Measuring device for calibrating high-speed railway track measuring instrument

A technology for high-speed railways and measuring devices, applied in the direction of railway vehicle shape measuring devices, measuring instruments, rails, etc., can solve problems affecting measurement accuracy, etc., and achieve the effects of avoiding measurement errors, simple operation, and reasonable and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in combination with specific embodiments.

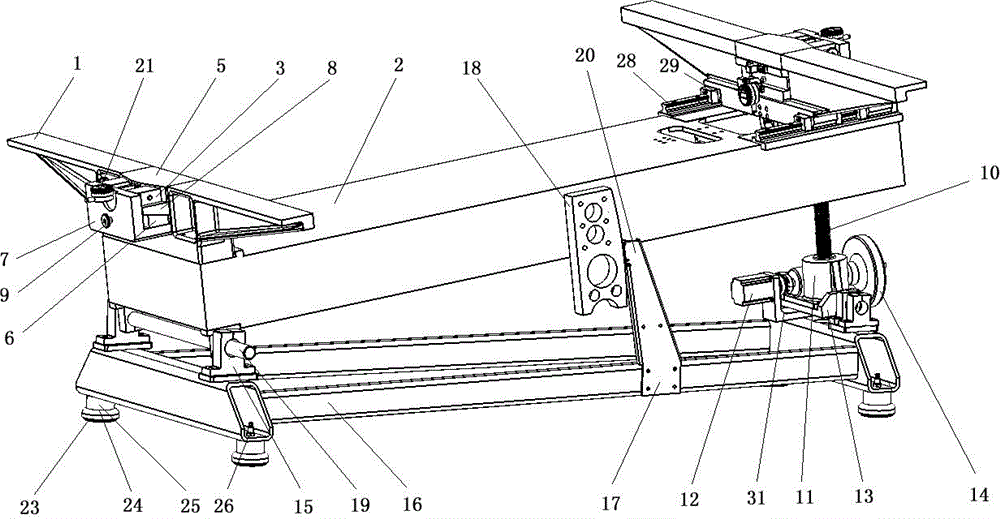

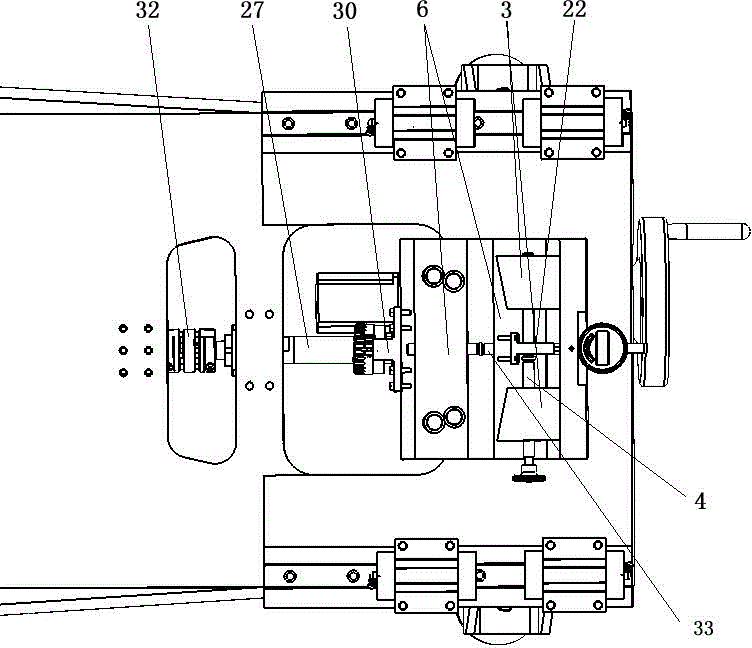

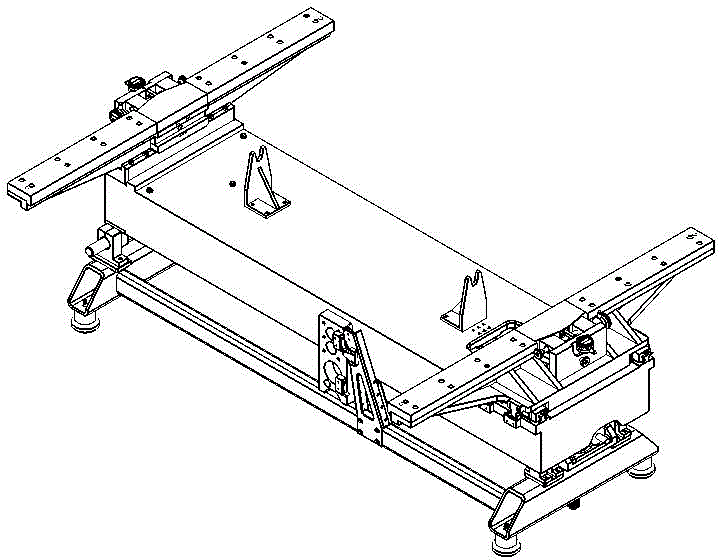

[0028] The present invention relates to a measuring device for testing a high-speed railway track measuring instrument, which includes a welding base 16, a super-elevation testing module, a cast structure girder 2 and a gauge testing module from bottom to top, and the gauge testing module includes a fixed end and a movable The ends are placed parallel to both sides of the cast structural girder 2, and the cast structural girder 2 is perpendicular to the rail direction.

[0029] The ultra-high verification module includes an ultra-high lead screw 10 , an elevator 11 , an optical axis support 15 , a steel plate support 17 for an arc grating measuring head, an arc block 18 , an optical axis 19 and a grating reading head 20 . A pair of optical axis supports 15 is arranged between the bottom of one end of the cast structural girder 2 and the welding base 16, and an optical axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com