Combination slip-on steel structure beam platform and prefabricated box girder combined slip-on method

A technology for making beam pedestals and steel structures, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve problems such as uncivilization, difficulties for bridge builders, and impact on quality, so as to achieve reasonable overall structure design, stable overall fixed connections, and easy disassembly and assembled effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

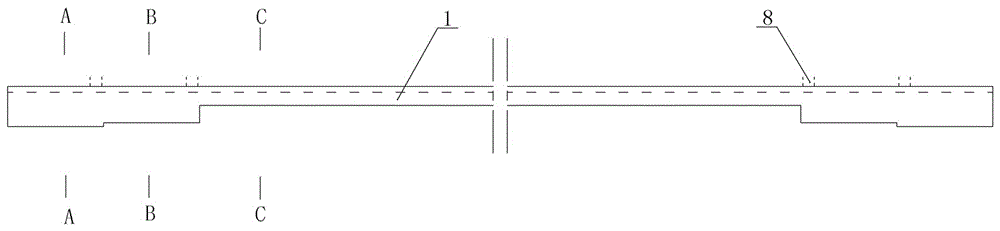

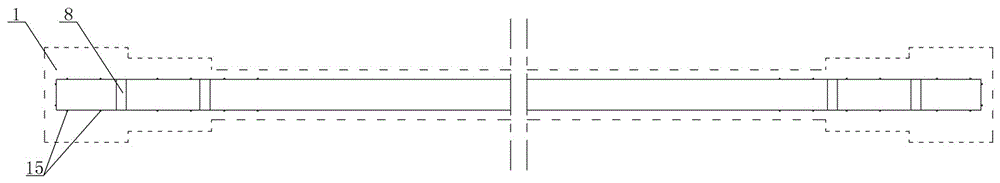

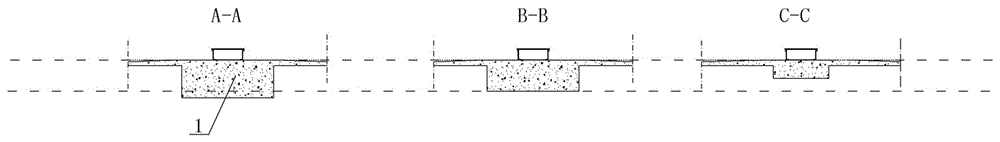

[0037] Embodiment one: see Figure 1-Figure 8 , taking two prefabricated box girders with lengths of 25m and 30m and the same beam bottom width as an example. A combined sleeve-type steel structure beam platform, the bottom of which is a concrete foundation cap 1, and the foundation cap 1 is provided with pre-embedded fixing bolts 15, and the upper part of the fixing bolts 15 is provided with a screw that rotates around the fixing bolts. Pressing plate 16, according to the effect of the downward component force generated by the prestress applied to the prefabricated box girder of two different specifications during the manufacturing process, such as Figure 1-Figure 3 As shown, the concrete thickness of the common segment in the middle is 350mm, the concrete thickness of the assembled segment corresponding to the 25m prefabricated box girder is 800mm, and the concrete of the assembled segment corresponding to the 30m prefabricated box girder The thickness is 900mm, and the la...

Embodiment 2

[0041] Embodiment two: see Figure 1-Figure 8 , a kind of prefabricated box girder composite punching method using the steel structure beam pedestal described in Embodiment 1, comprising the following steps:

[0042] (1) According to the different types of prefabricated box girders that need to be built, determine the layout type of the foundation cap of the prefabricated yard, and at the same time follow the principle of the length of the shared segment as long as possible and the reasonable combination of the assembled segments to carry out the steel structure beam platform the design of;

[0043] (2) Arrangement of the foundation cap: According to the stress of each section of the foundation cap corresponding to different box girder types in the box girder manufacturing process, the construction of each section of the foundation cap is carried out, such as Figure 1-Figure 3 As mentioned above, the concrete thickness of each section is reasonably designed to meet the force...

Embodiment 3

[0047] Embodiment three: see Figure 1-Figure 8 , the structure of this embodiment is basically the same as that of Embodiment 1, and the similarities will not be repeated. Step (5), until all the box girder types of the combined package are completed.

[0048] According to the needs of working conditions, when several different types of box girders need to be prefabricated alternately, for example, 20 pieces of 30m box girders are made first, and then 10 pieces of 25m box girders are made. When the 30m box girder is being manufactured, the gantry crane is used to reasonably carry out the assembly and assembly of the steel structure girder pedestal, and the combination of different types of prefabricated box girders is carried out in an orderly manner.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com