Glass clamping mechanism of fully-automatic backlight assembling machine

A technology of installing glass and clamping mechanism, which is applied in the direction of workpiece clamping device and manufacturing tools, which can solve the problem of glass clamping mechanism peeling and fragility, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

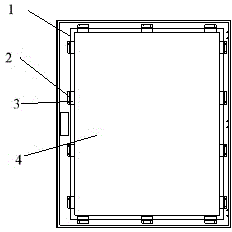

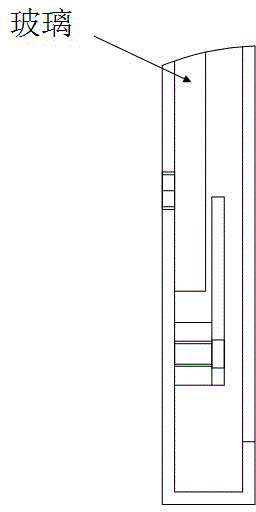

[0008] The glass clamping mechanism of the automatic backlight assembly machine is to fix the door and the glass together, such as figure 1 with 2 As shown, the present invention includes the fixing of the door (1) and the glass (4), and the positional relationship between the clamping block (2) (3) and the glass (4). The clamping block is distributed around the glass, between the clamping block and the glass The contact surfaces of the glass are separated by polyurethane pads, which protects the glass from cracking. Solve the problem of glass punching and fragility.

[0009] The above are only preferred specific embodiments of the present invention, but the scope of protection of the present invention is not limited to this. Anyone familiar with the technical field within the technical scope disclosed in the present invention, according to the technical solution of the present invention Equivalent replacements or changes to its inventive concept should all fall within the protec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com