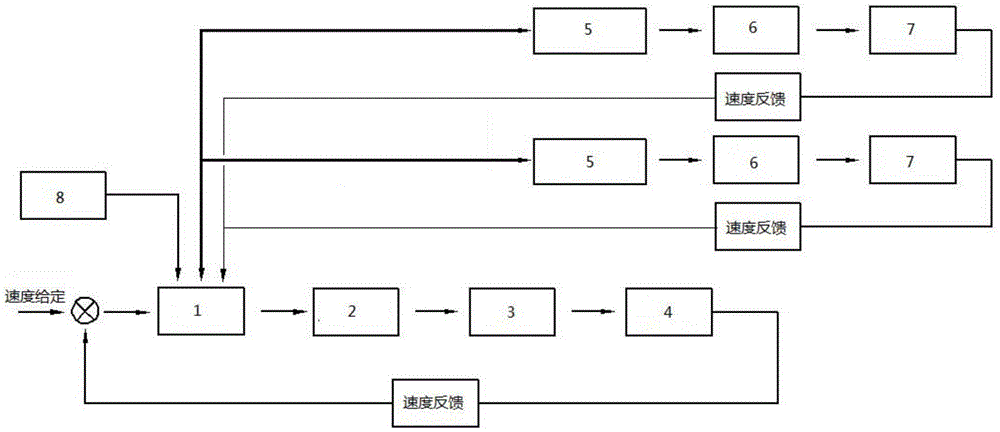

[0041] 1) The main inverter is the power drive of the whole machine, the 1# slave inverter is the paper feeding power of the 1# paper rack, the 2# slave inverter is the paper feeding power of the 2# paper rack, the touch screen is used for parameter correction, and the PLC is used for The system control and the encoder are used for data feedback. This configuration makes the electrical control of the equipment in a complete closed-loop system, thereby fully eliminating the problem of over-tension and under-tension.

[0042] 2) Job requirements:

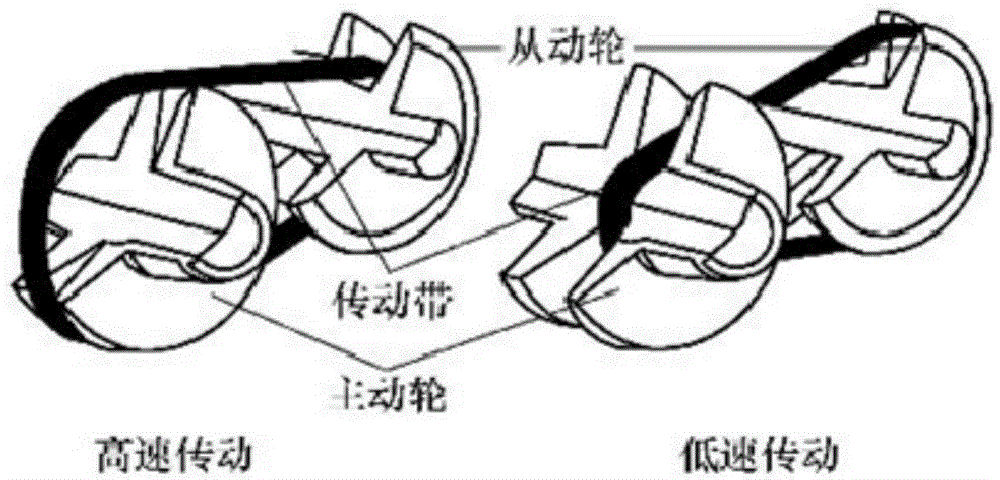

[0043] Tension control refers to the ability to permanently control the tension of the base paper when it is conveyed on the equipment. This control must remain effective for any speed at which the machine operates, including acceleration, deceleration, and constant speed of the machine. Even in the case of emergency shutdown, it should be able to ensure that the cut objects are not damaged. The purpose of tension control can be ach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com