Resistance type temperature sensor verification system and method

A temperature sensor, resistive technology, applied in the field of temperature sensor verification, can solve the problems of inaccurate results, verification results error, large verification result error, etc., to achieve the effect of simplifying the verification operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] In order to describe the technical features and effects of the present invention in detail, and can be implemented in accordance with the content of this specification, the following further describes the embodiments of the present invention in conjunction with the accompanying drawings.

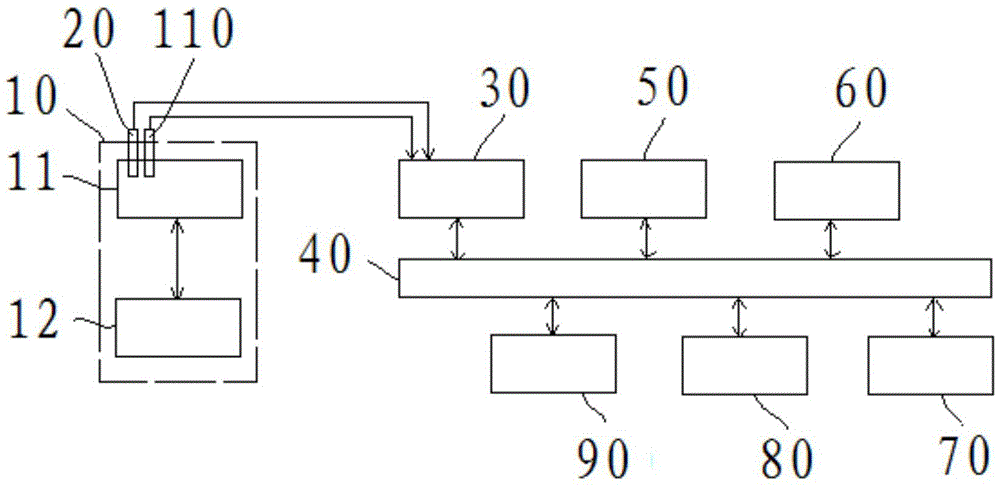

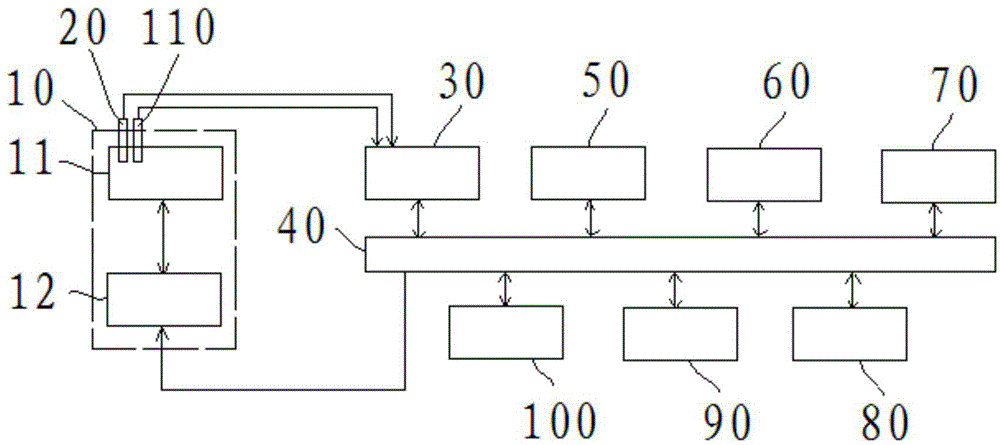

[0077] figure 1 Illustratively shows an embodiment of an exemplary resistance temperature sensor calibration system in which the system according to the present invention is suitable for implementing the various embodiments described herein. The resistance temperature sensor verification system includes a thermostat 10, a standard resistance temperature sensor 20, a data collector 30, a first communication interface module 40, a processing circuit 50, a verification task management module 60 and a verification result generation module 70. The first communication interface module 40 is coupled to the data collector 30, the processing circuit 50, the verification task management module 60, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com