Cleaning type brake shoe

A brake pad and cleaning technology, applied in the direction of friction linings, mechanical equipment, etc., can solve the problems of wear of brake pads and brake discs, affecting the braking effect of brake pads, etc., and achieve the effect of improving braking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below, the technical solution of the present invention will be described in detail through specific examples.

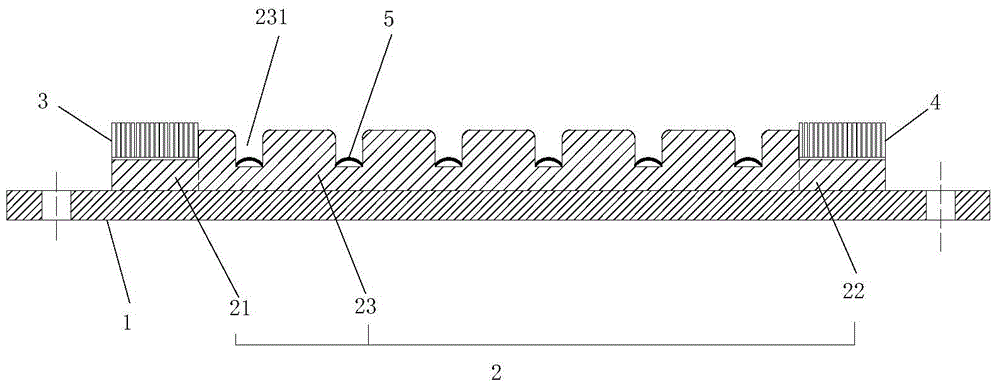

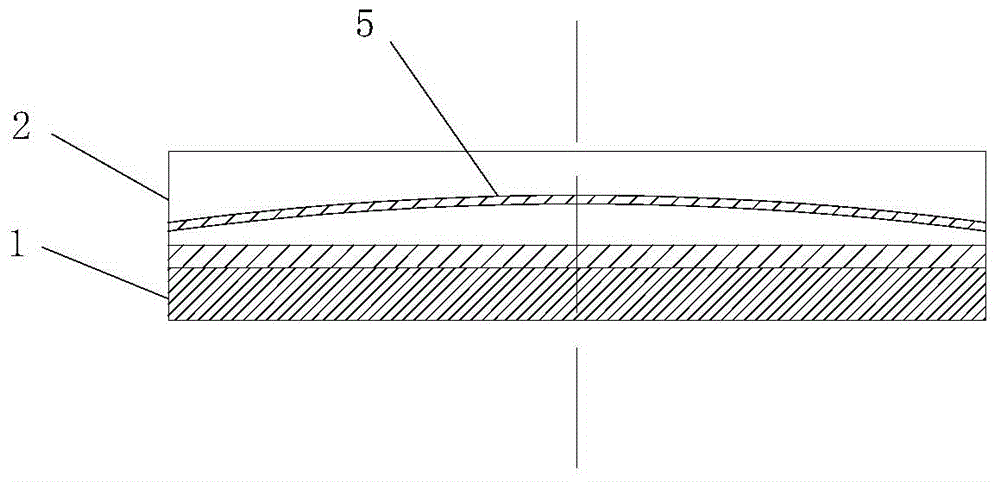

[0013] Such as Figure 1-2 as shown, figure 1 It is a schematic structural diagram of a detachment-preventing heat dissipation friction sheet proposed by the present invention; figure 2 It is a vertical cross-sectional view of a diaphragm in a detachment-preventing heat dissipation friction sheet proposed by the present invention.

[0014] refer to Figure 1-2 , a detachment-preventing heat dissipation friction sheet proposed by an embodiment of the present invention includes: a liner 1 and a friction sheet 2 fixed to the liner 1, wherein the friction sheet 2 includes a first step 21, a second step 22 and a The friction platform 23 between the first step platform 21 and the second step platform 22, the first step platform 21, the second step platform 22 and the friction platform 23 are integrally formed, and the platforms of the first step platform 21 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com