Freezer with adjustable freezing section length and freezing method for freezer

A freezing method and freezer technology, which is applied in the direction of earthwork drilling, shaft equipment, mining equipment, etc., can solve the problems that the position of the freezing pipe heat insulation device cannot be adjusted and cannot be satisfied, and achieves the improvement of effective utilization rate, simple structure, and good performance. The effect of thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

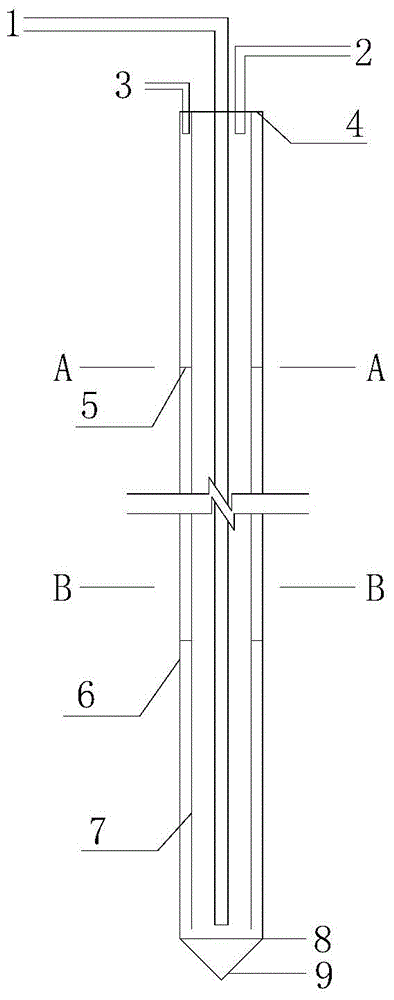

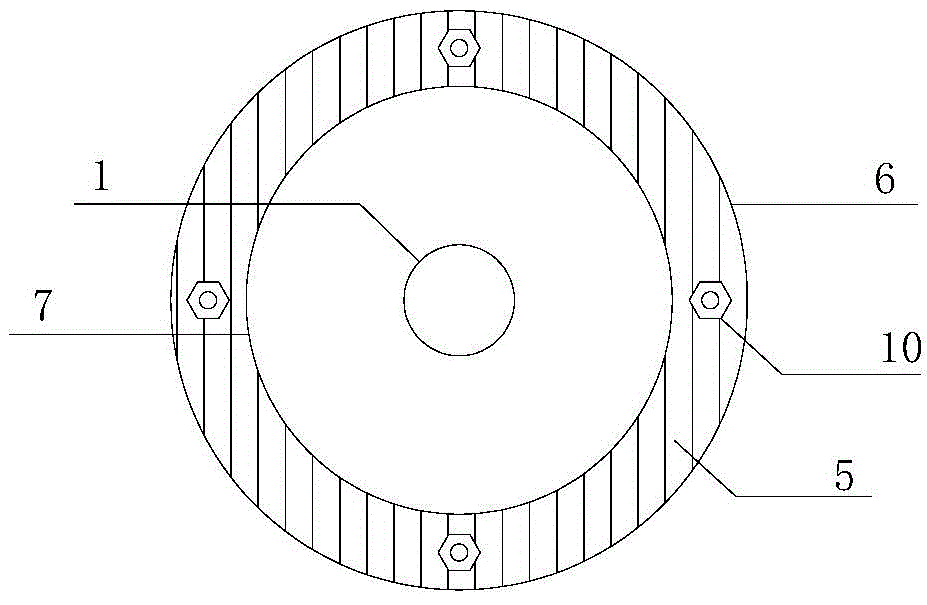

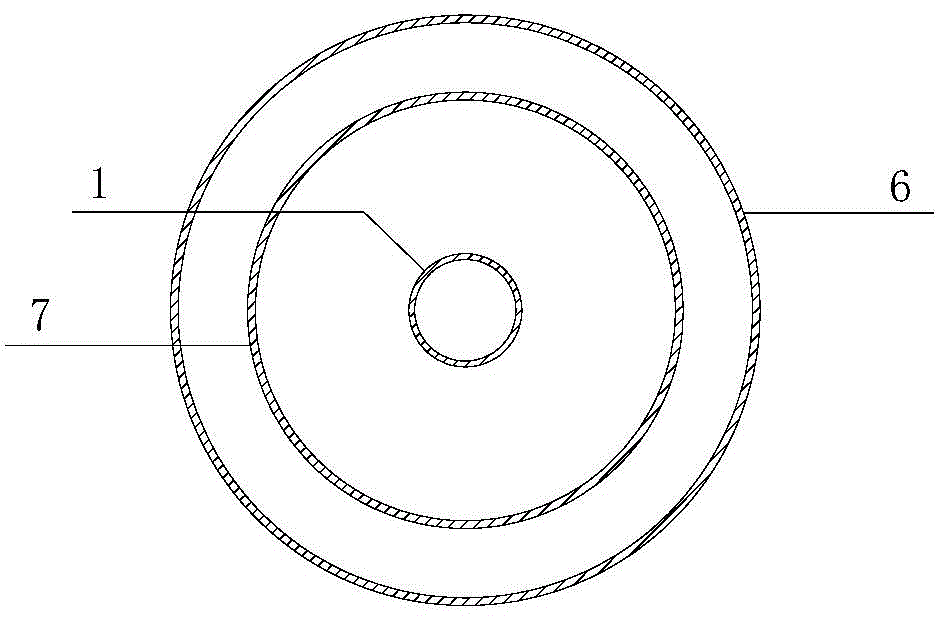

[0019] Such as figure 1 Shown is a freezer with adjustable freezing section length, which includes a liquid supply pipe 1, a liquid return pipe 2, an auxiliary pipe 3, an inner freezing pipe 7, an outer freezing pipe 6, and several annular partitions 5; the inner freezing pipe 7 is set Inside the outer freezing tube 6, the tops of the inner freezing tube 7 and the outer freezing tube 6 are sealed simultaneously by the upper sealing plate 4, and the bottom end of the outer freezing tube 6 is sealed by the lower sealing plate 8, and the bottom end of the inner freezing tube 7 is shorter than the outer freezing tube. At the bottom of the tube 6, the inner freezing tube 7 and the outer freezing tube 6 are only connected at the bottom; the annular partition 5 is arranged at intervals in the axial direction in the cavity formed by the inner freezing tube 7 and the outer free...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com