Polycarbonate composite material and preparation method thereof

A polycarbonate and composite material technology, applied in the field of polymer materials, can solve the problems of poor surface gloss and poor fluidity, and achieve the effects of good dimensional stability, simple formula and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

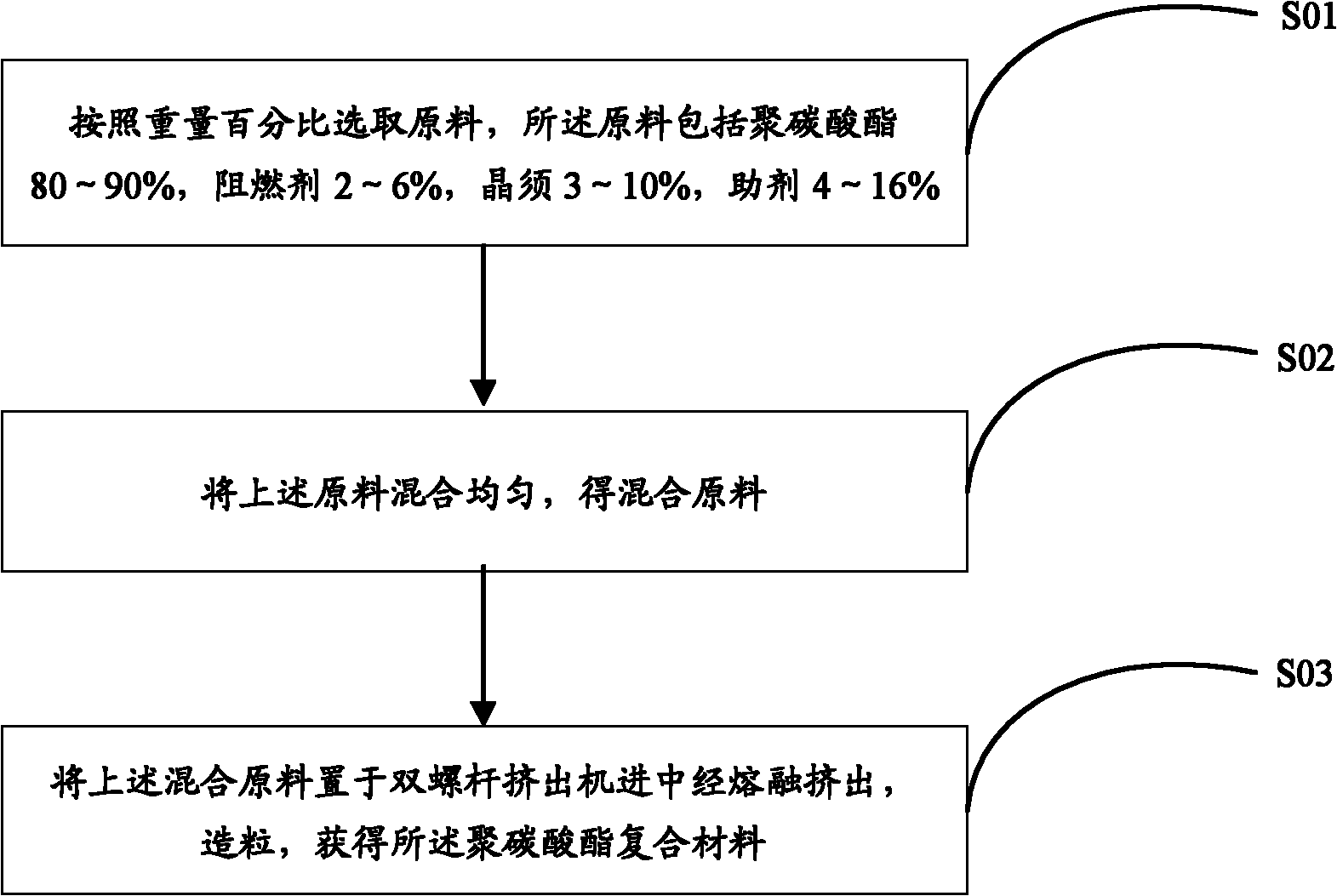

Method used

Image

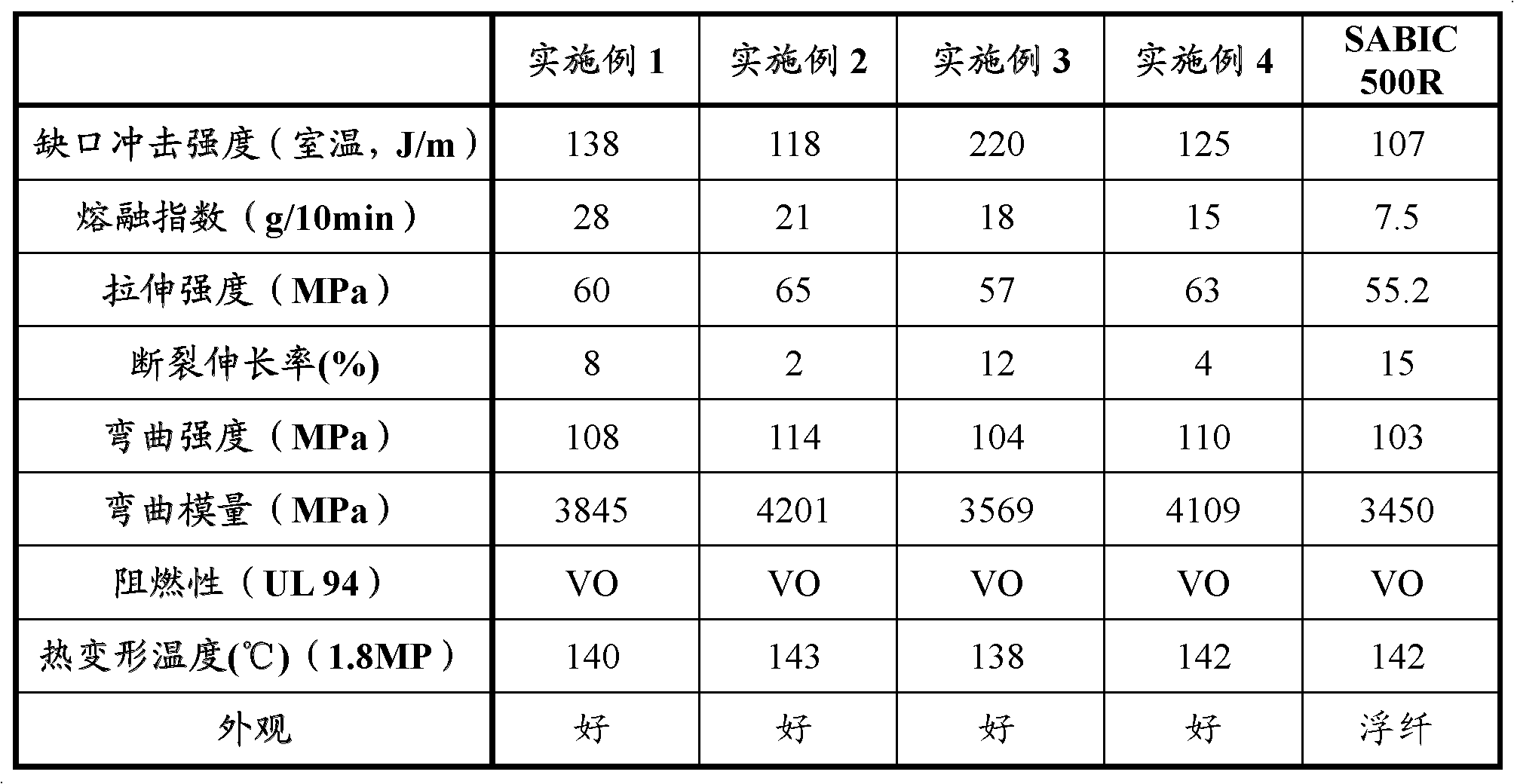

Examples

Embodiment 1

[0043] Components and weight percentages thereof of the polycarbonate composite material of the present embodiment are:

[0044] Polycarbonate 80%;

[0045] Flame retardant 5%;

[0046] Whiskers 5%;

[0047] Auxiliary 10%.

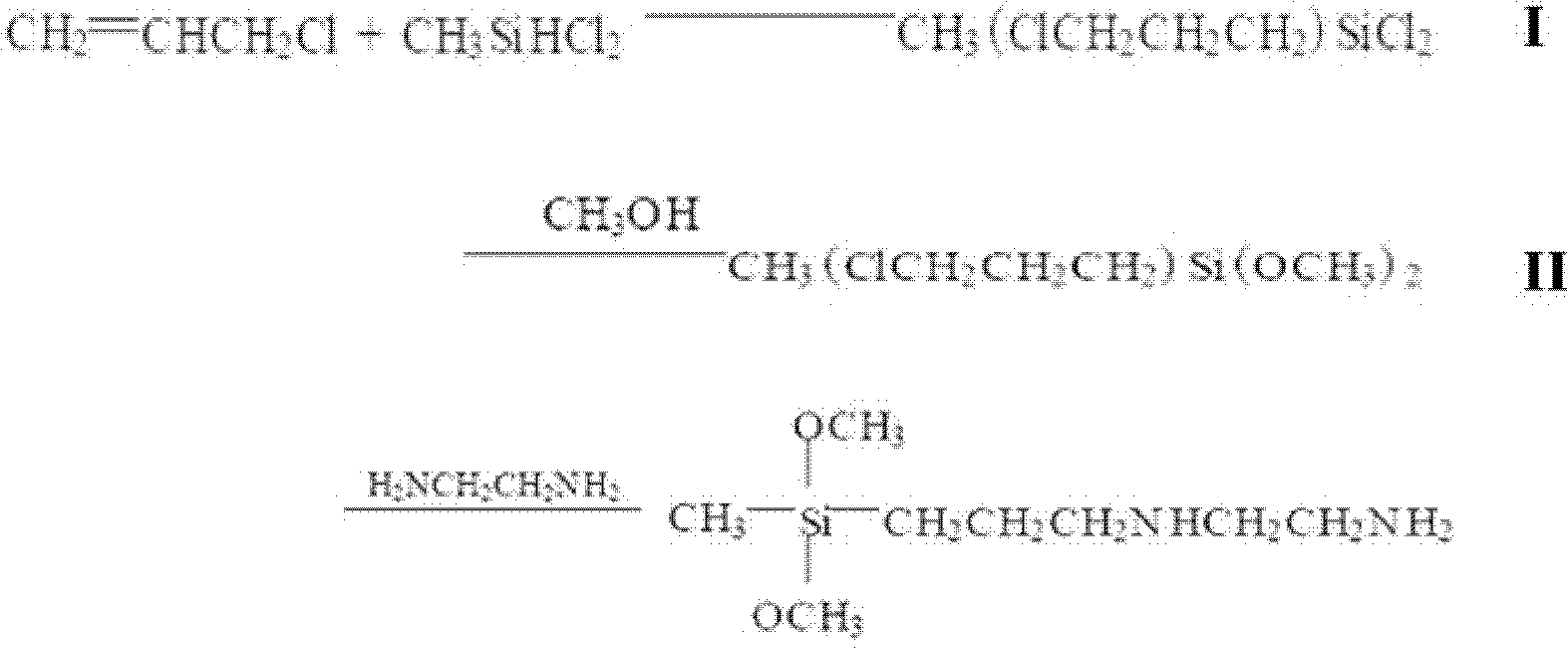

[0048]Among them, polycarbonate has a refractive index of 1.58 to 1.61, a transmittance of 88% to 90%, and a melt index of 10 to 30g / 10min (test conditions: 300°C / 1.2Kg); the flame retardant is an additive containing bromine and nitrogen. Type flame retardant; whisker is a mixture of calcium carbonate whisker and whisker silicon, its weight ratio is 1:1; additives include toughening agent, silane coupling agent, lubricant, antioxidant and flame retardant anti-dripping Dropping agent, based on 100% of the polycarbonate composite material gross weight, the weight percentages of the toughening agent, silane coupling agent, lubricant, antioxidant and flame retardant anti-dripping agent are respectively as follows:

[0049] Toughener 4%;

[0050] Silane co...

Embodiment 2

[0071] Components and weight percentages thereof of the polycarbonate composite material of the present embodiment are:

[0072] Polycarbonate 83%;

[0073] Flame retardant 3%;

[0074] Whiskers 8%;

[0075] Auxiliary 6%.

[0076] Among them, polycarbonate has a refractive index of 1.58 to 1.61, a transmittance of 88% to 90%, and a melt index of 10 to 30g / 10min (test conditions: 300°C / 1.2Kg); the flame retardant is an additive containing bromine and nitrogen. Type flame retardant; whisker is the mixture of calcium carbonate whisker and whisker silicon, and its weight ratio is 1: 1, and calcium carbonate whisker adopts the preparation method of calcium carbonate whisker in embodiment 1; Auxiliary agent comprises toughening agent , silane coupling agent, lubricant, antioxidant and flame retardant anti-dripping agent, based on 100% of the total weight of the polycarbonate composite material, the toughening agent, silane coupling agent, lubricant, antioxidant The weight percen...

Embodiment 3

[0085] Components and weight percentages thereof of the polycarbonate composite material of the present embodiment are:

[0086] Polycarbonate 86%;

[0087] Flame retardant 2%;

[0088] Whiskers 4%;

[0089] Auxiliary 8%.

[0090] Among them, polycarbonate has a refractive index of 1.58 to 1.61, a transmittance of 88% to 90%, and a melt index of 10 to 30g / 10min (test conditions: 300°C / 1.2Kg); the flame retardant is an additive containing bromine and nitrogen. Type flame retardant; whisker is the mixture of calcium carbonate whisker and whisker silicon, and its weight ratio is 1: 1, and calcium carbonate whisker adopts the preparation method of calcium carbonate whisker in embodiment 1; Auxiliary agent comprises toughening agent , silane coupling agent, lubricant, antioxidant and flame retardant anti-dripping agent, based on 100% of the total weight of the polycarbonate composite material, the toughening agent, silane coupling agent, lubricant, antioxidant The weight percen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com