A kind of polyester composition for reflecting plate

A composition and reflective plate technology, applied in the field of polymer materials, can solve the problems of unfavorable high temperature resistance and discoloration, affecting the curing effect of silica gel, etc., and achieve the effects of good mold filling fluidity, good curing, and low yellowing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

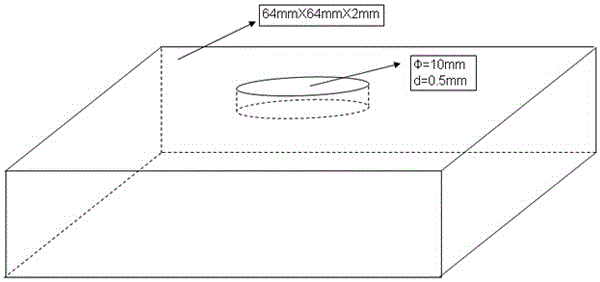

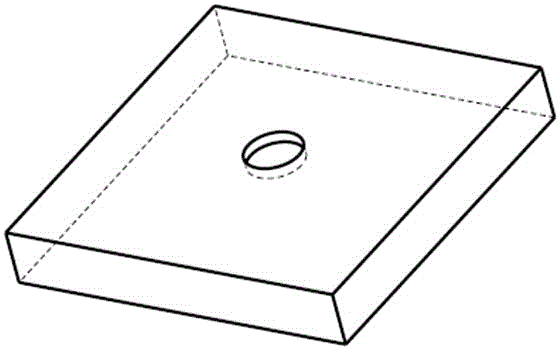

Image

Examples

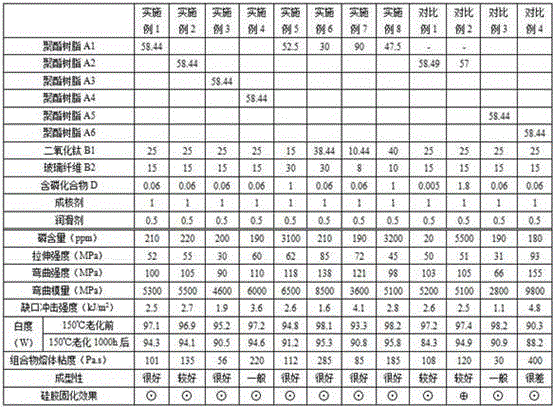

Embodiment 1~8 and comparative example 1~4

[0053] Embodiment 1~8 and comparative example 1~4: the preparation of polyester composition and sample

[0054] Use a high-speed mixer to mix the dried polyester resin with phosphorus-containing compounds, nucleating agents, lubricants, etc., and add it from the main feeding port of the twin-screw extruder, and add titanium dioxide and glass fiber to the twin-screw through the side feeder extruder, at a set temperature of 200-300°C, melt extrusion and granulation through a twin-screw extruder to obtain a granular polyester composition; then dehumidify and dry the obtained granular polymer composition at 110°C for 5 hours, and then At the set temperature of 240~305°C, the samples required for the relevant mechanical properties, whiteness and silicone curing tests were prepared by injection molding. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com