Satellite structure for platform and load integration

A satellite structure and load technology, applied in the aerospace field, can solve problems such as high structural redundancy, large volume, and heavy system quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

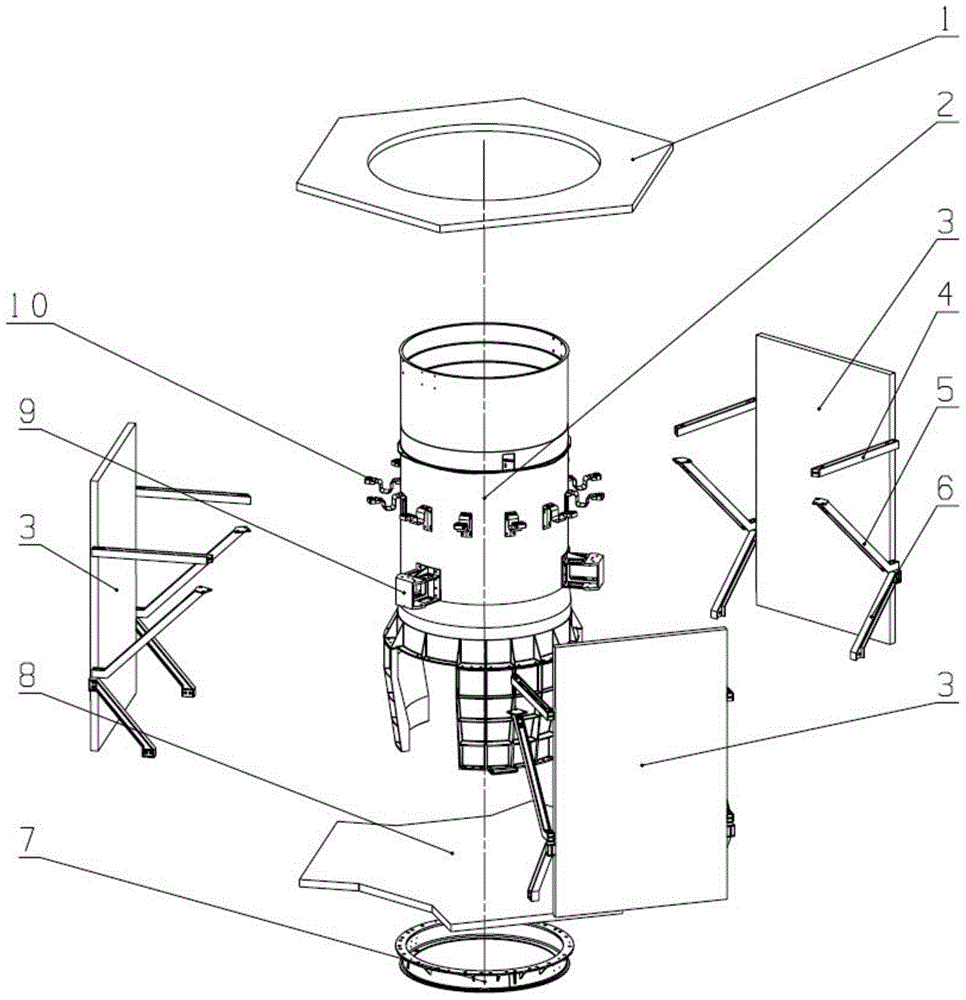

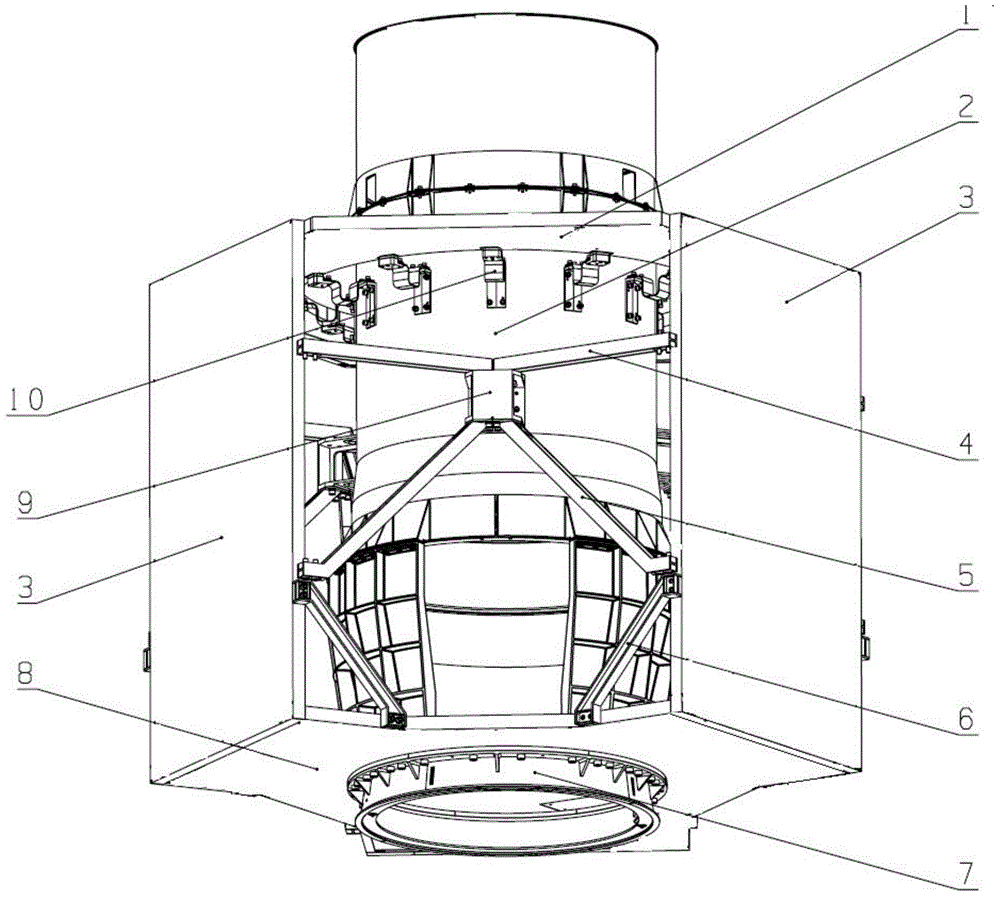

[0018] Specific implementation mode 1. Combination figure 1 with figure 2 Describe this embodiment, the satellite structure used for platform load integration, the structure consists of an upper plate 1, a central bearing cylinder 2, a side plate 3, a docking ring 7, a bottom plate 8, three rod brackets 9 and twelve upper plates The bracket 10 is composed.

[0019] Taking the docking ring 7 as the assembly reference, the docking ring 7 adopts the standard star-arrow interface and is made of aluminum; the base plate 8 is installed on the docking ring 7, and the base plate 8 adopts a honeycomb sandwich structure. The advantage of the honeycomb sandwich structure is that it is light in weight and relatively High rigidity; the central load-bearing tube 2 is installed on the bottom plate 8, and the central load-bearing tube 2 is made of carbon fiber composite materials. They are not only the main load-bearing structure of the satellite, but also play the role of eliminating misce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com