Lithium electric inserting plate type management container

A plug-in type and plug-in technology, which is applied in storage containers, grading, and management fields, can solve the problems of low efficiency, large errors, and many workers, and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

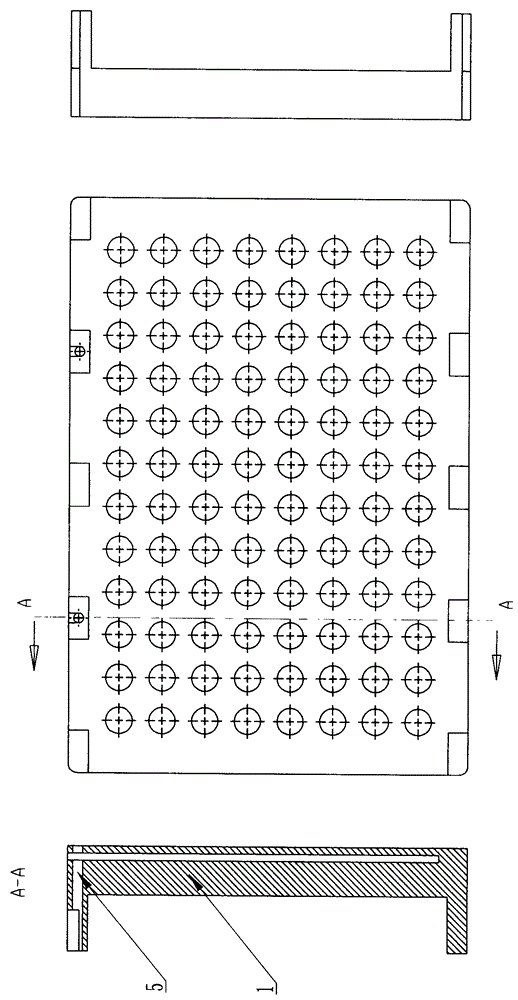

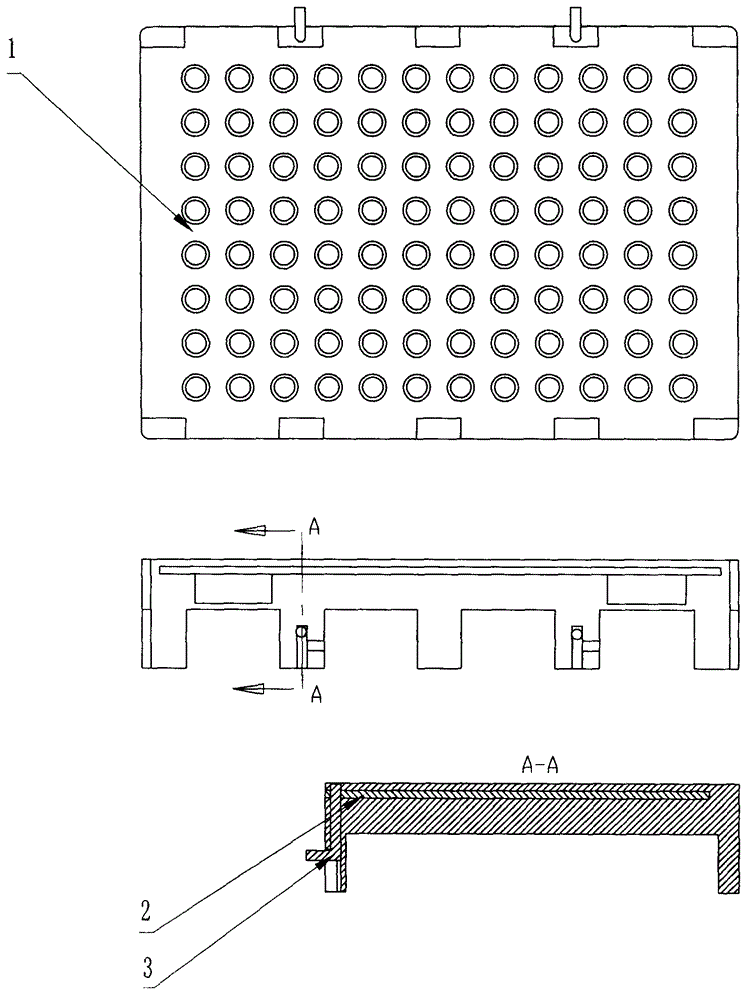

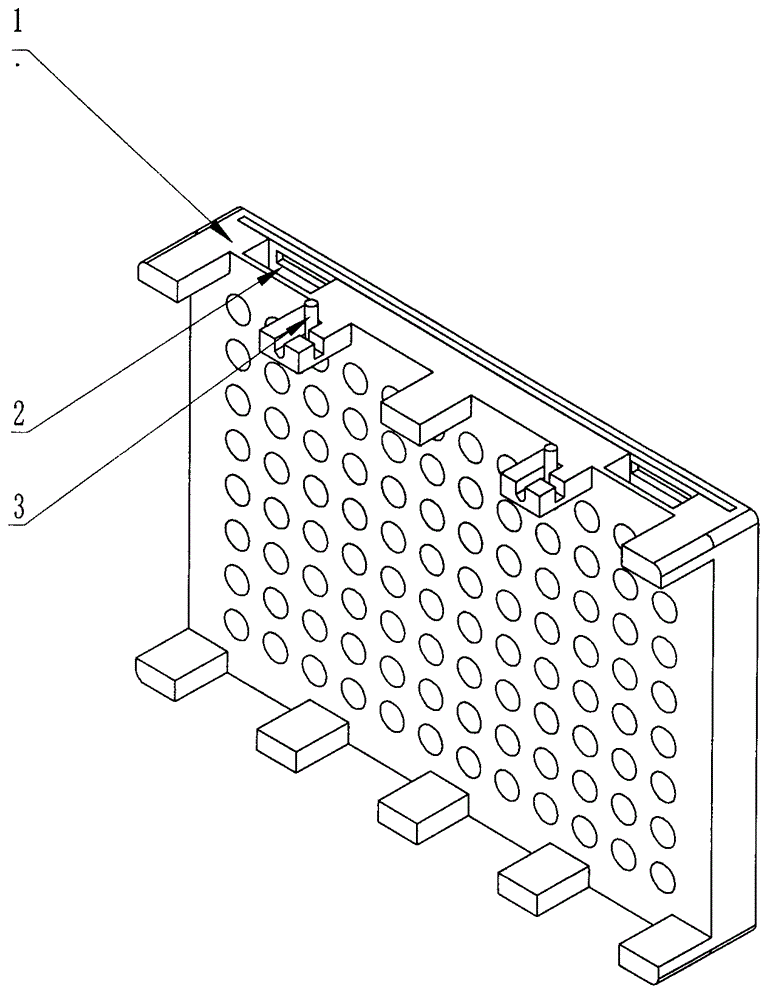

[0023] The invention is a lithium battery plug-in type management container, such as figure 1 , 2 , 3, 4, 5, and 6, including: container body 1, inserting plate 2 and pin 3; There are H through holes with the number of columns N, the spacing C, the number of rows M, and the spacing D; E blocks are raised on the top surface of the square body near any two opposite sides; The opposite face of the through hole in the square array on the top face of the square body is the bottom face; the face connected to the top face and the bottom face of the square body is the end face, and a rectangle is formed in the middle of one end face by stretching and cutting a certain depth toward the end face opposite to the end face. A rectangular hole, the rectangular hole communicates with the through-holes of the rectangular array on the top surface, this end surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com