Sintering machine inspecting and maintaining method

A technology of sintering machine and machine table, which is applied in the field of metallurgy to achieve the effect of reducing labor intensity of workers, reducing inspection and maintenance time, and eliminating potential safety hazards

Active Publication Date: 2015-05-27

LIUZHOU IRON & STEEL

View PDF2 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The technical problem to be solved by the present invention is to provide an inspection and maintenance method for a sintering machine. This inspection and maintenance method for a sintering machine can solve the problem of keeping a vacancy when the trolley group of the sintering machine moves on the track of the sintering machine, so that it is convenient for all parts of the sintering machine to be carried out at the same time. Check for maintenance issues

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

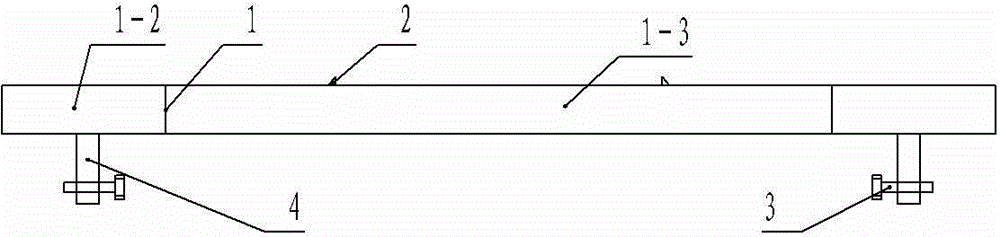

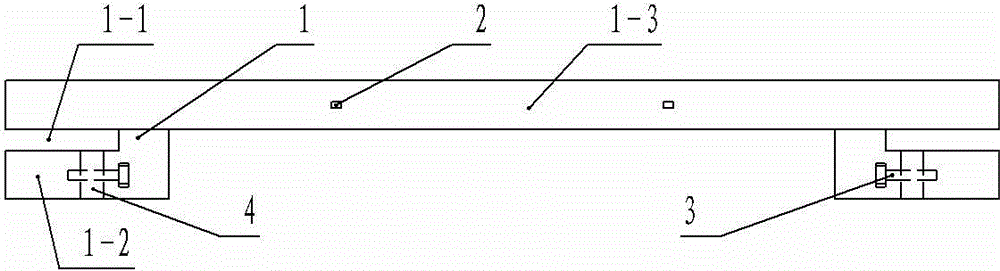

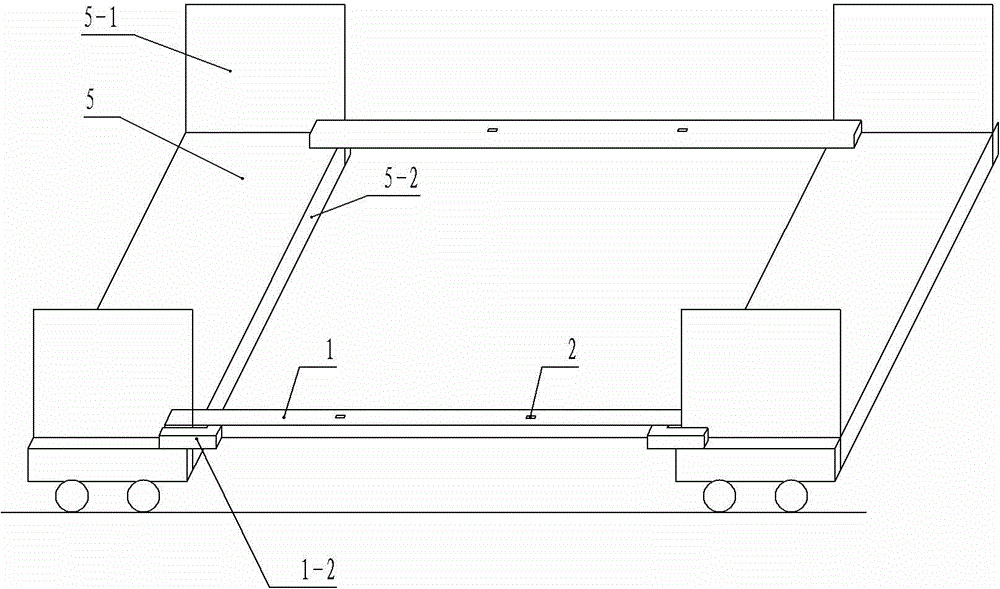

[0034] The length of the main rod 1 is twice the width of the sintering machine trolley 5; the width of the slot 1-1 is 10 cm; lift out two sintering machine trolleys in step a; lift out two sintering machines in step c Pallet; All the other are identical with embodiment one.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a sintering machine inspecting and maintaining method and belongs to the technical field of metallurgy. A sintering machine maintaining stay bar is utilized, the vacancy maintained by the sintering machine maintaining stay bar in the sintering machine trolley group corresponds to the part of the sintering machine to be inspected and maintained by means of rotation of an annular conveying belt of the sintering machine, so that enough inspection and maintenance space can achieved on the part. By means of the method, the vacancy is maintained when the sintering machine trolley group moves on a sintering machine track, and all parts of the sintering machine can be inspected and maintained simultaneously.

Description

technical field [0001] The invention relates to the technical field of metallurgy, in particular to an inspection and maintenance method for a sintering machine. Background technique [0002] Sintering production is one of the important processes in steel production. The existing sintering method is to use a belt sintering machine, such as Figure 4 The shown sintering machine includes a sintering machine trolley group 12 connected sequentially by a plurality of sintering machine trolleys arranged on the upper side belt surface slideway 13 of the endless conveyor belt 18, between the upper side belt of the endless conveyor belt 18 The lower arrangement is provided with a plurality of bellows groups 14 corresponding to the trolley group 12 of the sintering machine with upward openings, an ignition device 15 is arranged at the head of the sintering machine and the head of the slideway 13 is connected to the head of the bellows group 14. The first sealing plate 16 for sealing t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F27B21/00

Inventor 陈有升阮志勇吴丹伟莫龙桂刘巍曹明树韩正轩孙火荣韦鹏覃峰

Owner LIUZHOU IRON & STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com