Yarn creel of multi-axis warp knitting machine

A warp knitting machine, multi-axial technology, applied in warp knitting, textiles, papermaking, knitting, etc., can solve the problems of high resistance to pulling out and putting in the yarn, yarn breakage, and large sliding friction of the yarn shaft , to achieve the effect of preventing yarn breakage, reducing friction and reducing drawing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

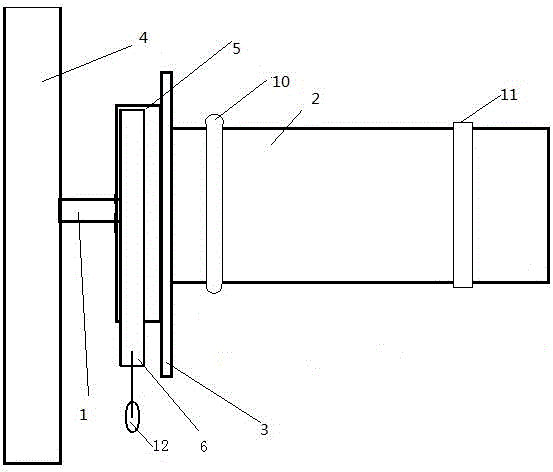

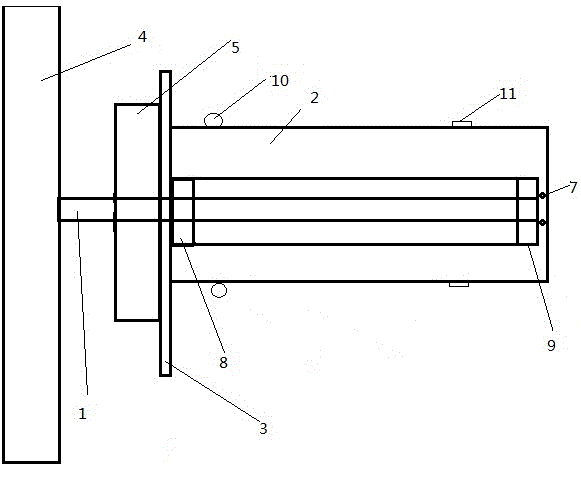

[0023] A creel for a multiaxial warp knitting machine, such as figure 1 , figure 2 , including a base 1, a yarn shaft 2, a yarn baffle 3, a bearing group, a brake disc 5, a brake pad 6 and a retaining ring 7, the bearing group includes a bearing one 8 and a bearing two 9 with the same structure, and the bearing one 8 is arranged close to The position of the creel support 4, the base 1 passes through the brake disc, the yarn baffle plate 3, the bearing one 8, the bearing two 9, the retaining ring 7, the bearing two 9 is fixed by the retaining ring 7, and the middle part of the yarn shaft 2 is provided with a circle In the cylindrical inner cavity, bearing one 8 and bearing two 9 are respectively embedded in the two ends of the inner cavity of the yarn shaft 2, and the two ends of the yarn shaft 2 are covered with rubber ring one 10 and rubber ring two 11 respectively, and the weight 12 Connected to the brake pad 6, the brake disc 5 is in contact with the brake pad 6, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com