Novel wringing roller changing device

A roll changing device and roll drying technology, which is applied in transportation and packaging, metal processing, load hanging components, etc., can solve the problems of time-consuming and labor-intensive adjustment of the counterweight by twisting the screw by the hand wheel, and the inability to fix the shaft head stably, etc., to achieve The effect of avoiding waste and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

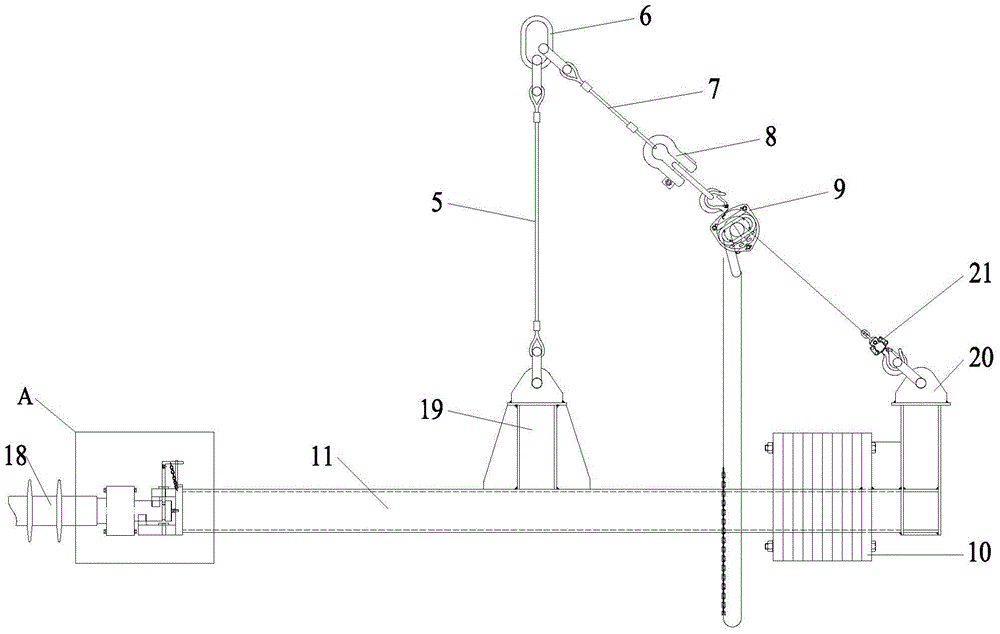

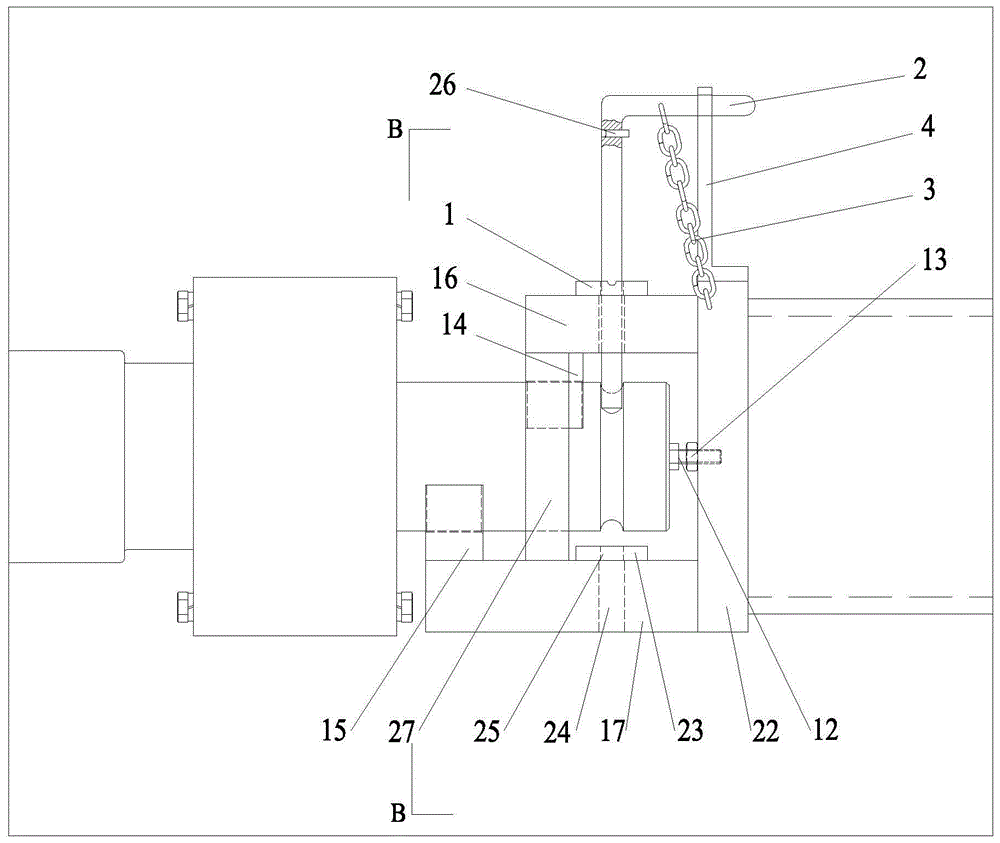

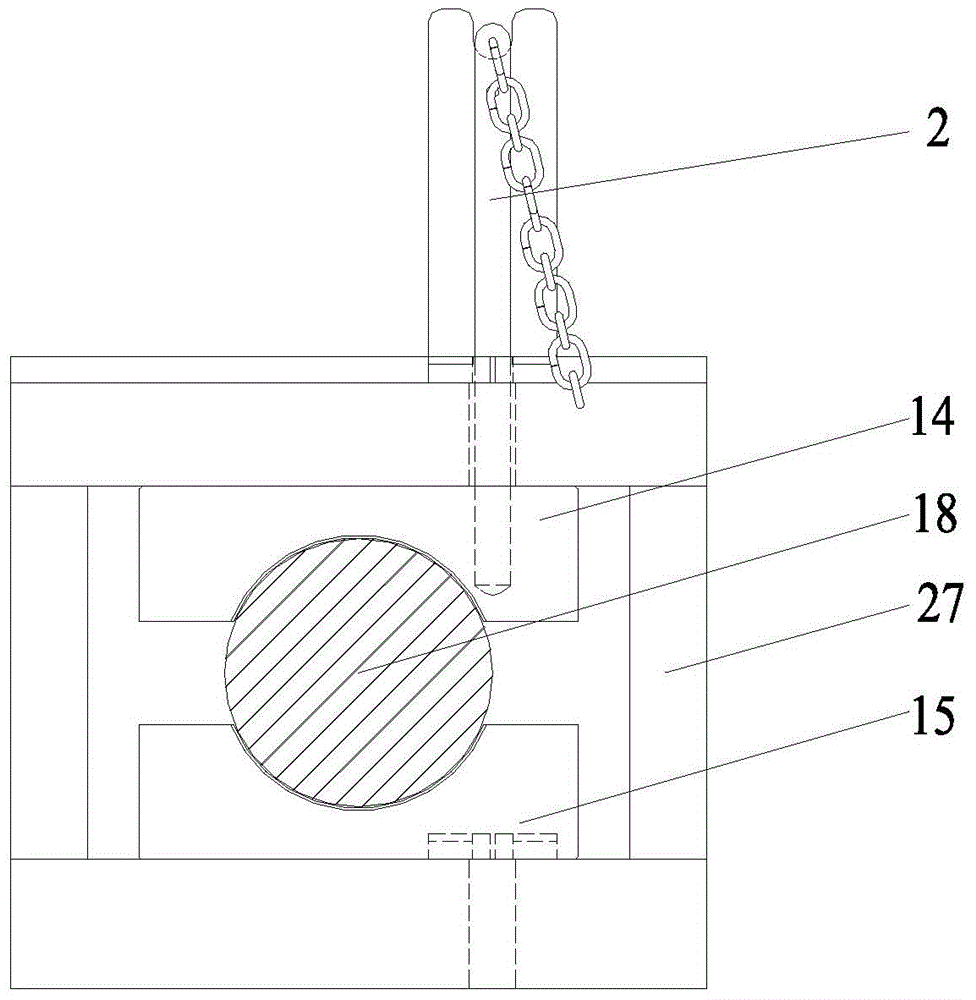

[0024] Such as figure 1 A novel extrusion roller changing device shown includes a shaft head fixing mechanism, a hoisting beam 11 and a drag mechanism driven by a crane, and the shaft head fixing mechanism is fixedly installed on one end of the hoisting beam 11 ( figure 1 middle left end), the other end of the hoisting beam 11 is provided with a counterweight 10; the middle part of the hoisting beam 11 is provided with a first hoisting platform 19, and the counterweight end of the hoisting beam 11 is also provided with a second hoisting platform 20; the drag mechanism It includes the suspension ring 6 that needs to be hung on the crown block when changing the roll, as well as the shackle 8 and the hook 21. The suspension ring 6 is connected to the shackle 8 through a short steel wire rope 7, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com